Automatic feeding device and automatic cooking device thereof

A feeding device and cooking equipment technology, applied in cooking utensils, household utensils, applications, etc., can solve problems such as inapplicability, non-environmental protection, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

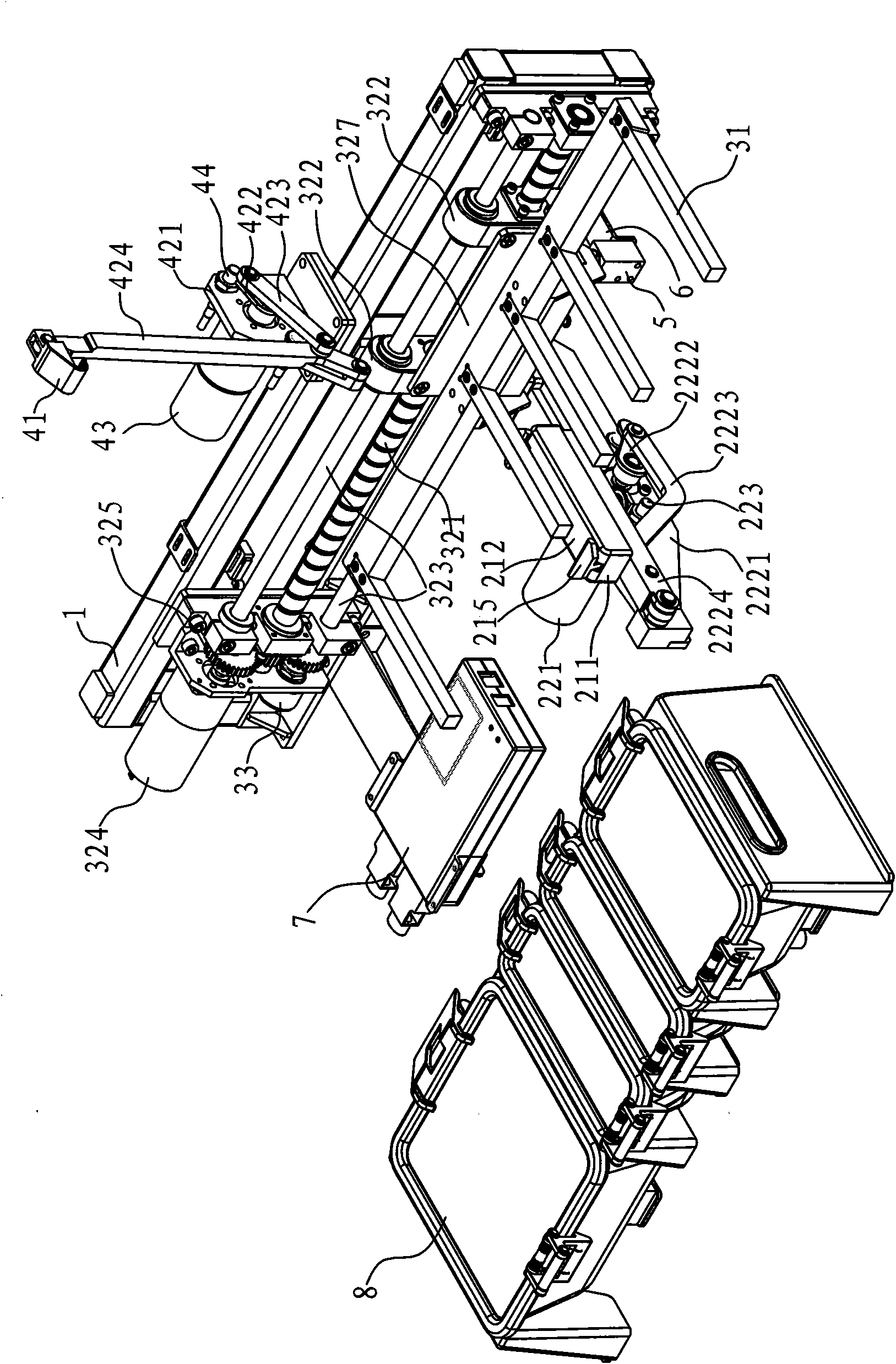

[0049] Please refer to figure 1 As shown, the present invention discloses a feeding device for cooking equipment, which can put the materials in the material box into the cooking equipment according to a predetermined program, which includes a frame body 1, a feeding mechanism 2, and a translation mechanism 3 and open mechanism 4, where:

