A qualified inspection device for the production of led fluorescent lamps

A technology of LED fluorescent lamp and detection device, applied in sorting and other directions, can solve the problems of low detection rate, high labor cost, etc., and achieve the effect of preventing fragmentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

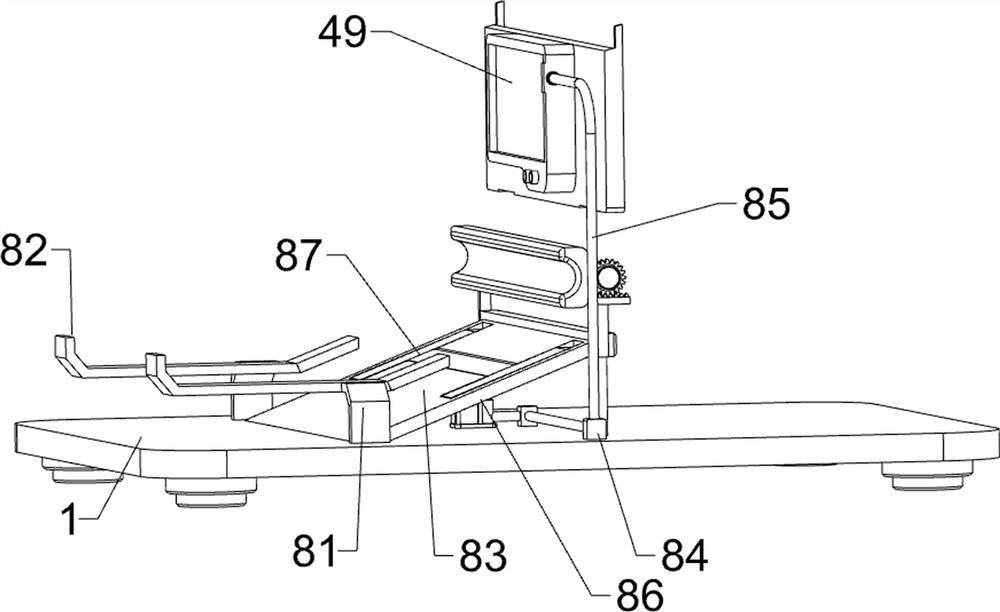

[0080] A qualified detection device for the production of LED fluorescent lamps, such as figure 1 As shown, it includes a base plate 1, a rotating shaft motor 2, a first support column 3, a detection mechanism 4, and a feeding mechanism 5. The rotating shaft motor 2 is connected to the upper right side of the base plate 1, and the first support is connected to the front and rear sides of the upper portion of the base plate 1. The column 3 is connected with a detection mechanism 4 on the upper side of the bottom plate 1 , the detection mechanism 4 is connected with the rotating shaft motor 2 , and the upper side of the bottom plate 1 is connected with a feeding mechanism 5 .

[0081] When the device needs to be used, the user can place the LED light tube in the detection mechanism 4, and then start the rotating shaft motor 2, and the rotating shaft motor 2 reverses to drive the detection mechanism 4 to move to the left, and then drives the detection mechanism 4 to move inward, a...

