Device for automatically recycling building waste slag blocks after crushing

A technology of automatic recycling and waste residue, applied in the direction of grain processing, etc., can solve the problems of large space occupation, inability to use directly, large slag blocks, etc., and achieve good recycling effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

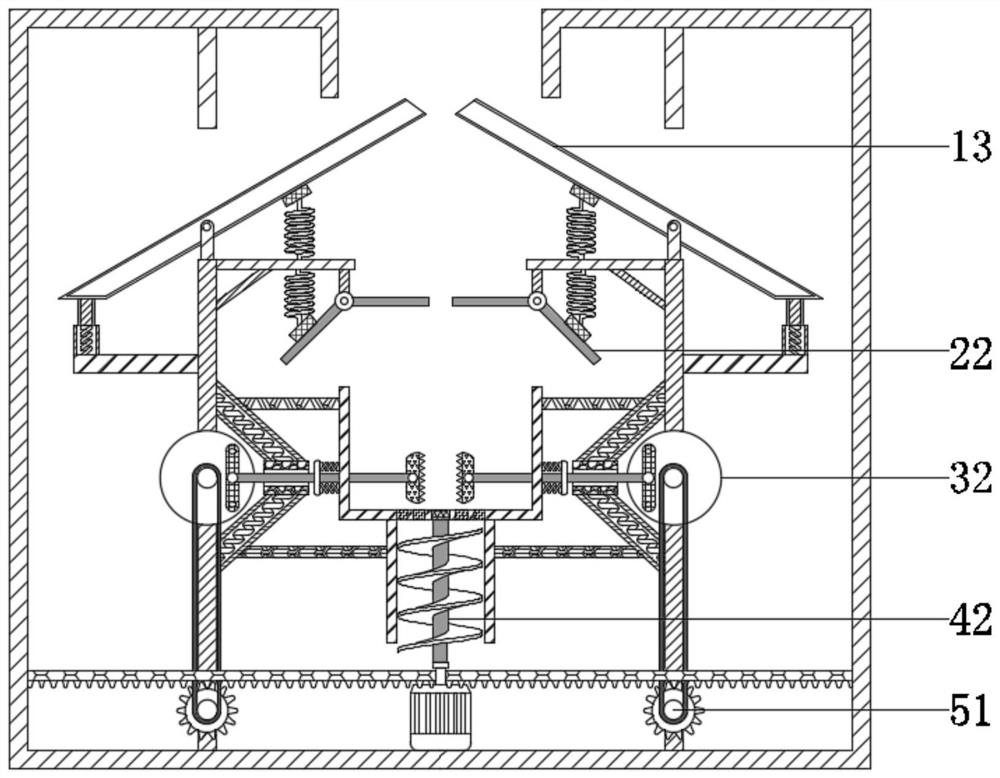

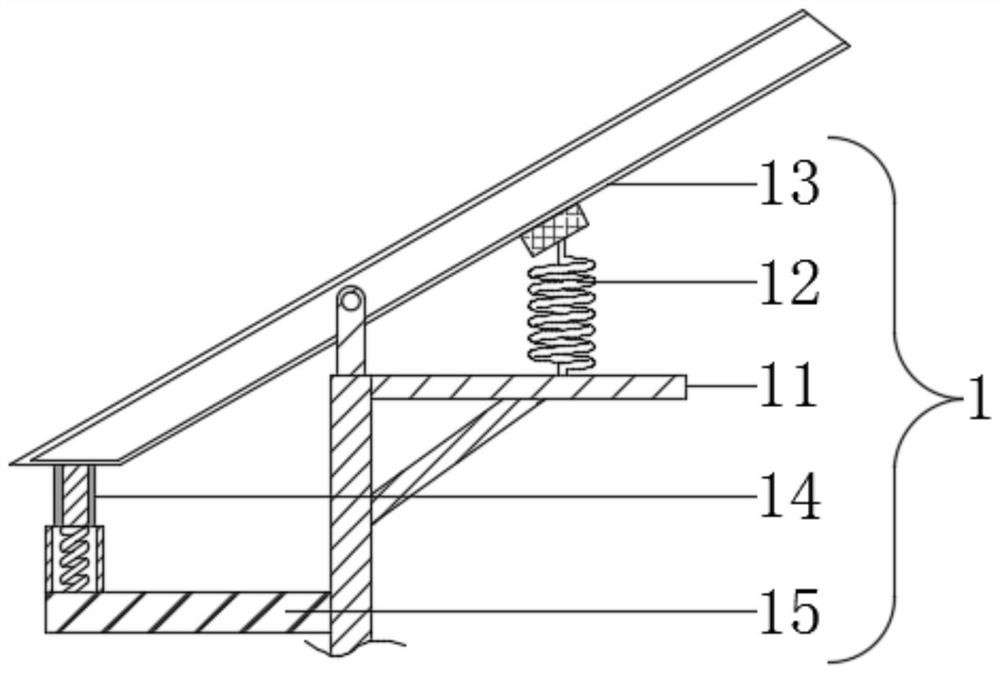

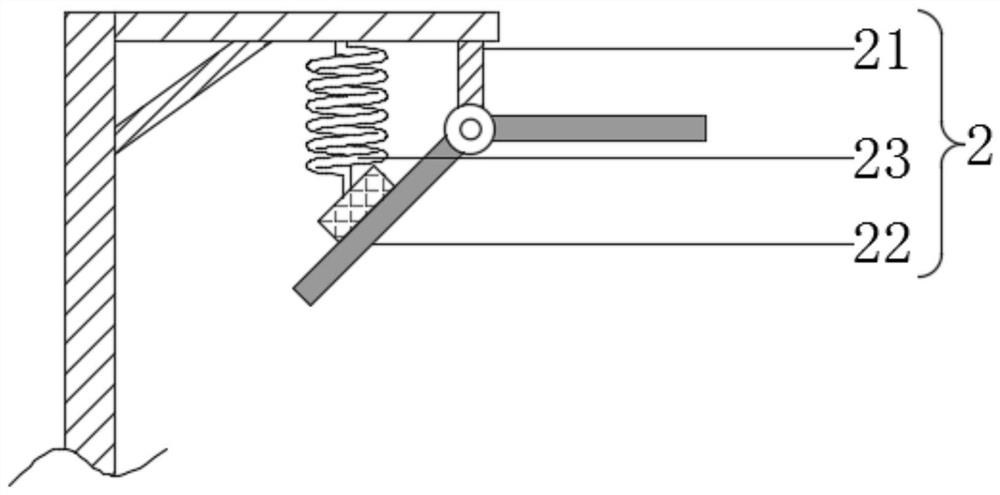

[0025] see Figure 1-4 , a device for automatically recovering and reusing construction waste slag blocks after crushing, including a crushing mechanism 3 and a transmission mechanism 5. The crushing mechanism 3 includes a fixed frame 31, and the middle part of the fixed frame 31 is rotatably connected to a runner 32. The front of the runner 32 A slide plate 33 is fixedly connected to the position deviated from the center of the circle, and the center of the slide plate 33 is connected with a push rod 34 for rotation. The inside of 39 is fixedly connected to the limiting groove 35, the top of the base 39 is fixedly connected to the crushing frame 37, and the bottom of the crushing frame 37 is provided with a hole 38, and the crushing mechanism 3 is arranged symmetrically on the left and right, wherein the push rod 34 is slidably connected to the inside of the limiting groove 35 , the push rod 34 is socketed in the lower half of the crushing frame 37.

[0026] Further, it also...

Embodiment 2

[0029] see Figure 5-6 , a device for automatic recovery and reuse of construction waste slag blocks after crushing, including a crushing mechanism 3 and a transmission mechanism 5, the transmission mechanism 5 includes a gear 51, the central transmission of the gear 51 is