Automatic oil spraying device for aerated brick die vehicle

A technology of oil injection device and mold car, which is applied in the direction of injection device, climate sustainability, sustainable waste treatment, etc. It can solve the problems of low efficiency of manual application, uneven application of release oil, unsafe upper and lower mold vehicles, etc. , to achieve the effect of reducing instability, convenient control and operation, and reducing the number of laborers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

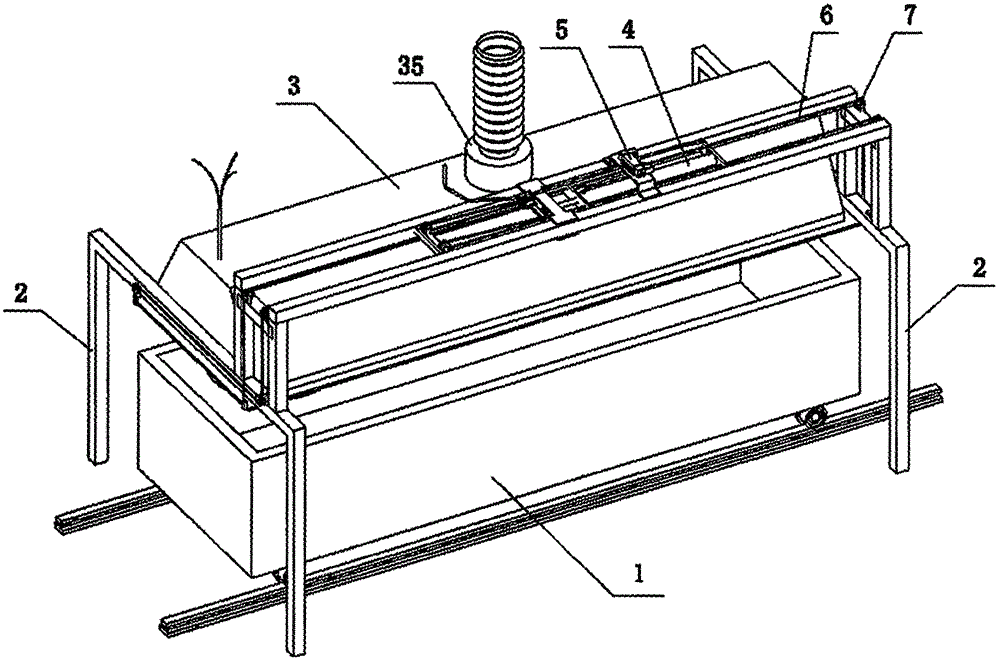

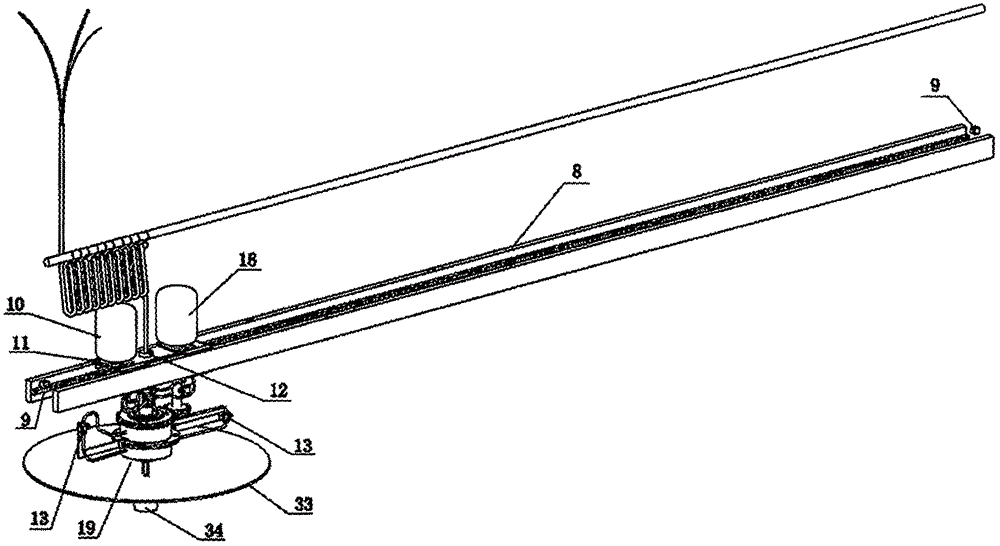

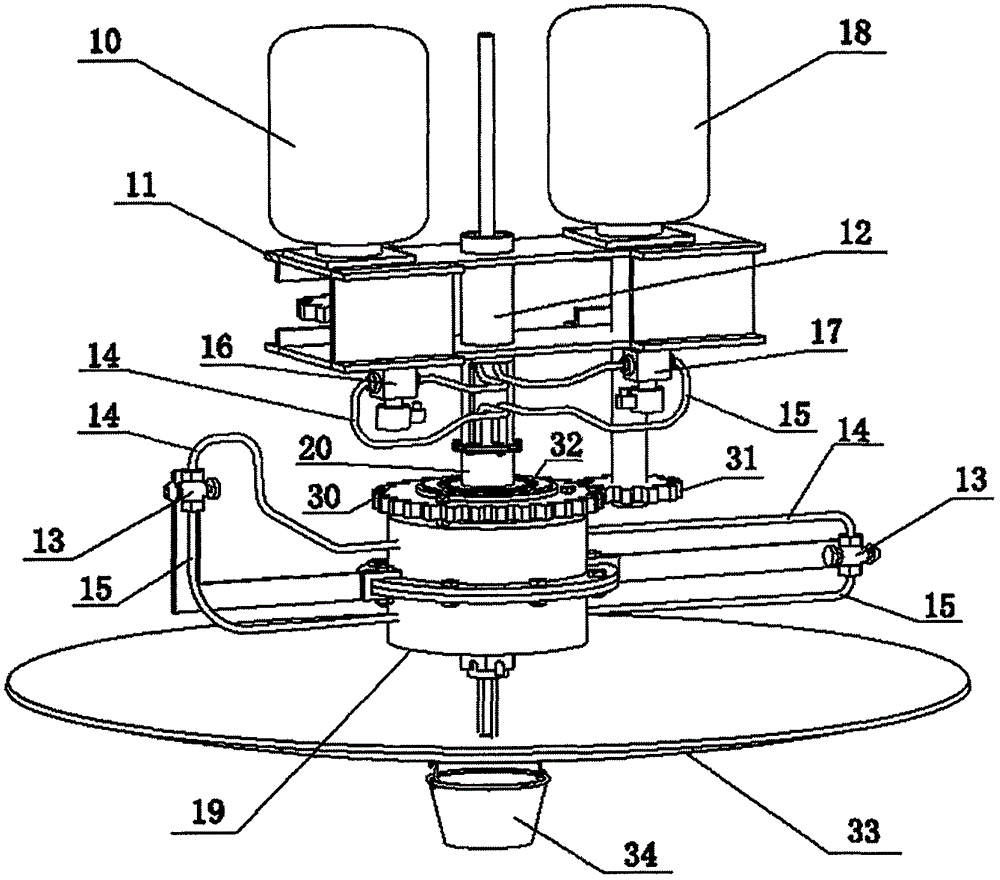

[0024] Such as Figure 1 to Figure 4 As shown, an automatic fuel injection device for an aerated brick mold vehicle, which includes a fuel injection frame 2 erected above the rail of the mold vehicle 1, a fuel injection cover 3 hoisted on the fuel injection frame by a lifting mechanism, and the lower part of the fuel injection cover 3 The fuel injection mechanism is provided, and the lifting mechanism includes a two-way cylinder 4 installed on the fuel injection frame. The two-way cylinder 4 communicates with the air source through the air source hose and the electromagnetic reversing valve 5. A steel wire rope 6, four steel wire ropes 6 are hoisted and connected to the fuel injection cover 3 through the pulley 7; Driven by the reciprocating motor 10, the fuel injection trolley 11 reciprocatingly translates along the slide rail 8. The fuel injection trolley 11 is pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com