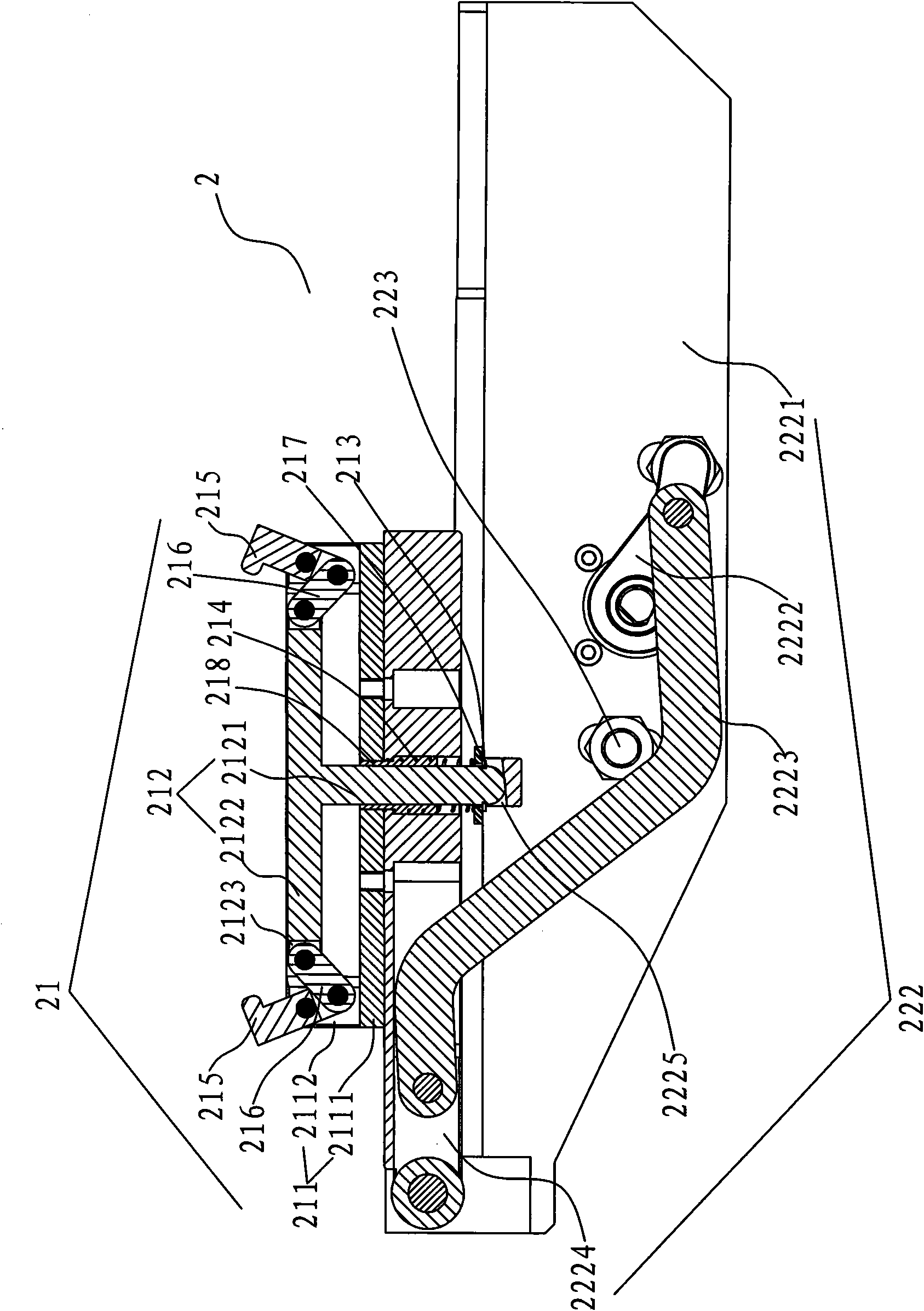

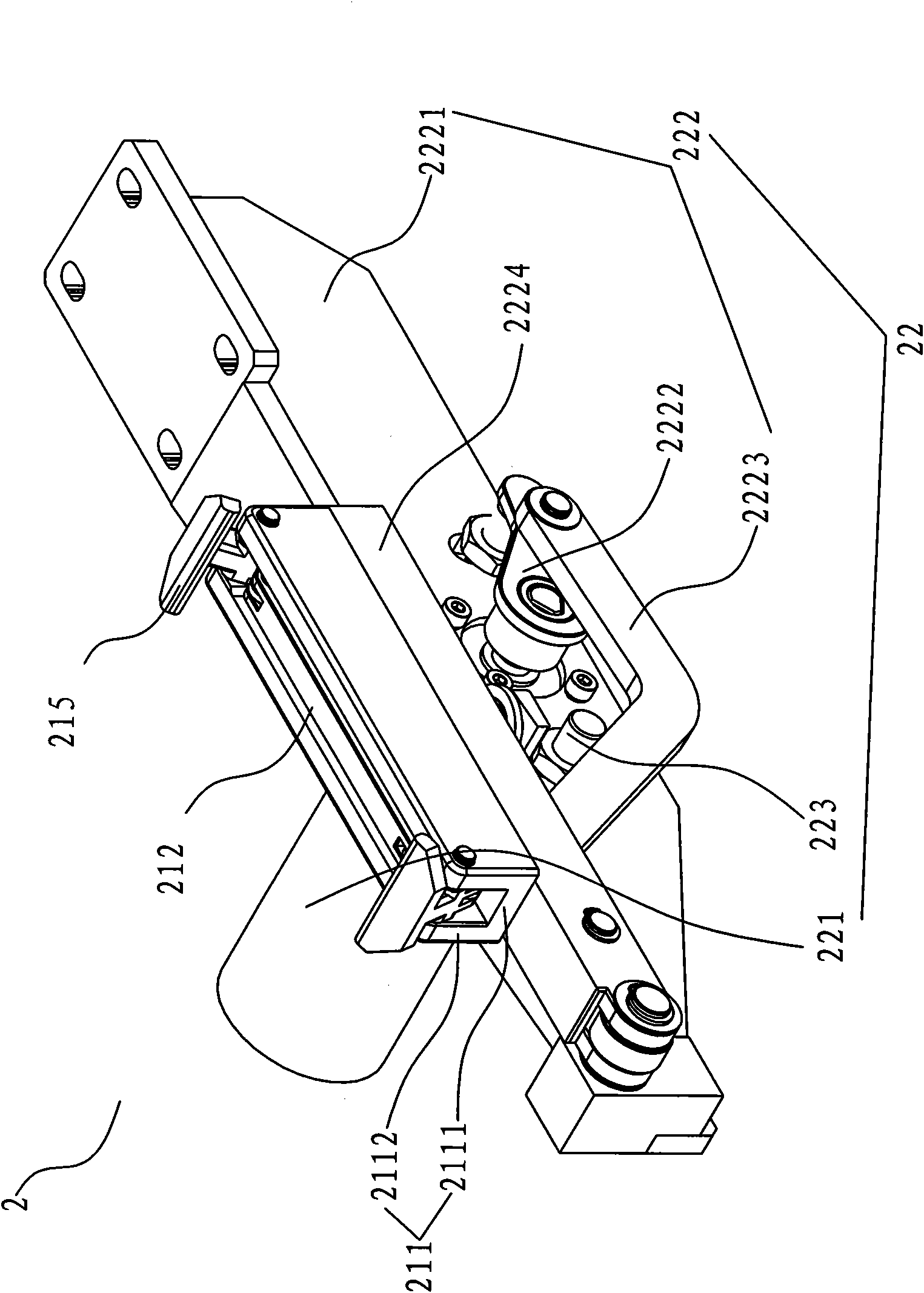

[0050] Cooperate figure 2 , 3 As shown, the feeding mechanism 2 includes a connecting mechanism 21 and a moving mechanism 22 , and the magazine 8 is connected to the moving mechanism 22 through the connecting mechanism 21 .

[0051] The connecting mechanism 21 may include a clamping member with at least two clamping positions and a clamping driving member.

[0052] The clamping driver includes: a base 211, a T-shaped central rod 212, a retaining ring 213 for the shaft, a compression spring 214, and the base 211 includes a base plate 2111 and at least one vertical baffle plate 2112, and the vertical rod 2121 of the T-shaped central rod 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com