Automatic warehouse and method thereof for storing and tacking goods

A technology for automated warehouses and warehouses, which is applied to automated warehouses and the field of accessing goods, can solve the problems of low space utilization of stacker warehouses and AGV warehouses, and achieve the effect of improving space utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

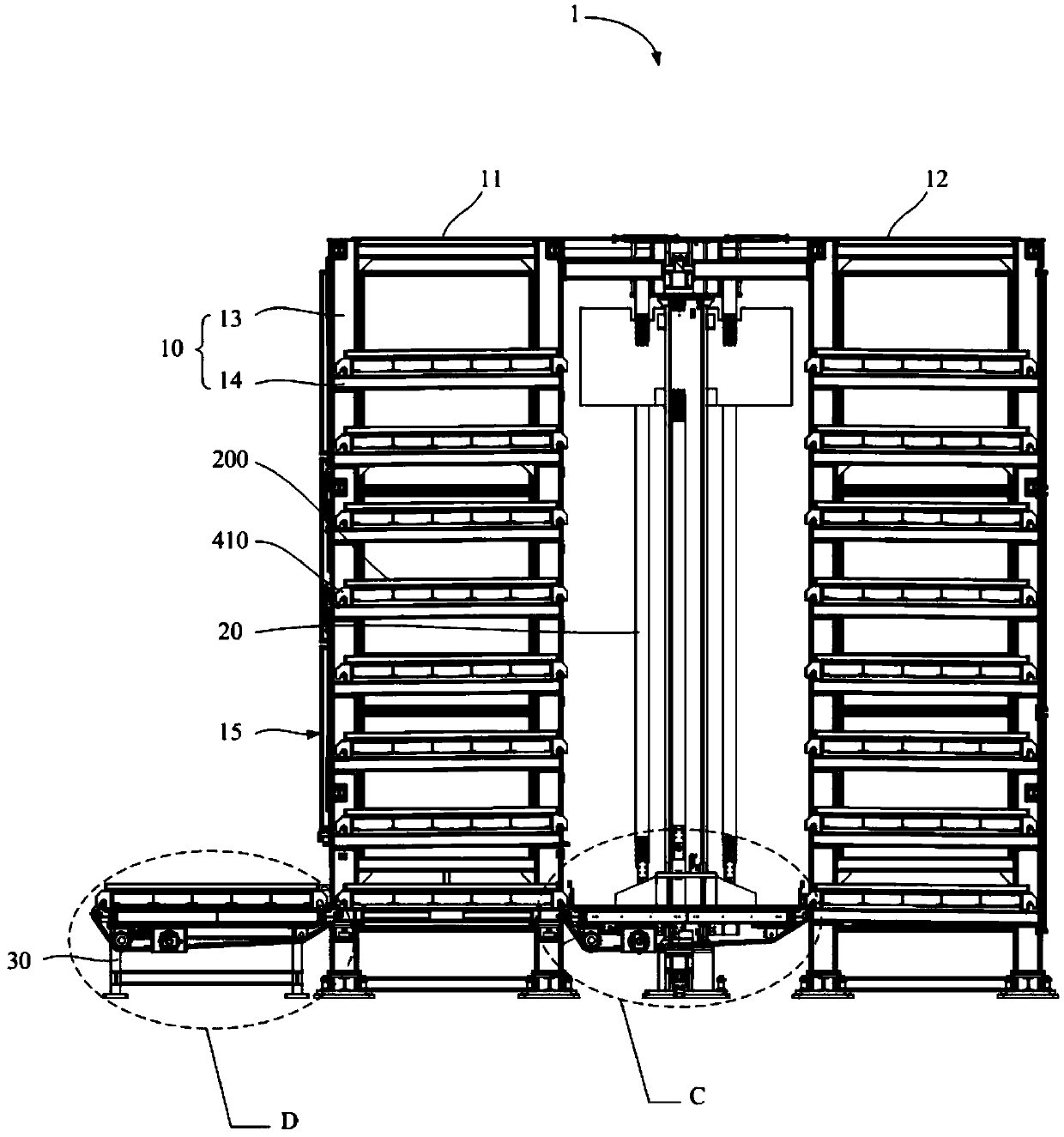

