Vacuum-sucking paper feeding mechanism for offset press

A paper feeding mechanism and vacuum suction technology, applied in the direction of printing machines, printing, general parts of printing machinery, etc., can solve the problems of damage to paper feeding, cumbersome operation, and uneven ink thickness on the printing surface, and achieve convenient adjustment and smooth operation. Precise and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

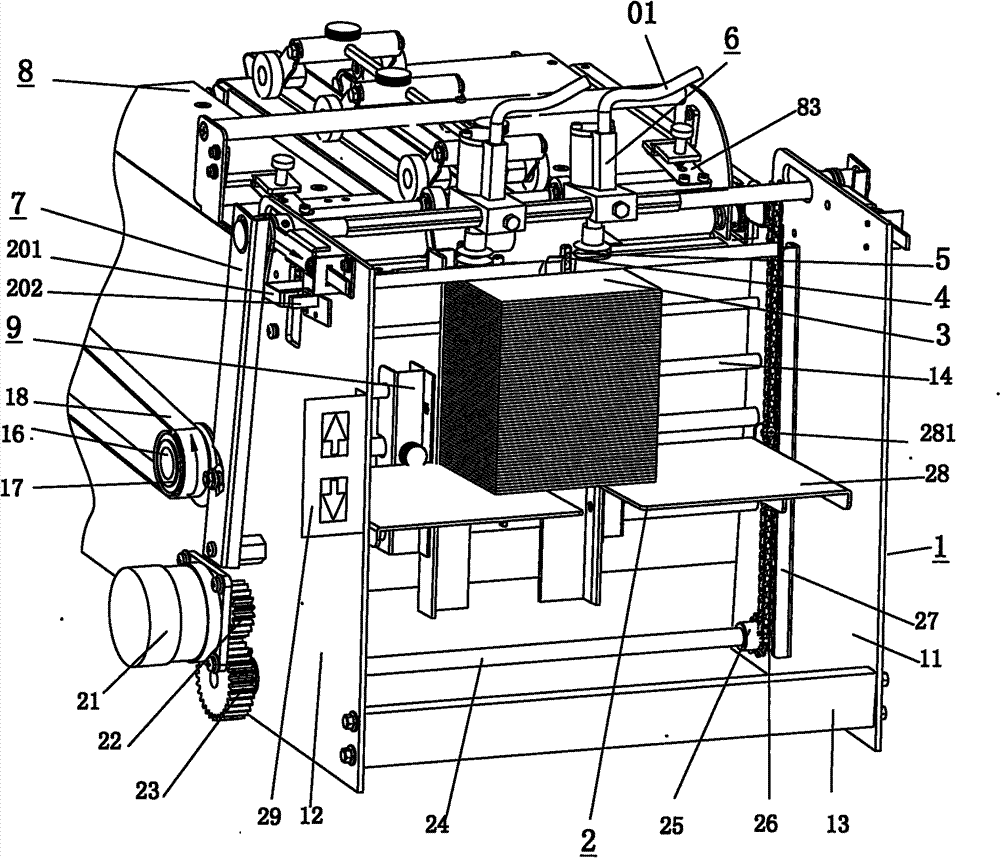

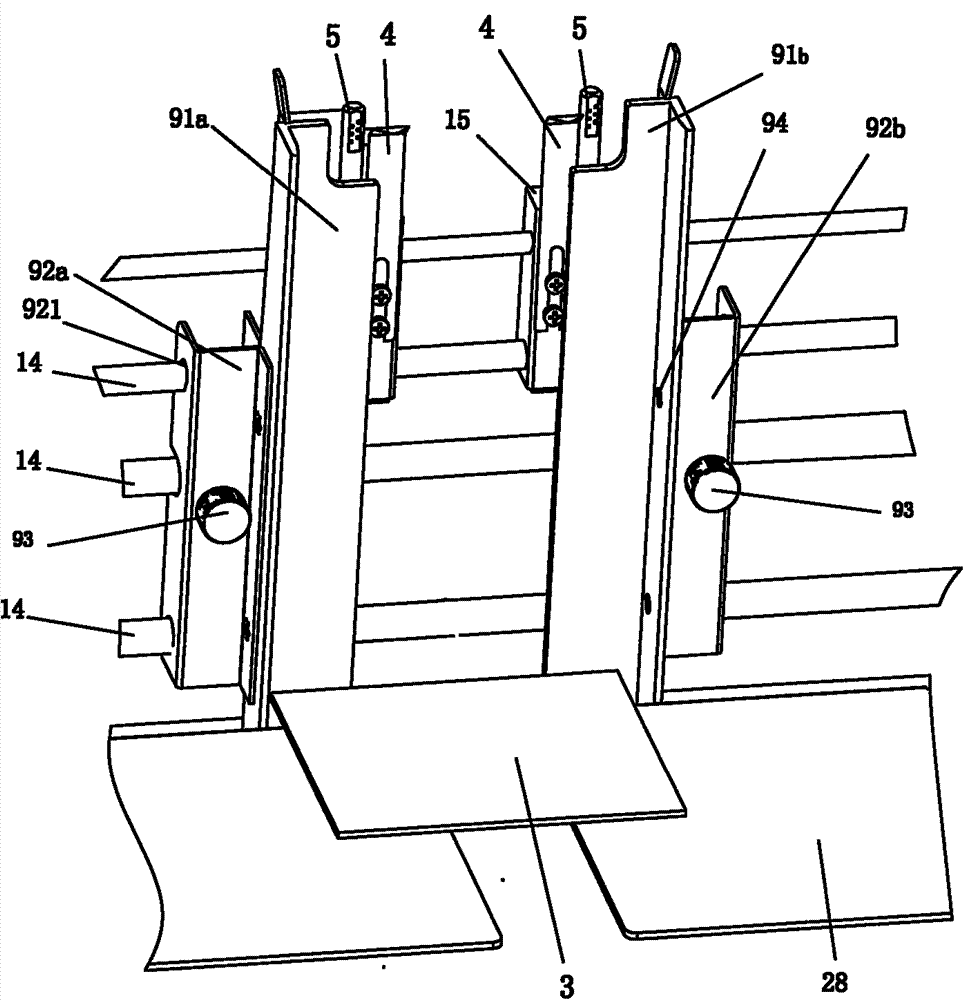

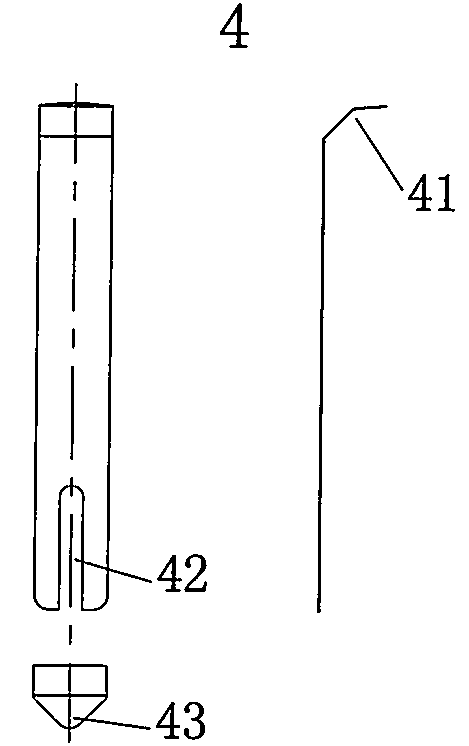

[0024] Example: such as figure 1As shown, a vacuum suction paper feeding mechanism for an offset printing machine includes: a frame 1, the frame is provided with a left side plate 11, a left side plate 12, a front stopper 13, four rear support shafts 14, a linkage shaft 16. Two transmission cams 17 and a transmission belt 18 are formed. The connecting shaft 16 passes through the left side plate 11 and the left side plate 12, and a transmission cam 17 is respectively fixed at the left and right ends. Automatic lifting stacking table 2, described automatic lifting stacking table 2 is provided with the motor 21 that is installed on the left side board 12 outsides, and driving gear 22 is fixed on the output shaft of motor 21, meshes transmission gear 23, and the drive shaft 24 The left end passes through the left side plate 12 and is pressed into and fixed with the meshing transmission gear 23. The left and right sides of the transmission shaft 24 are provided with sprockets 25, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com