Double-cylinder linear compressor

A linear compressor and cylinder technology, applied in the field of compressors, can solve the problems of high frictional resistance, complex structure, and low efficiency of compressors, and achieve the effects of convenient processing, simple structure, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] specific implementation

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings.

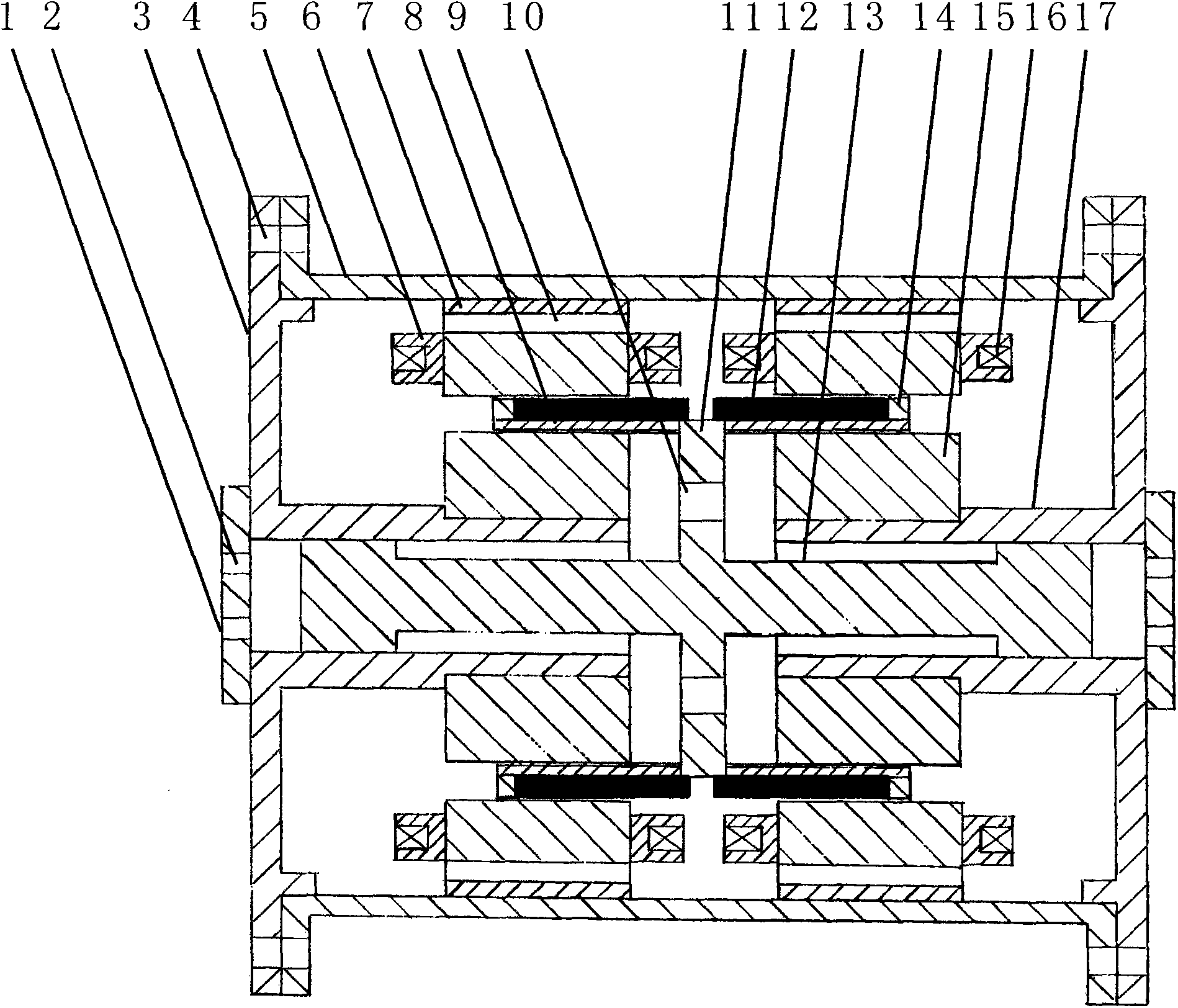