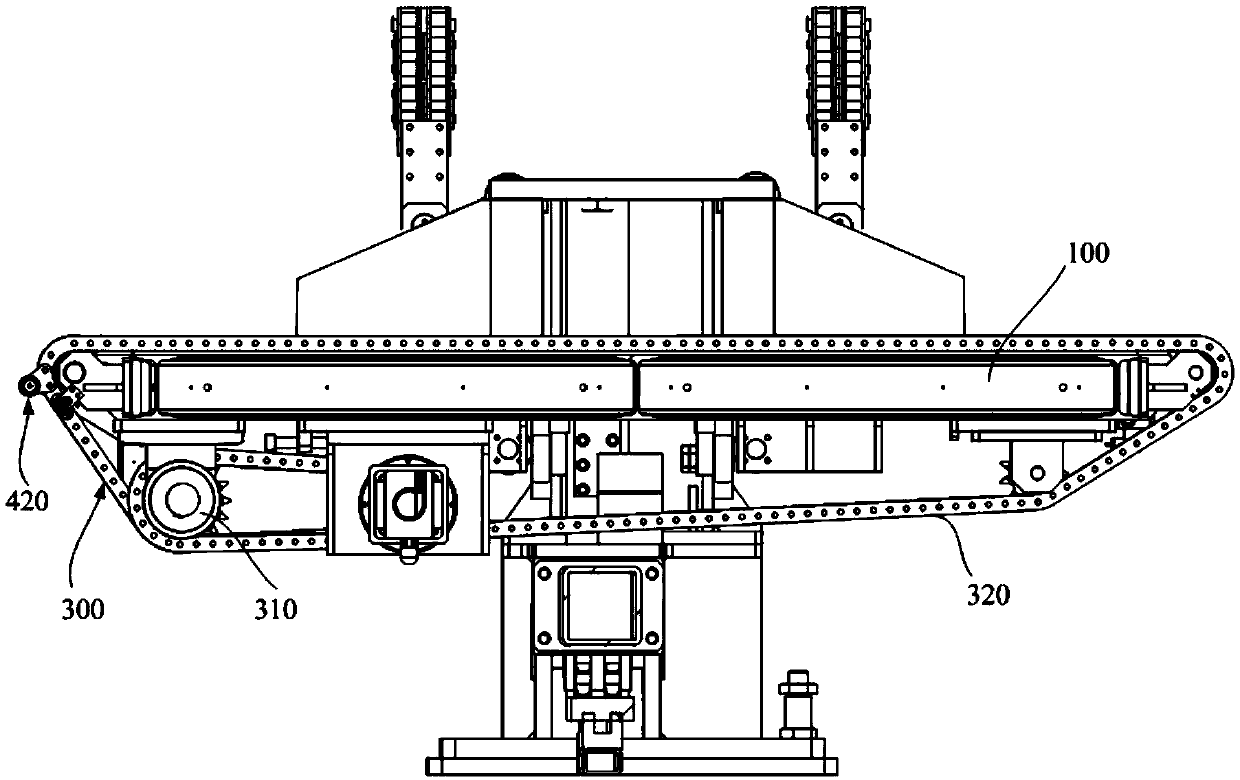

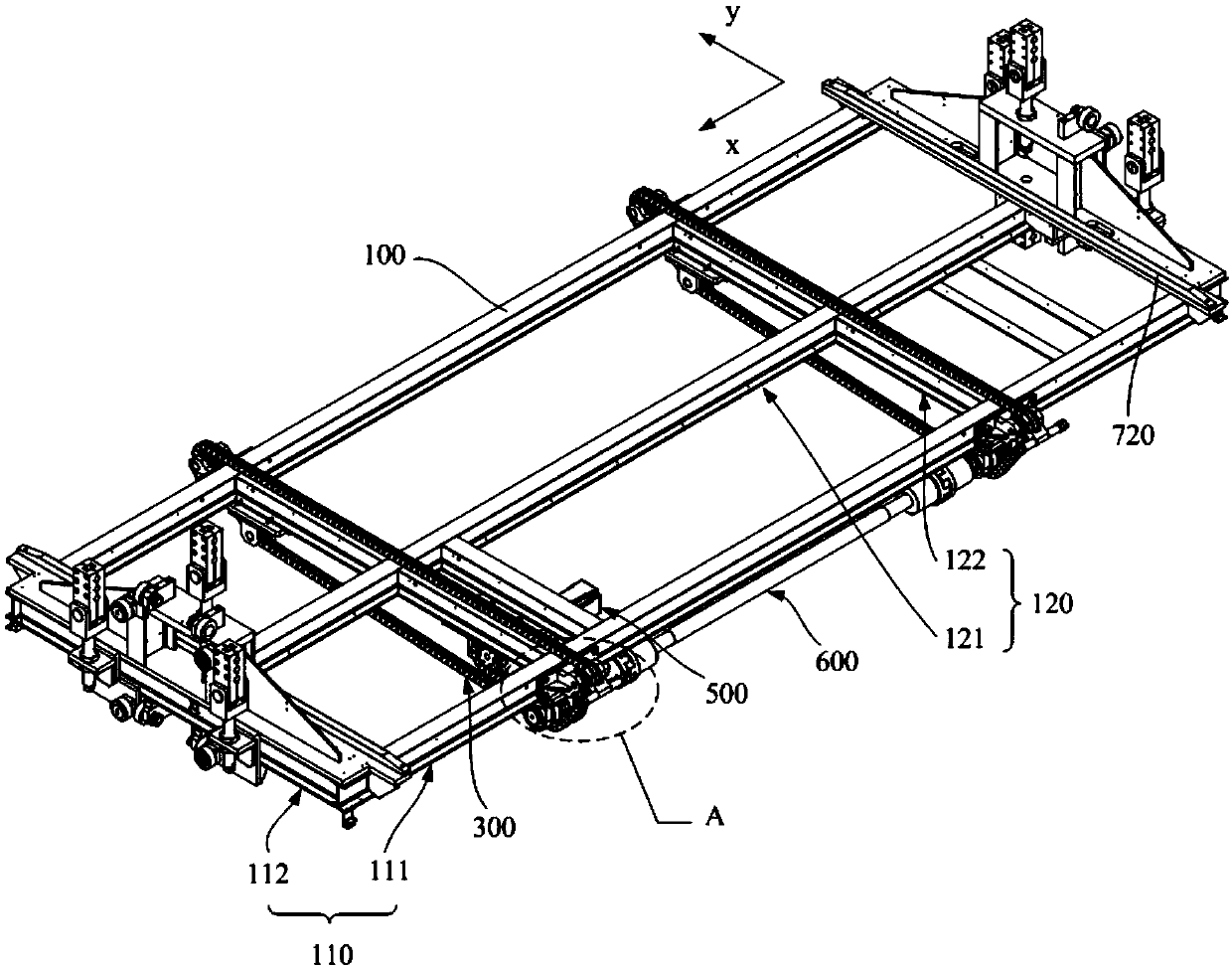

[0041] refer to figure 1 and figure 2 , an automated warehouse 1, comprising: a main loading rack 100, a pallet 200, a main traction member 300, a main hook picker, a storage body 10 and a lifting device 20; wherein, the storage body 10 is provided with a multi-layer shelf 14; The pallet 200 is located on the shelf 14; the lifting device 20 is located on one side of the storage body 10; the main cargo rack 100 is located on the lifting device 20; the main traction member 300 is annular , sleeved on the main cargo rack 100; the main hook extractor includes a hook 410 and a main connecting column 420, the main connecting column 420 is fixedly connected with the main traction member 300, and the hook 410 is fixed It is arranged on the side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com