Sewing machine

A sewing machine and mechanical structure technology, applied in sewing machine components, sewing equipment, sewing machine control devices, etc., can solve the problems of unsatisfactory dynamic performance, inconvenient motor control, complex mechanical structure, etc., to achieve convenient control, high switching frequency, The effect of compact space layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to better understand the technical principle and working process of the embodiments of the present invention, the present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

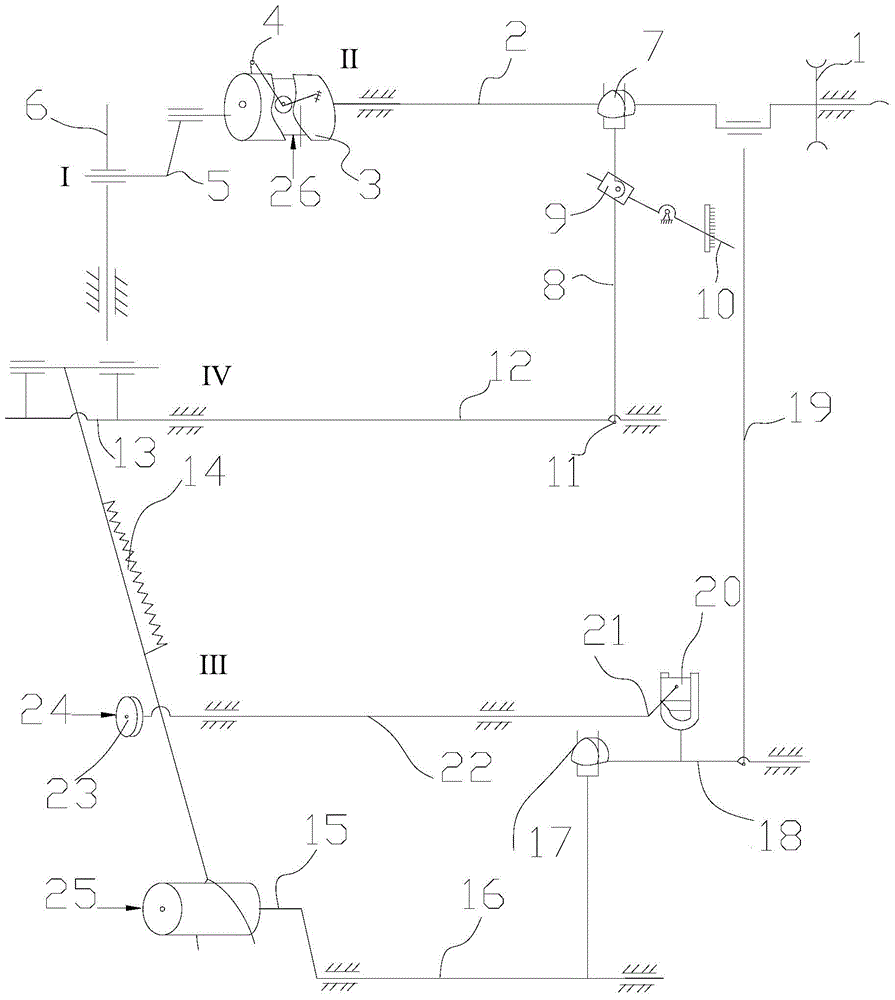

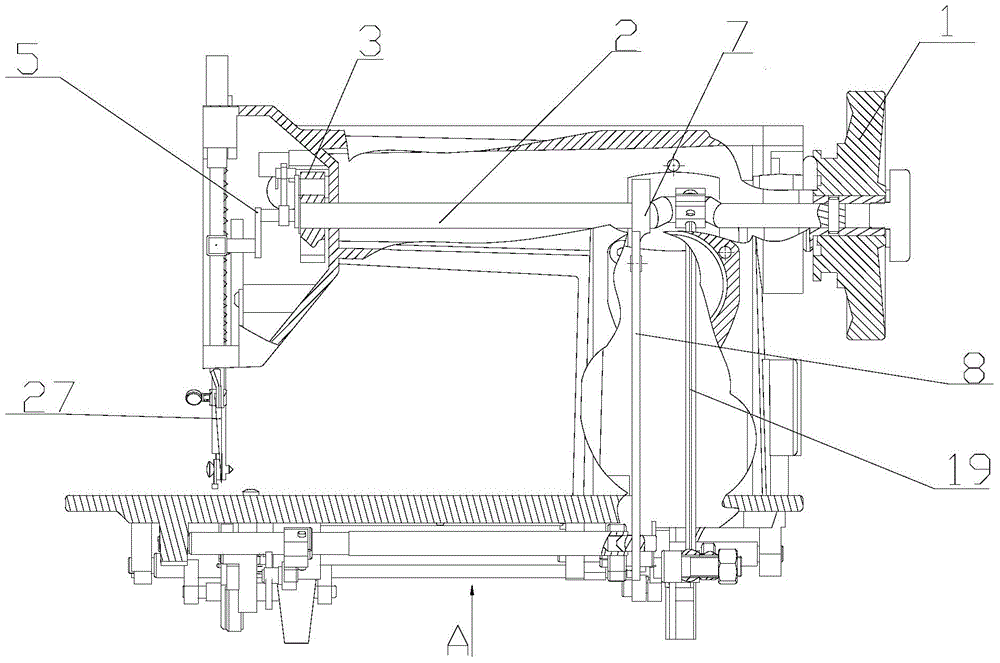

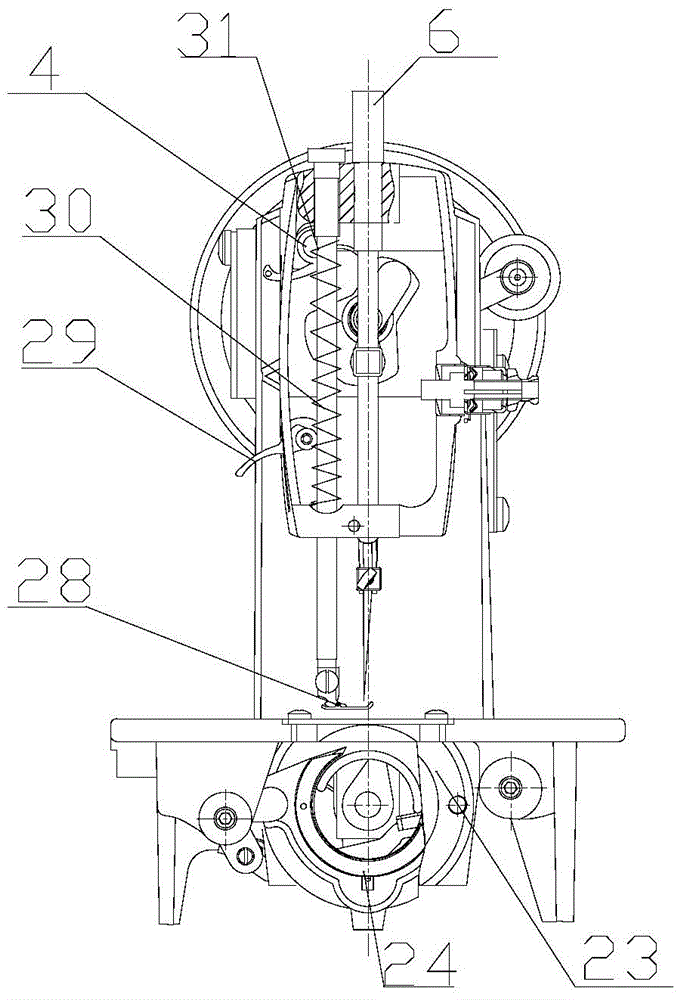

[0026] see also Figure 1-Figure 8 , shows the structure of the main mechanisms and components of the sewing machine of the present invention, and will be described in detail below.

[0027] Such as Figure 1-Figure 5 As shown, the sewing machine of the present invention includes a lead thread mechanism I, a thread take-up mechanism II, a thread hook mechanism III and a cloth feeding mechanism IV, and each mechanism shares some parts, wherein the common upper wheel 1 and the upper shaft 2 transmit power from the motor.

[0028] The wire lead mechanism 1 includes components such as an upper wheel 1, an upper shaft 2, a thread take-up cam 3, a small connecting rod 5 and a needle bar 6: the upper shaft 2 is connected to the upper wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com