Construction waste soil material recycling device

A technology of recycling device and construction waste, applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of low economic benefit and pollute the environment, and achieve the effect of improving economic benefit and convenient recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

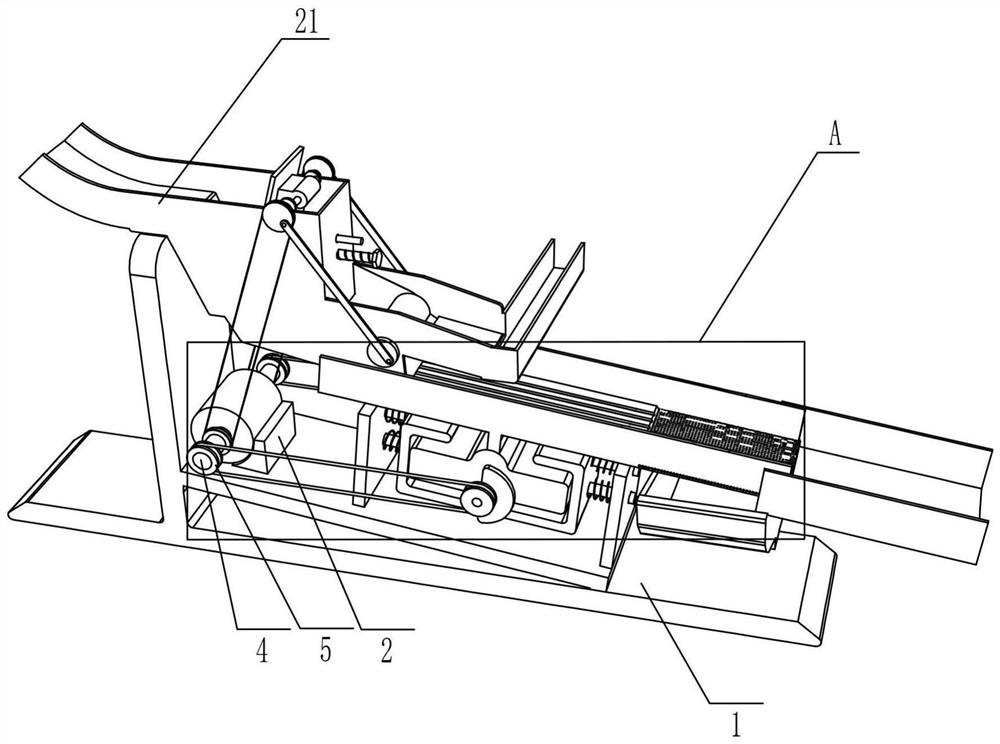

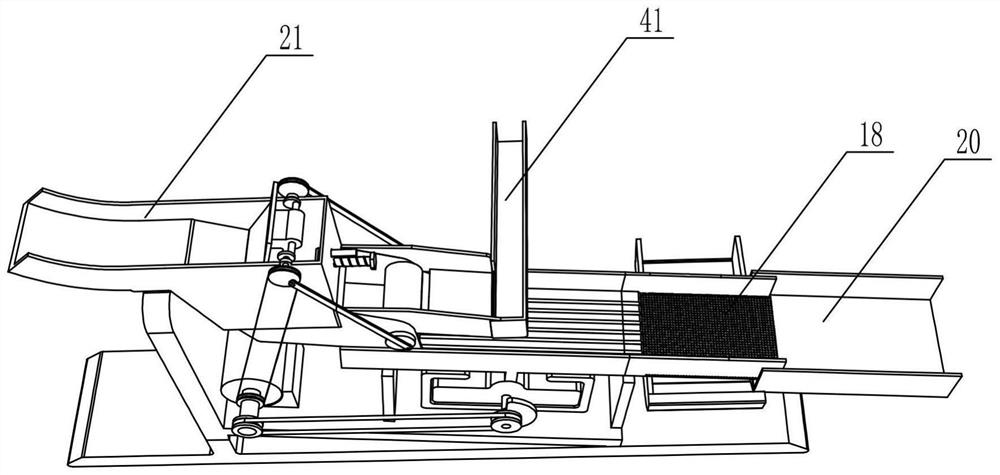

[0025] Such as Figure 1-Figure 8 As shown, a construction waste earth material recovery device includes a base 1, a clamp block 2, a biaxial motor 3, a rotating shaft 4, a pulley 5, a vibration mechanism, a conveying frame 17, a screen 18, and a feeding frame 19 And the material receiving frame 20, the clamp block 2 that plays a supporting role is fixedly installed on the base 1, and the biaxial motor 3 that plays a driving role is fixedly installed on the clamp block 2 and is close to the base 1. The rotating shaft-4 of the transmission effect is respectively fixedly installed on the two output ends of the biaxial motor 3 and arranged symmetrically. The vibrating mechanism is installed on the base 1, the conveying frame 17 that plays a role in transmission is fixedly installed on the vibrating mechanism, and the screening net 18 that can screen out fine soil materials is fixedly installed on the right end of the conveying frame 17, and the described screen used for receiving...

