Intelligent deviation adjusting type artificial board longitudinal and transverse edge trimming production line and method

A deflection-adjusting, wood-based panel technology, which is applied to circular saws, adjusting equipment, manufacturing tools, etc., can solve the problems of low processing speed, low degree of automation, and easy generation of waste products, so as to improve cutting quality, increase utilization rate, reduce The effect of scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

[0026] The invention is a machine vision-based production line and method for vertically and horizontally sawing wood-based panels.

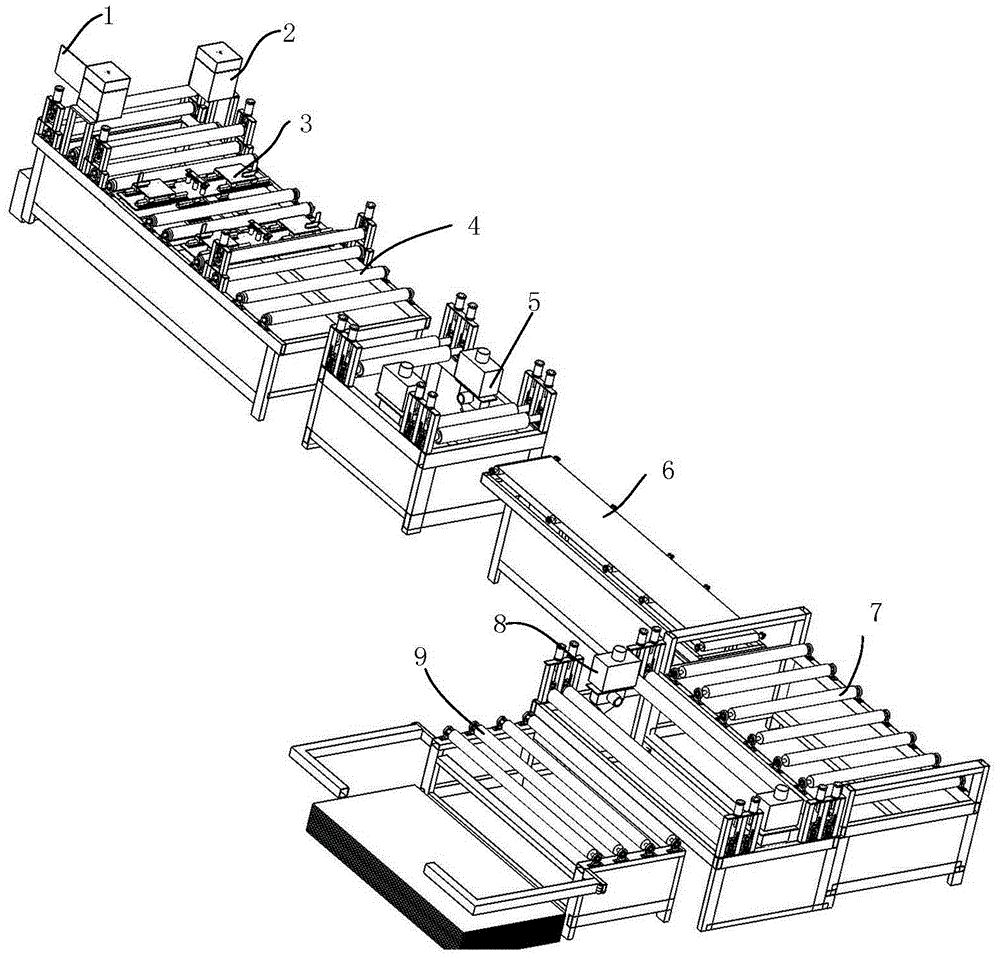

[0027] figure 1 Shown is a schematic front view of the structure of the present invention.