connected to a conveyor belt 52, and the outer side of the gear 51 is meshed with a rack The plate 53, the conveyor belt 52 is connected to the center of the runner 32, the center of the rack plate 53 is clamped with a motor 41, and also includes a belt mechanism 4, which includes a motor 41, and the top of the motor 41 is connected to a rotating plate 42 , the outer side of the rotating plate 42 is fixedly connected with a spiral plate 43 .

[0030] After the slag block is broken into small pieces, it falls downward from the hole groove 38. At this time, the motor 41 is energized to rotate, which drives the rotating plate 42 to rotate, and drives the spiral plate 43 to rotate, and the small slag block falls...

Embodiment 3

[0032] see Figure 1-6 , a device for automatically recovering and reusing construction waste slag blocks after crushing, including a crushing mechanism 3 and a transmission mechanism 5, the crushing mechanism 3 includes a fixed frame 31, the middle part of the fixed frame 31 is rotatably connected to a runner 32, and the front of the runner 32 The position deviated from the center of the circle is fixedly connected with a slide plate 33, and the center of the slide plate 33 is connected with a push rod 34, and the end of the push rod 34 away from the slide plate 33 is connected with a toothed push head 36, and the middle part of the fixed frame 31 is fixedly connected with a base 39. The inside of 39 is fixedly connected to the limiting groove 35, the top of the base 39 is fixedly connected to the crushing frame 37, the bottom of the crushing frame 37 is provided with a hole groove 38, and the crushing mechanism 3 is arranged symmetrically on the left and right, wherein the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com