Feed pre-positioning method and device for molded plate

A front positioning and sheet material technology, applied in feeding devices, wood processing equipment, sawing components, etc., can solve the problems of complex drive structure, low production efficiency, inconvenient debugging, etc., and achieve high positioning and conveying effects and a high degree of automation High, compact process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

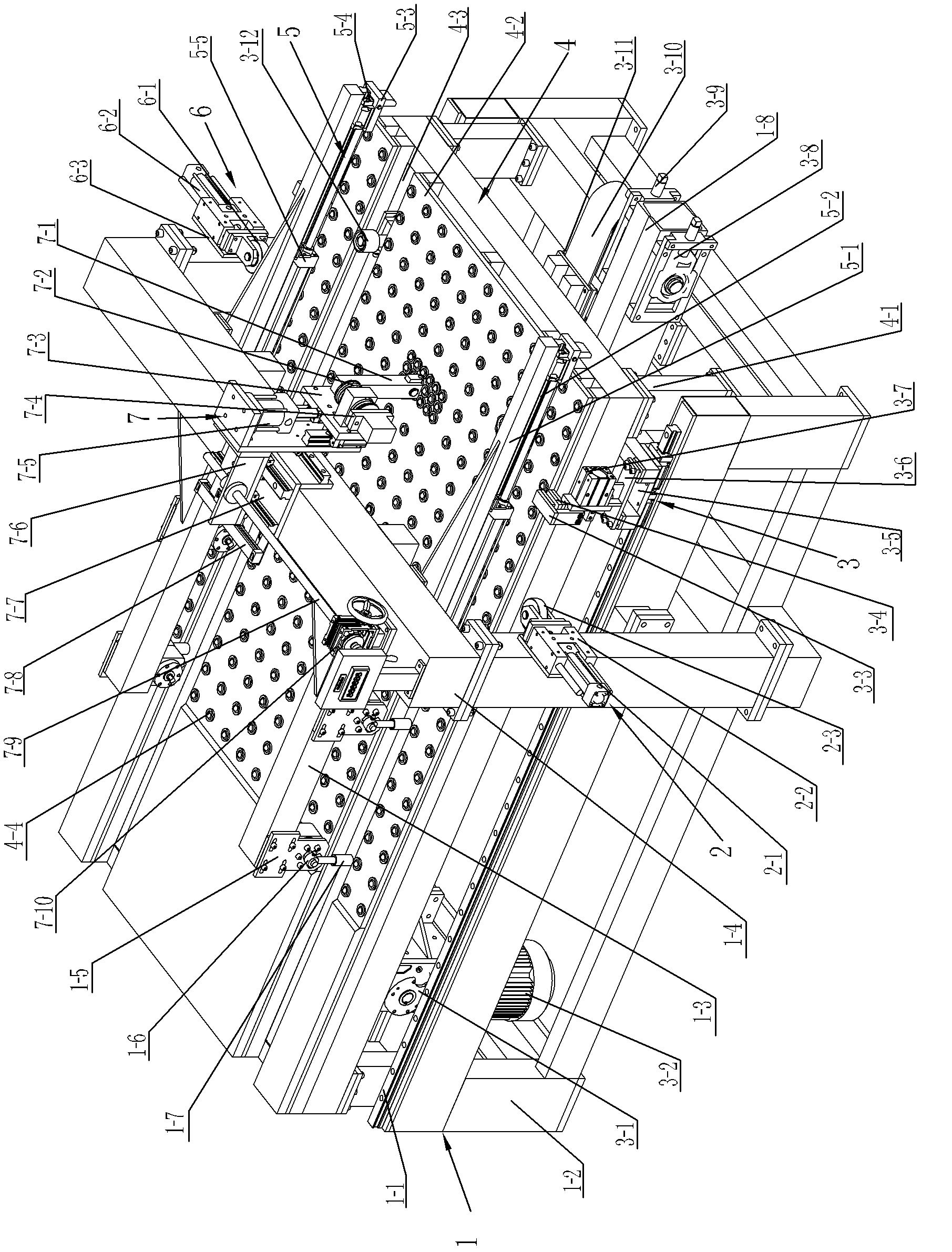

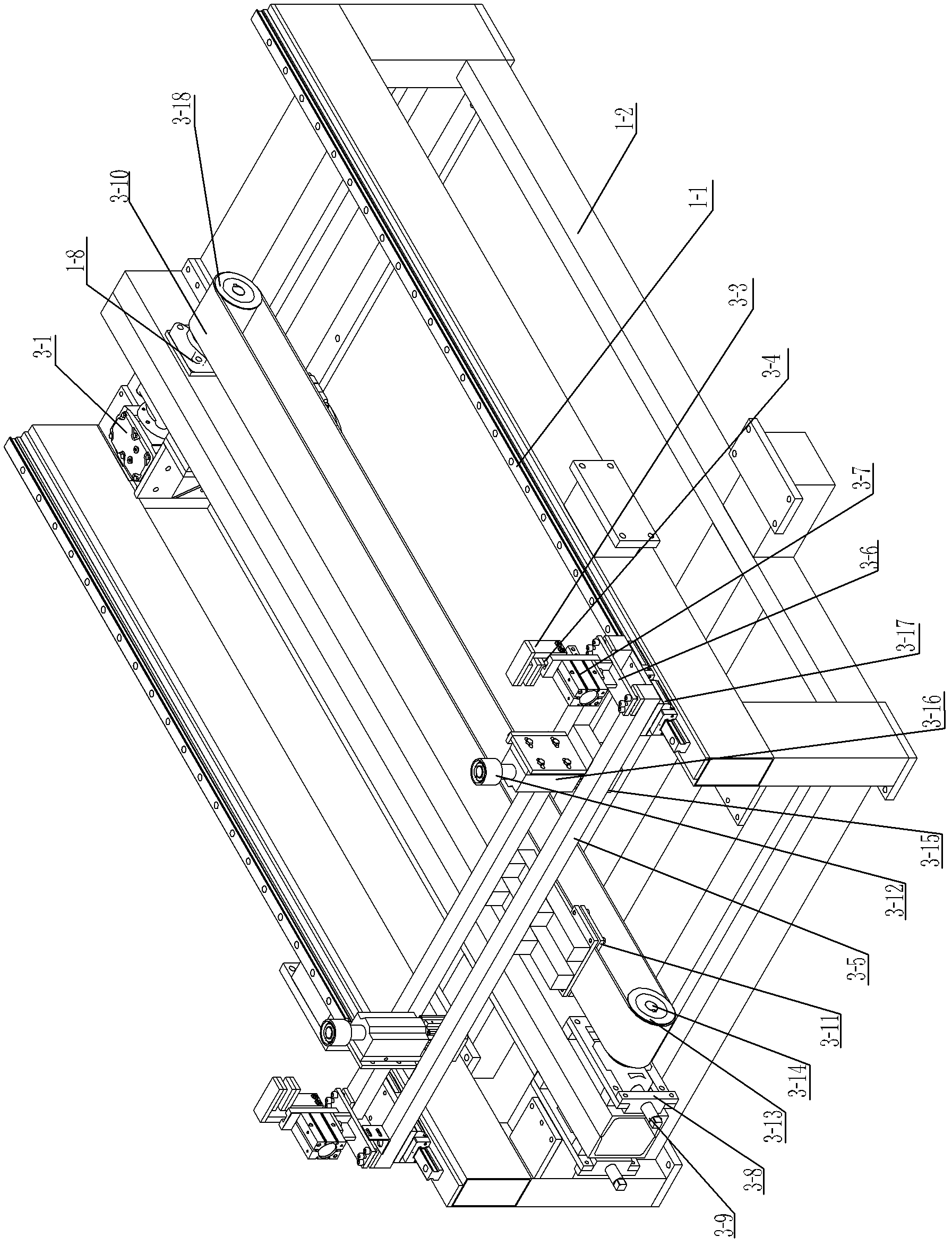

