Tenon workpiece array trail

A track and workpiece technology, which is applied in the field of the entire track of the tenon workpiece, can solve the problems of screening errors, low efficiency, waste production, etc., and achieve the effect of fast feeding speed, simple structure and high screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

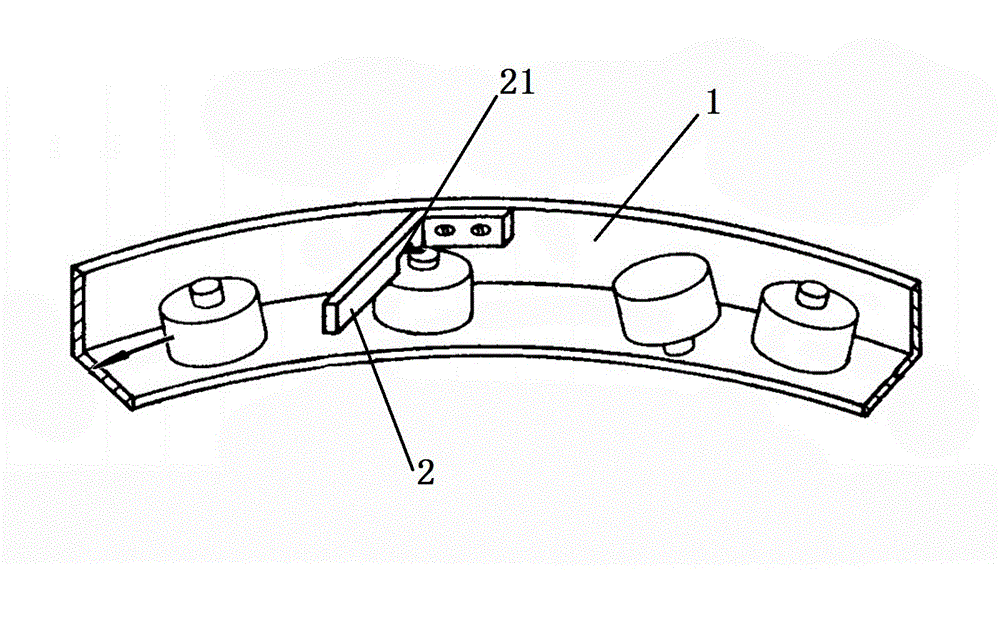

[0010] refer to figure 1 , a tenon workpiece alignment track, including a track 1 horizontally arranged on the wall of the collection basin, the cross section of the track 1 is L-shaped, the horizontal bottom wall of the track 1 is the workpiece support surface, and the vertical side wall of the track 1 is a bolt A horizontal limiting plate 2 is attached. The limiting plate 2 is located above the horizontal support surface and points to the center of the collecting basin, and the limiting plate 2 is provided with a notch 21 matching the tenon of the workpiece.

[0011] When in use, the workpiece is pushed by the initial force to slide on the track 1, and the workpiece with the tenon facing upward can pass through the gap 21 on the limiting plate 2 smoothly and enter the chute, while the workpiece with the tenon facing downward will be blocked by the limiting plate 2 and fall. into the collection basin.

[0012] The above are only preferred embodiments of the present inventio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com