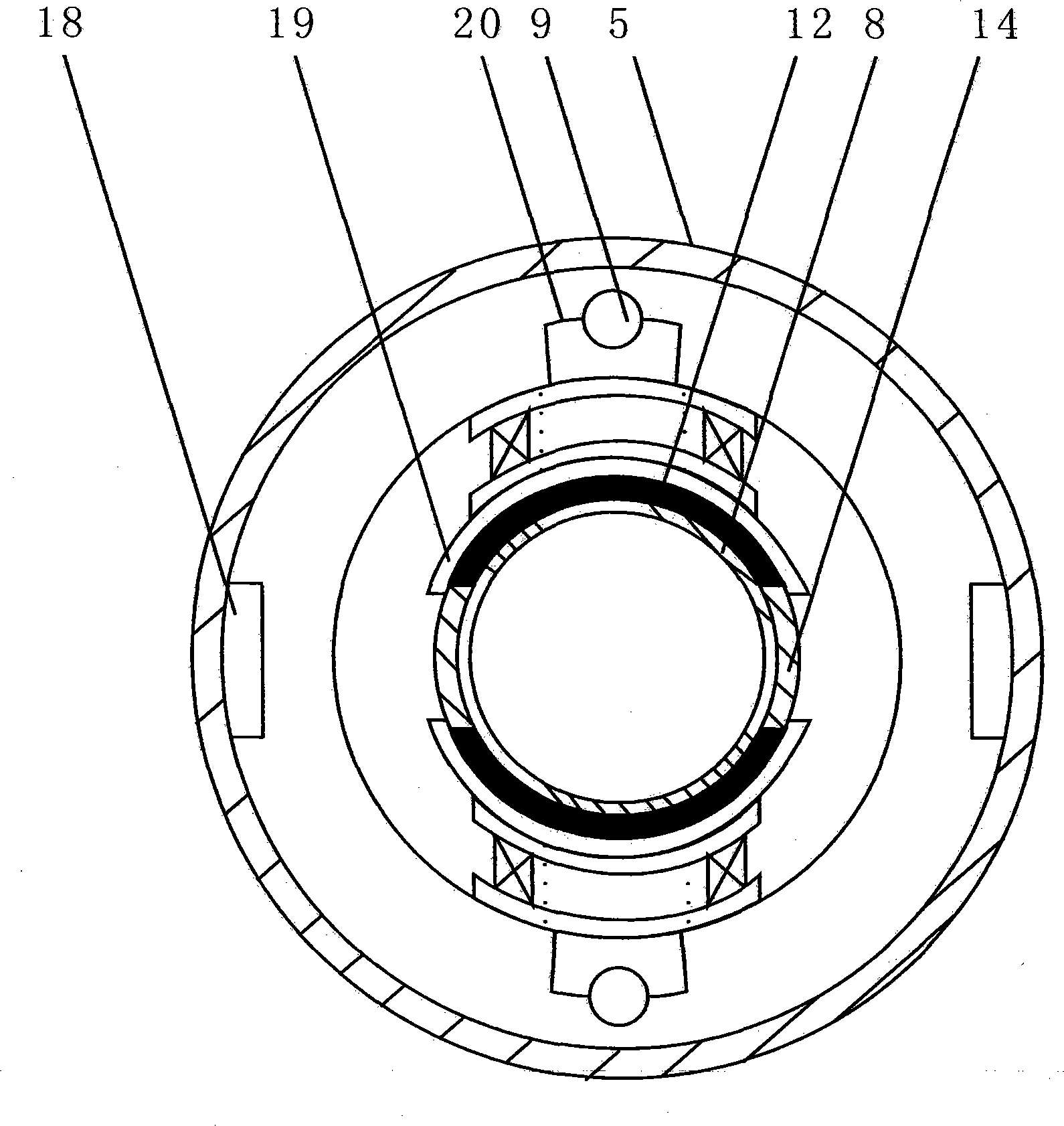

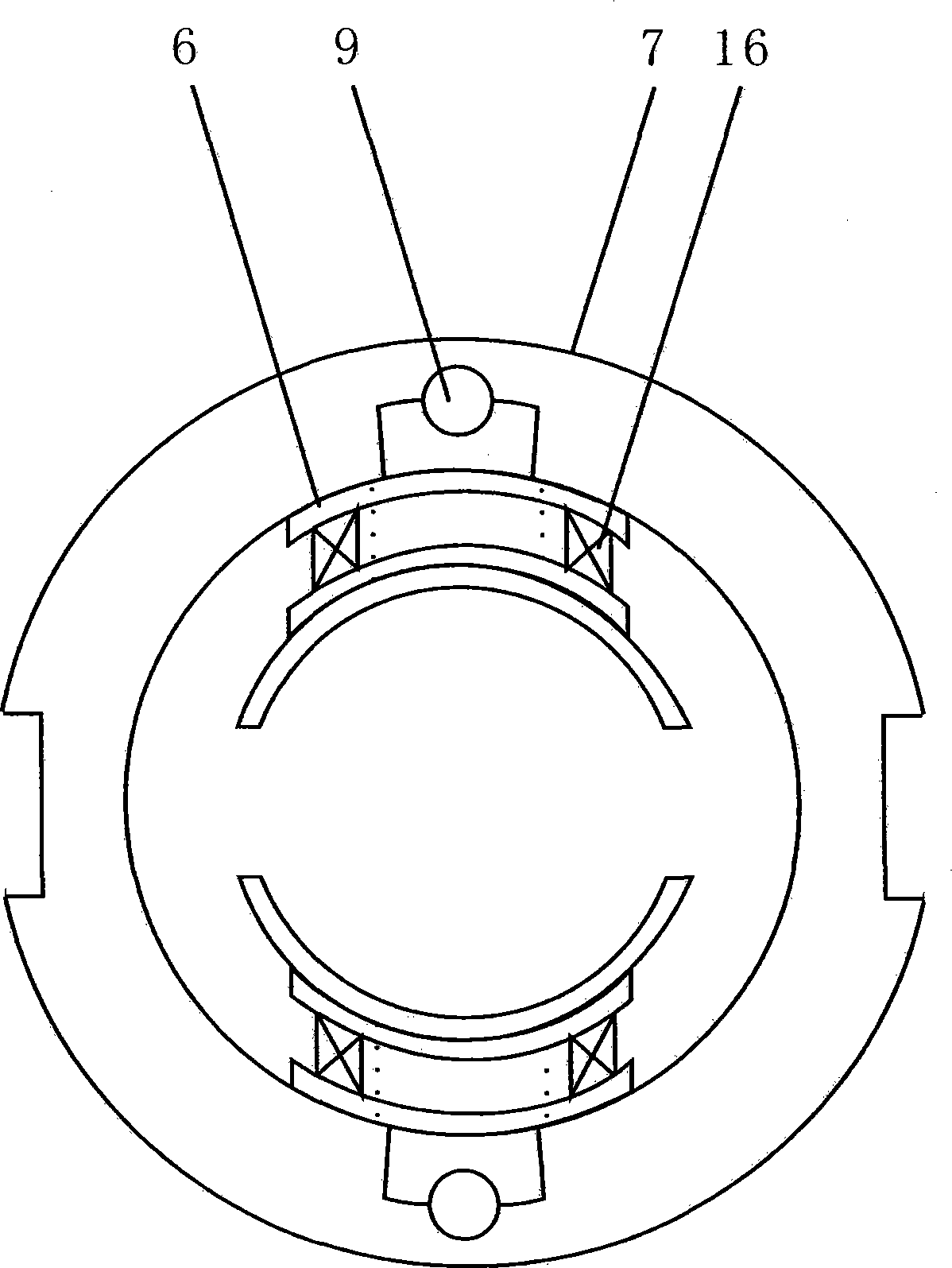

[0014] See attached figure 1 , figure 2 , image 3 , one A two-cylinder linear compressor embodiment, mainly including an intake valve 1, an exhaust valve 2, an end cover 3, an end cover connection hole 4, a casing 5, a coil former 6, an outer stator 7, a bushing 8, and a pole fixing Hole 9, ventilation hole 10, mover support wall 11, permanent magnet 12, piston 13, mover 14, inner stator 15, winding coil 16, cylinder 17, process tank 18, pole palm 19, trapezoidal slot 20, housing 5 Two outer stators 7 are arranged in the inner hole, and the two outer stators 7 are axially arranged. There is a distance between the two outer stators 7 , and a spacer is arranged between the two outer stators 7 to control the distance between the two outer stators 7 through the spacer. The inner stator 15, the outer stator 7 and the pole p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com