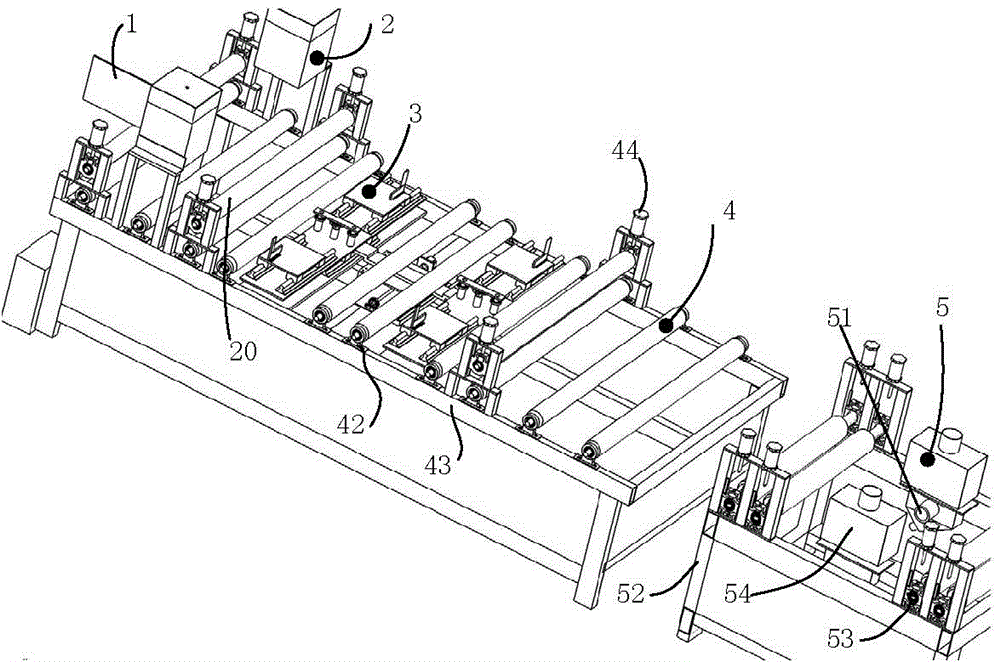

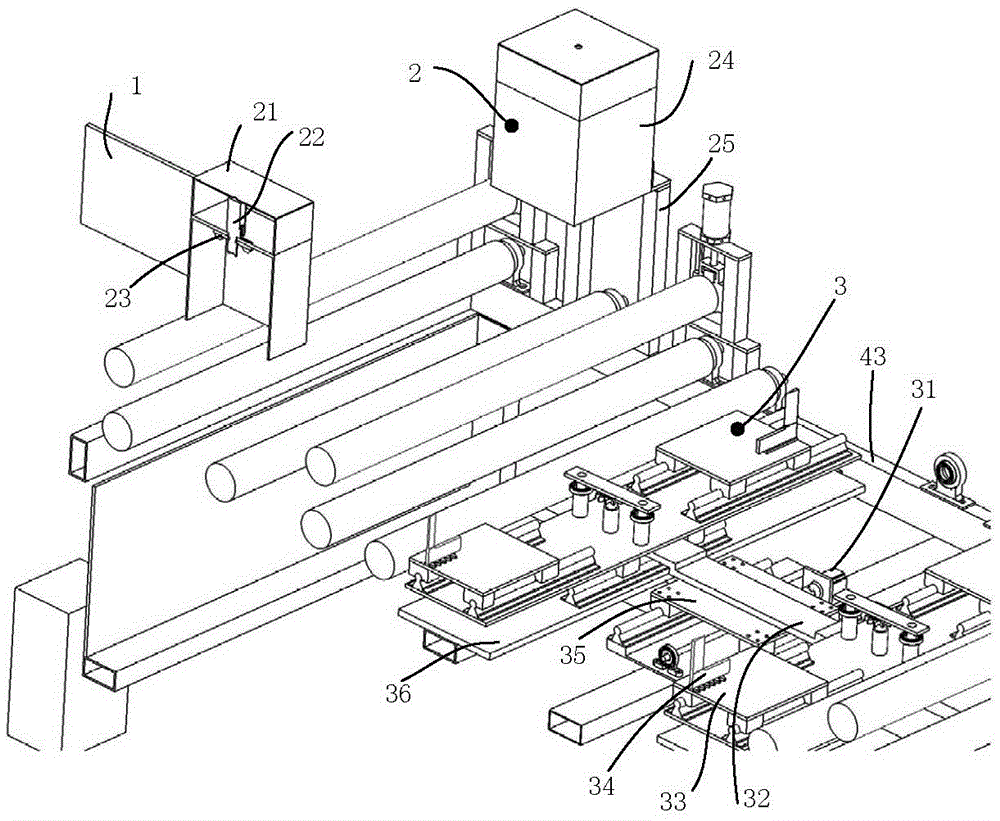

[0028] The present invention includes a plate edge visual recognition system 2, a plate lateral deviation adjustment system 3, a conveying mechanism 4, a plate longitudinal sawing system 5, a conveying mechanism 6, a plate longitudinal centering mechanism 7, a plate transverse sawing system 8, and a stacking mechanism 9 Composition: There are two sets of board edge visual recognition systems 2, which are symmetrically installed above the front end of the conveying mechanism 4; the board lateral deviation adjustment system 3 is installed in the middle of the conveying mechanism 4; the front end of the board longitudinal sawin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com