Titanium scrap recycling and remelting technology

A remelting and process technology, applied in the direction of improving process efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

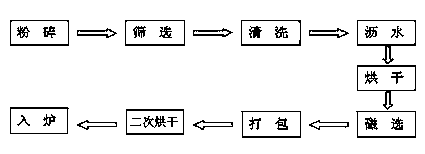

[0016] The titanium scrap recycling and remelting process of the present invention is: crushing→screening→cleaning→draining→drying→magnetic separation→packing→secondary drying→putting into the furnace.

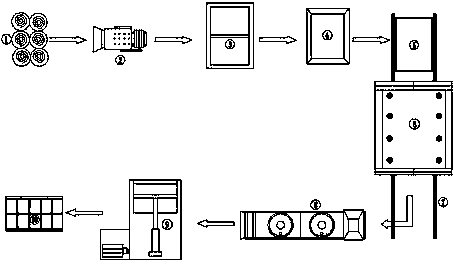

[0017] The above-mentioned titanium scrap recovery and remelting process, the steps of the titanium scrap recycling and remelting process are: the spiral ribbon-shaped scrap material 1 loaded in the sponge titanium bucket first needs to be processed into scraps by a metal pulverizer 2, and then needs to be processed into scraps. Ultrasonic cleaning machine 3 cleans and removes oil stains. After comparing various cleaning methods, it is determined that ultrasonic cleaning is the most practical method. Finally, rinse the residual detergent, dust and stains with clean water in the washing tank 4, drain the water and load it into the running trolley In the net cage 5, send it into the box dryer 6 to continue to remove the remaining water by heating to accelerate the water distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com