Multi-stage seed cleaner

A technology for cleaning machines and seeds, applied in the field of cleaning machines, can solve the problems of resource waste, impurities and small particle seed recovery, and achieve the effect of improving work efficiency and good recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

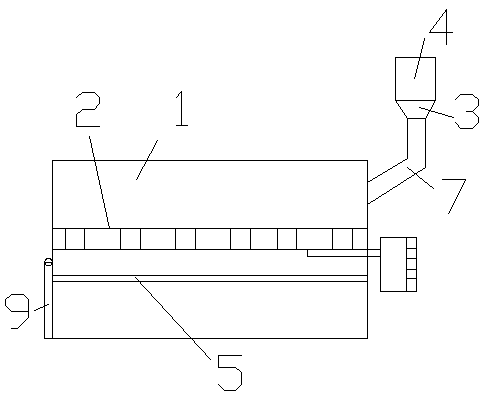

[0014] A multi-stage seed cleaning machine is provided with a cabinet 1 and a cleaning device 2, and is characterized in that: a cleaning device 2 is arranged in the cabinet 1, and the cleaning device 2 is a vibrating screen. The top of the cabinet 1 is provided with a feed port 3, the feed port 3 is provided with a butt joint 4, the inner side of the butt joint 4 is provided with a connecting thread, and the lower side of the vibrating screen is provided with a distribution plate 5, the said distribution plate 5 is inserted into the chassis.

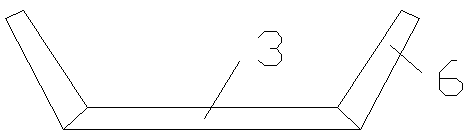

[0015] The material distribution plate 5 is a stainless steel plate, and side plates 6 are arranged on both sides of the material distribution plate 5 .

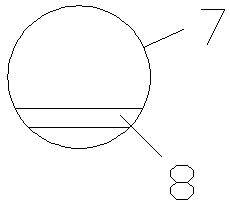

[0016] The side plate 6 and the stainless steel plate are welded and fixed to each other, and a conveying pipe 7 is arranged on the lower side of the feed inlet 3 .

[0017] The delivery pipe 7 is a rubber pipe, and a sliding plate 8 is arranged inside the rubber pipe.

Embodiment 2

[0019] A multi-stage seed cleaning machine is provided with a cabinet 1 and a cleaning device 2, and is characterized in that: a cleaning device 2 is arranged in the cabinet 1, and the cleaning device 2 is a vibrating screen. The top of the cabinet 1 is provided with a feed port 3, the feed port 3 is provided with a butt joint 4, the inner side of the butt joint 4 is provided with a connecting thread, and the lower side of the vibrating screen is provided with a distribution plate 5, the said distribution plate 5 is inserted into the chassis.

[0020] The material distribution plate 5 is a stainless steel plate, and side plates 6 are arranged on both sides of the material distribution plate 5 .

[0021] The side plate 6 and the stainless steel plate are welded and fixed to each other, and a conveying pipe 7 is arranged on the lower side of the feed inlet 3 .

[0022] The delivery pipe 7 is a rubber pipe, and a sliding plate 8 is arranged inside the rubber pipe.

[0023] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com