Full-automatic automobile side wall conveying system with high positioning precision

A positioning accuracy and conveying system technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems affecting the production efficiency of the main welding line, slow operation of electric hoists, and low conveying efficiency, so as to reduce the running time and floor space, system operation is accurate and reliable, and the effect of increasing production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

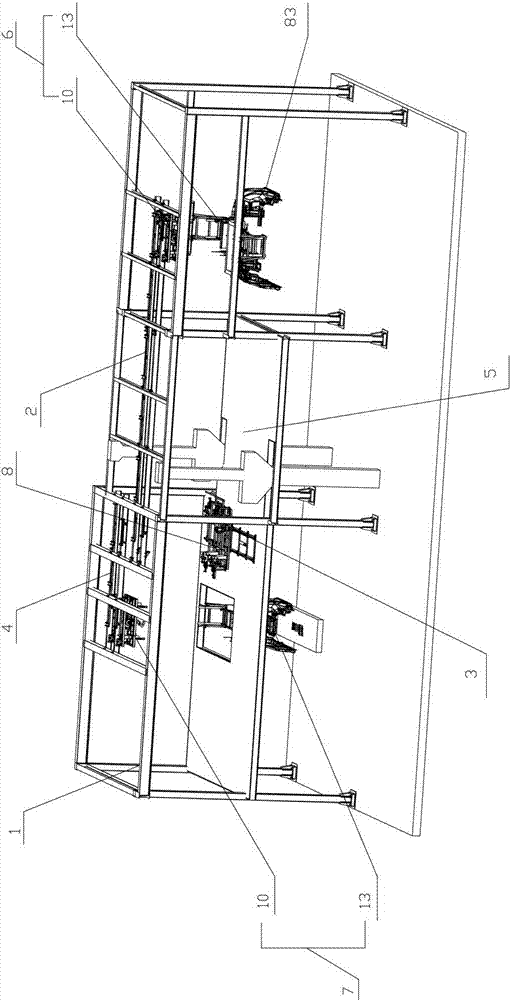

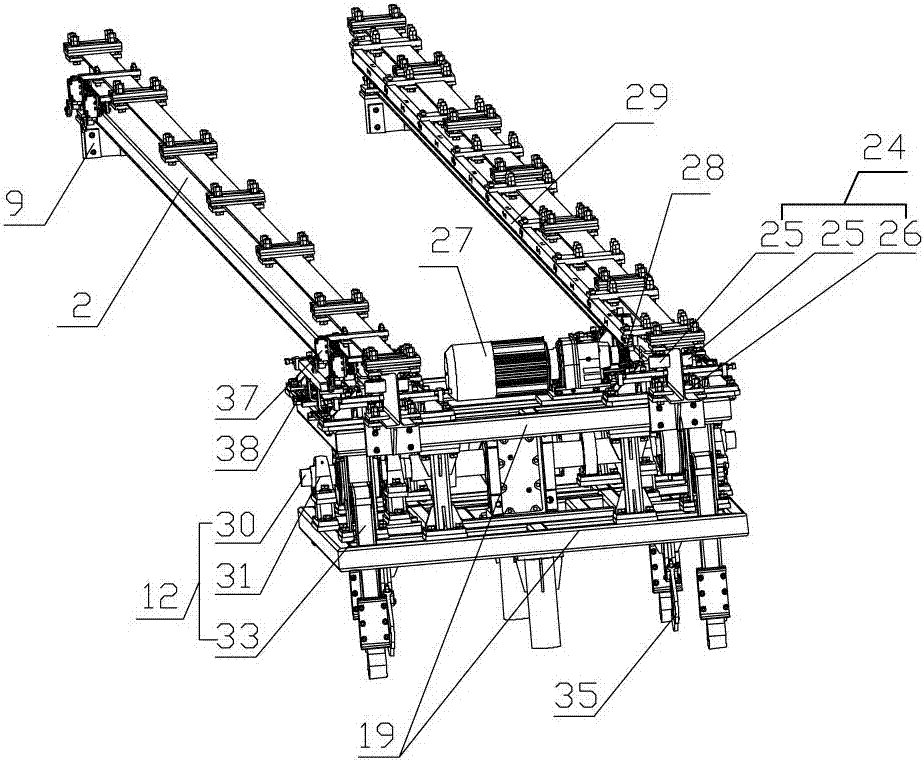

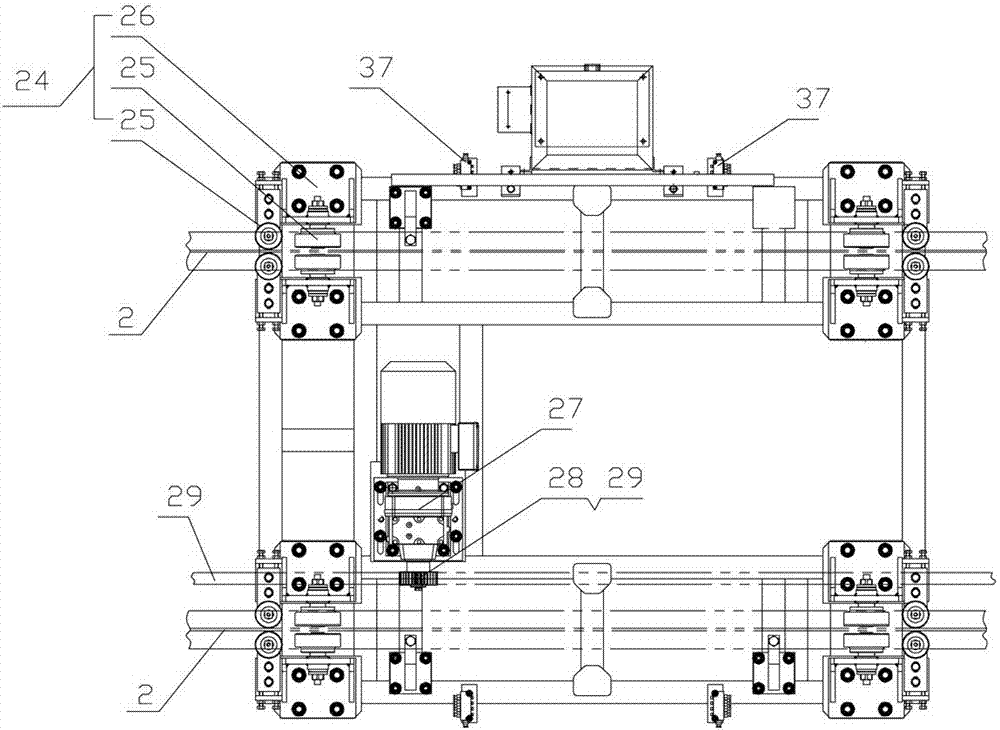

[0045] In this embodiment, a fully automatic automobile side wall conveying system with high positioning accuracy has a steel structure frame 1, and the upper piece track 2, the connecting piece track 3 and the lower piece track 4 are respectively installed in the steel structure frame 1, A horizontally arranged auxiliary beam layer 5 is provided in the steel structure frame 1, the upper track 2 and the lower track 4 are arranged on the top of the steel structure frame 1, and the connecting track 3 is arranged on the auxiliary beam layer 5, wherein the upper The track 2 and the lower track 4 are arranged parallel to each other, the connecting track 3 is vertically arranged with the upper track 2 and the lower track 4, the upper trolley 6 is hoisted on the upper track 2, and the lower track 4 is hoisted Dolly 7, the connecting piece trolley 8 that is connected with the upper piece trolley 6 and the lower piece trolley 7 is installed on the connecting piece track 3; Block buffer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com