Preparation method and application of cuprous-oxide-loaded-on-foam-nickel composite graphene oxide photocatalyst

A cuprous oxide, composite oxidation technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve secondary pollution, long reaction time, preparation procedures Complicated and other problems, to achieve the effect of good recycling and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of the present invention comprises the following steps:

[0028] 1) Graphene oxide was prepared by the Hummer method, and a graphene oxide dispersion system of 2 mg / mL-4 mg / mL was obtained by ultrasonication;

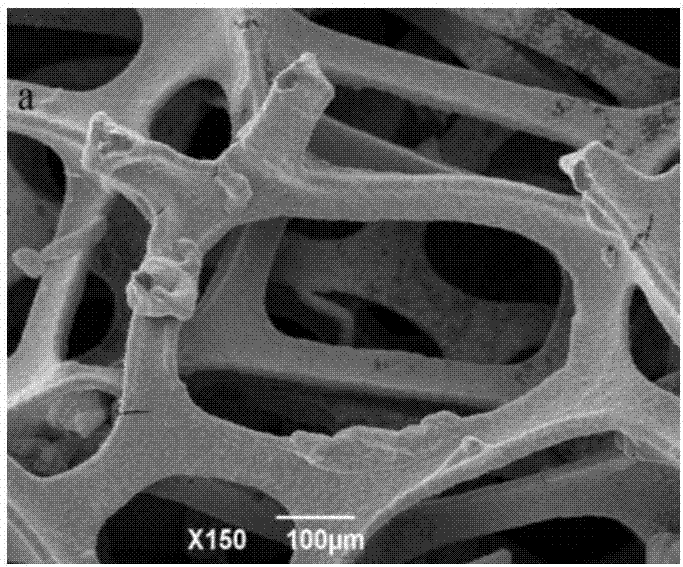

[0029] 2) Soak the three-dimensional nickel foam (NF) in acetone for 1 hour, then treat it with 1mol / L hydrochloric acid for 10 minutes, and then wash it with ultrasonic water. After 5 min in the ene dispersion system, take it out and dry it in the air to get the GO@NF composite material;

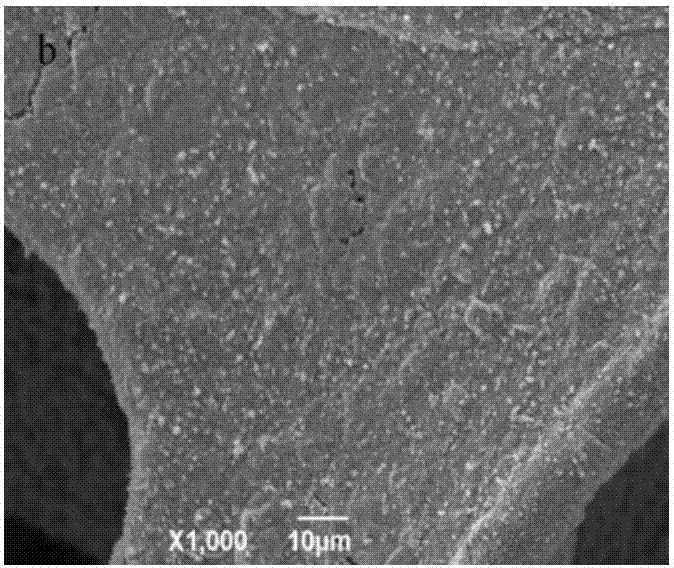

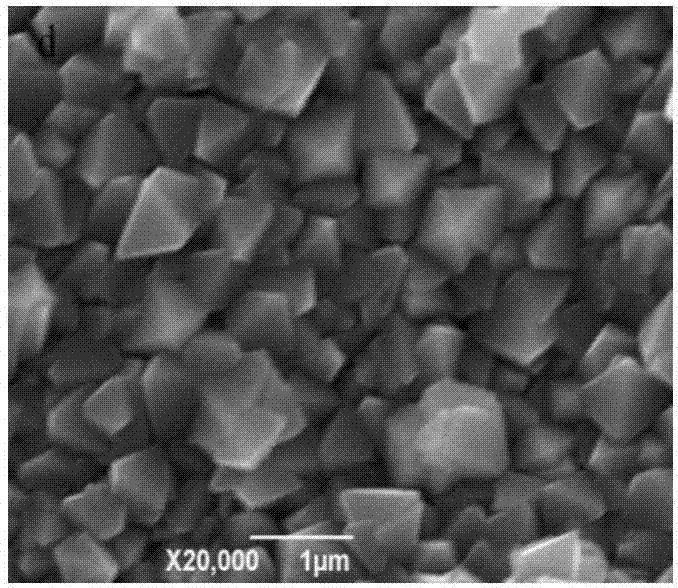

[0030]3) With graphene oxide@foam nickel (GO@NF) as working electrode, platinum electrode as auxiliary electrode, calomel electrode as reference electrode, 0.1M CH 3 COONa and 0.02M CuSO 4 The mixed solution is the supporting electrolyte, and its pH is 6.0-7.0. After 1h-2h of constant potential deposition, a three-dimensional NF-loaded Cu 2 O / GO composite photocatalyst, wherein the constant potential voltage is -0.2V~-0.3V.

[0031] A preparation met...

Embodiment 1

[0033] (1) Graphene oxide was prepared by the Hummer method, and a graphene oxide dispersion system of 4 mg / mL was obtained by ultrasonication.

[0034] (2) Soak the nickel foam in acetone for 1 hour, then treat it with 1mol / L hydrochloric acid for 10 minutes, and then wash it with ultrasonic water. After immersing the pretreated NF size (1 × 5 cm) in 4 mg / mL graphene oxide dispersion system for 5 min, it was taken out and air-dried to obtain GO@NF composites.

[0035] (3) With GO@NF as working electrode, platinum electrode as auxiliary electrode, and calomel electrode as reference electrode, 0.1MCH 3 COONa and 0.02M CuSO 4 The mixed solution is the supporting electrolyte, pH = 6.0, and three-dimensional NF-loaded Cu is obtained after potentiostatic deposition at -0.2V for 1 h 2 O / GO composite photocatalyst.

[0036] The prepared Cu 2 O / GO@NF composite size (1×5cm), placed in oilfield wastewater containing 92mg / L HPAM, added 20mmol / L H 2 o 2 , magnetic sub-stirring, afte...

Embodiment 2

[0038] (1) Graphene oxide was prepared by the Hummer method, and a 2 mg / mL graphene oxide dispersion was obtained by ultrasonication.

[0039] (2) Soak the nickel foam in acetone for 1 hour, then treat it with 1mol / L hydrochloric acid for 10 minutes, and then wash it with ultrasonic water. After soaking the pretreated NF (1 × 5 cm) in 2 mg / mL graphene oxide dispersion system for 5 min, it was taken out and air-dried to obtain GO@NF composites.

[0040] (3) With GO@NF as working electrode, platinum electrode as auxiliary electrode, and calomel electrode as reference electrode, 0.1MCH 3 COONa and 0.02M CuSO 4 The mixed solution is the supporting electrolyte, pH = 6.5, and three-dimensional NF-loaded Cu is obtained after potentiostatic deposition at -0.25V for 2 hours 2 O / GO composite photocatalyst.

[0041] (4) the prepared Cu 2 O / GO@NF composite material size (1×5cm), placed in oilfield wastewater containing 94mg / L HPAM, added 15mmol / L H 2 o 2 , magnetic sub-stirring, aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com