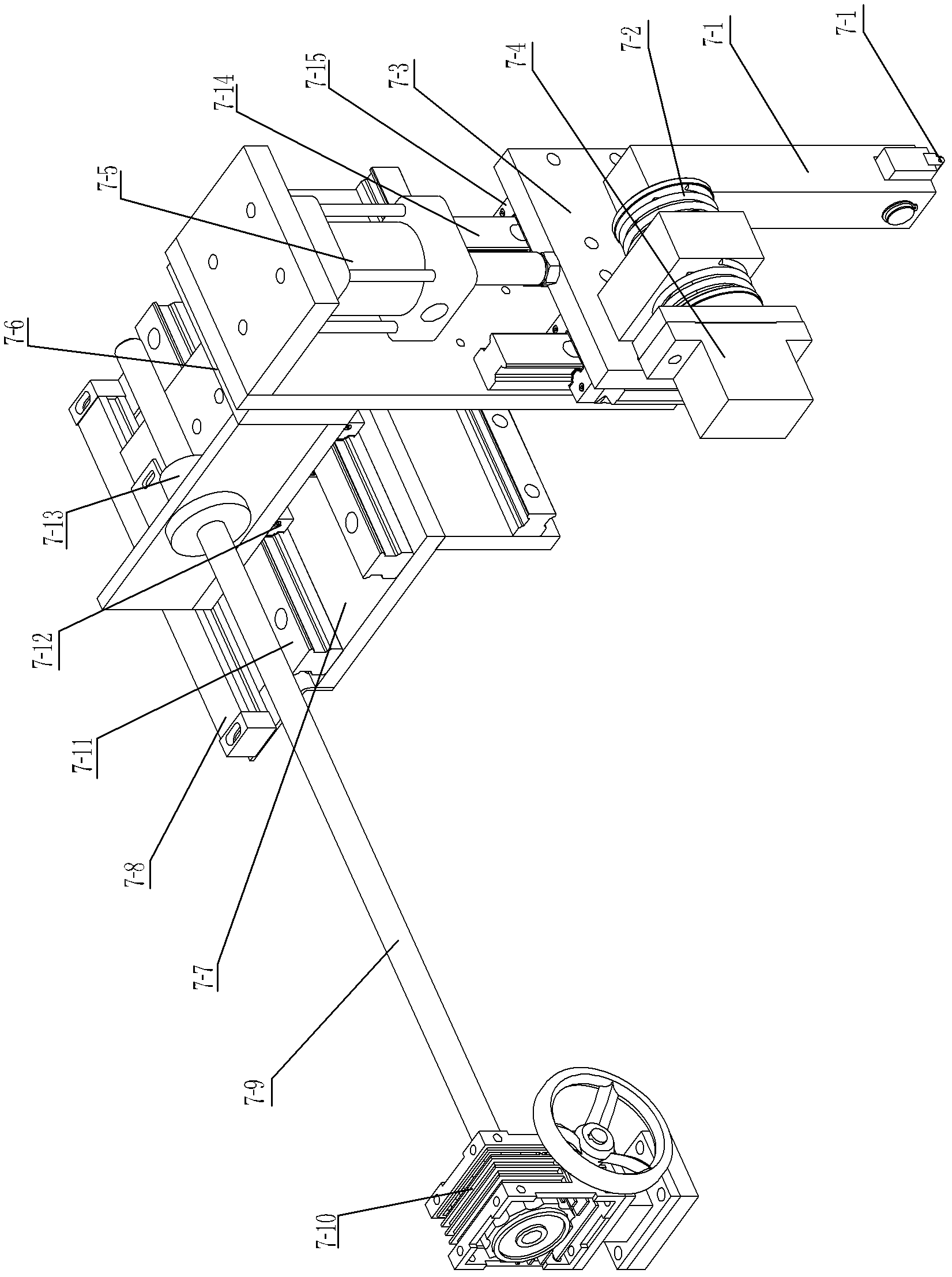

[0028] See Figure 1~3 As shown, the pre-feed positioning method of the molded plate of the present invention is to pull the plate with longitudinal grooves on the surface into the worktable 4-2 with the ball 4-4 through the pull plate 5-3, and by clamping Between the jaws of the cylinder 3-7, when the front surface of the sheet material contacts the two rotating arms 1-7, the rotating arm 1-7 sends out a signal, and the two positioning rings 3-12 stretch out and meet the rear end surface of the sheet material. connected, and under the action of the rotating arm 1-7, the rear end of the plate is connected to the two positioning rings 3-12 to realize the positioning of the rear end of the plate, and the side limiter 2-3 pushes the plate to make the plate The longitudinal groove on the material is located on the side of the positioning roller 7-16 at the bottom of the vibrating arm 7-1, the pull plate 5-3 and the side limiter 2-3 return to their original positions simultaneously...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com