Embodiment 2

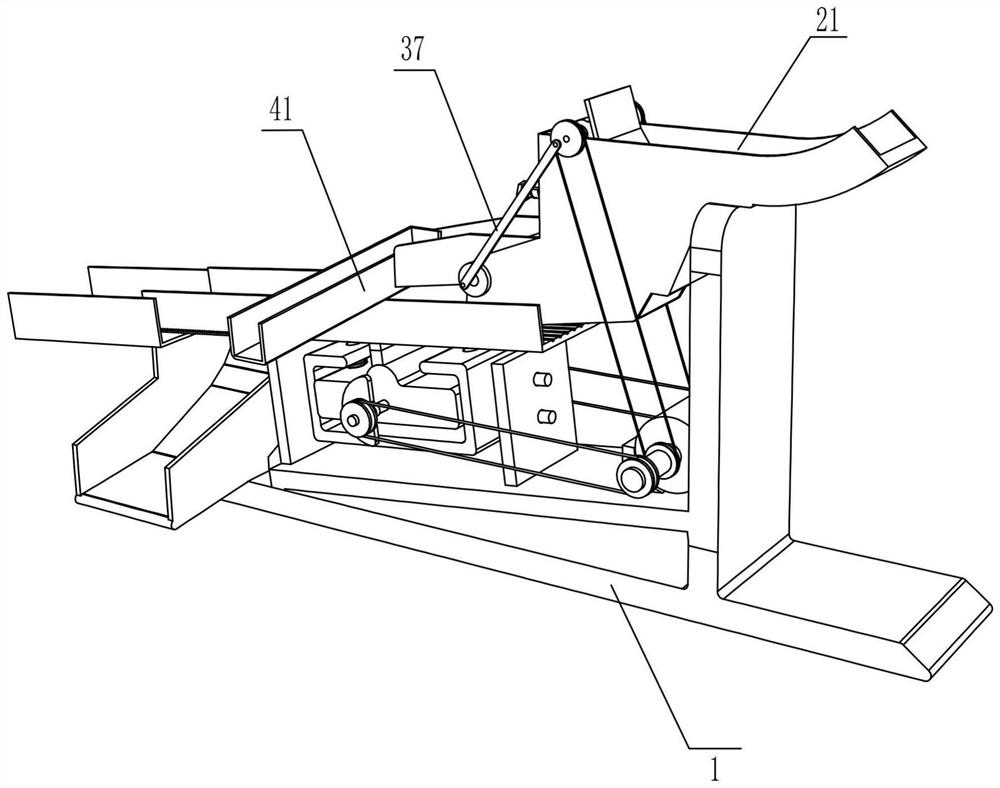

[0031] On the basis of Example 1, such as Figure 1-Figure 8 As shown, it also includes a screening mechanism that can screen out metal waste. The screening mechanism includes a rotating disk 2 36, a connecting rod 37, a magnet ring 38, a fixed plate 39, a scraper 40 and a material protection frame 41, and the two rotating disk 2 36 are respectively fixedly installed on the front and rear ends of the rotating shaft 4 35 and are close to the guardrail frame 34. The lower ends of the two connecting rods 37 that play a transmission role are respectively connected in a rotational manner with the two rotating discs 2 36 through the tip rods, and the upper ends are connected through the tip rods. It is connected with pulley three 23 side rotation, and the magnetic magnet ring 38 is fixedly installed on the rotating shaft four 35 and between the two guardrail frames 34, and the fixed plate 39 that plays a fixed role is fixedly installed on the On the two guardrail frames 34 and close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com