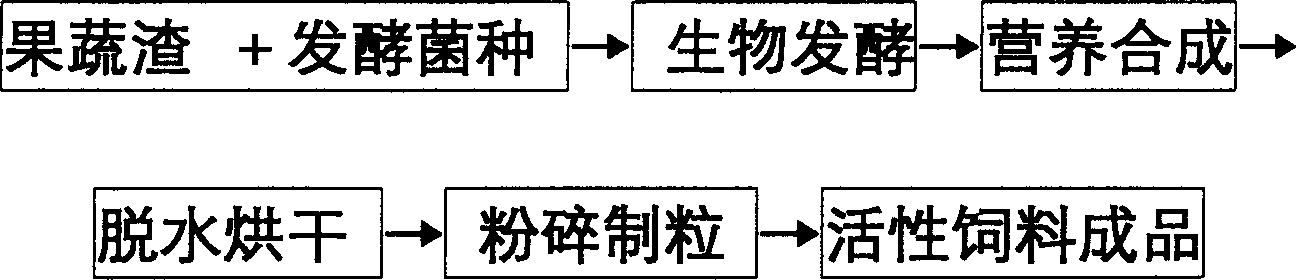

Process of fodder with bioactivity

A production process and biologically active technology, applied in the field of feed processing industry, can solve unclear problems, achieve the effects of increasing vitality, promoting digestion, absorption and utilization, and realizing resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1000kg of fresh apple pomace, add (concentration) 100ml of heat-resistant Kluyveromyces liquid, 500g of calcium carbonate, 500g of soybean protein powder, and carry out solid fermentation under the conditions of pH 5-7 and temperature 25-40°C.

[0033] The fermented apple pomace is heated at about 700°C, dried and dehydrated, crushed (ordinary pulverizer), ultraviolet (5 minutes) sterilized and magnetically inspected to make apple dry pomace.

[0034] Measure the nutritional content of the dried pomace obtained, the results are shown in Table 1

[0035] crude protein

21.97%

9.38%

26mg / kg

0.009mg / kg

crude fat

4.16%

0.42%

iron

8.8×10 2 mg / kg

1.32mg / kg

crude fiber

16.55%

0.10%

26mg / kg

1.05mg / kg

crude ash

2.98%

24mg / kg

2.32×10 2 mg / kg

chrome

...

Embodiment 2

[0042] 1000kg of fresh apple pomace, 300g of Kluyveromyces thermotolerant, 200g of Saccharomyces cerevisiae and 1000g of sodium bicarbonate are added, and aerobic fermentation is carried out under the conditions of pH 5-7 and temperature 25-35°C.

[0043] The fermented apple pomace is heated at about 800°C, dried and dehydrated, crushed (ordinary pulverizer), ultraviolet (5 minutes) sterilized and magnetically inspected to make dry residue.

[0044] The nutritional content of the obtained dried pomace was measured, and the results are shown in Table 2.

[0045] crude protein

20.38%

10.65%

28mg / kg

0.01mg / kg

crude fat

4.42%

0.40%

iron

8.9×10 2 mg / kg

1.31mg / kg

crude fiber

15.45%

0.11%

27mg / kg

1.04mg / kg

crude ash

2.86%

26mg / kg

2.30×10 2 mg / kg

chrome

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com