Embodiment 2

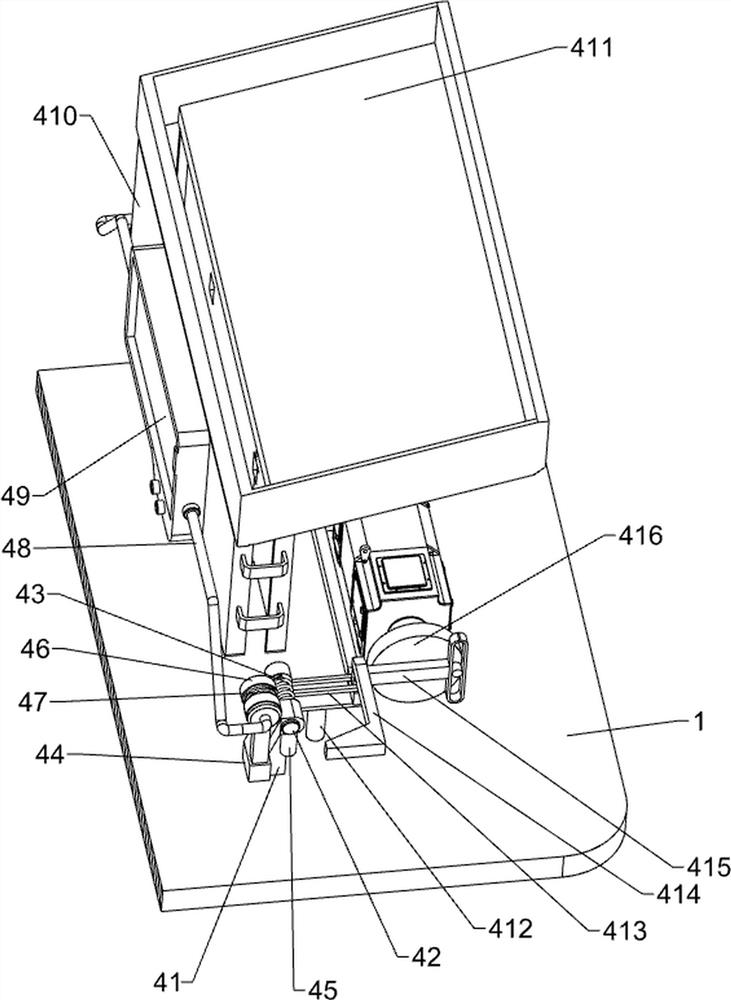

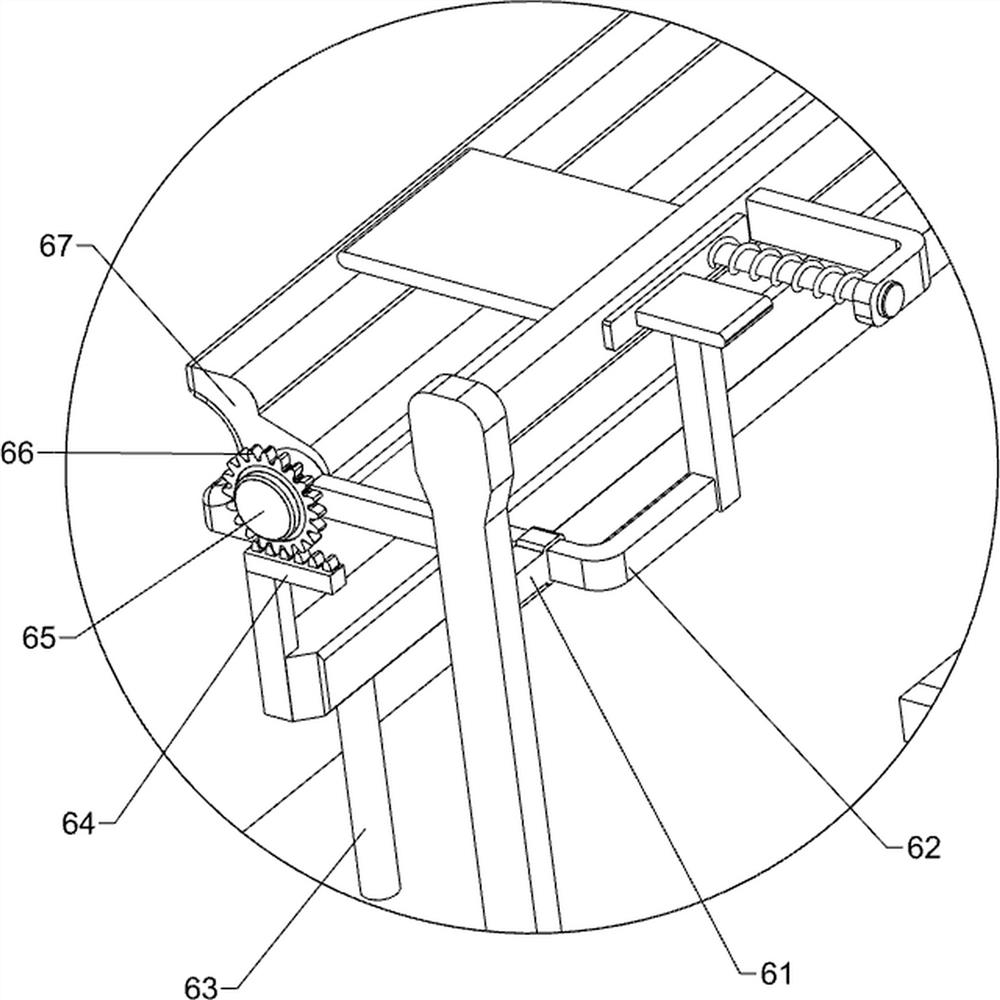

[0083] On the basis of Example 1, such as figure 2 As shown, the detection mechanism 4 includes a second support column 41, a first slide bar 42, a first spring 43, a connecting rod 44, a first push rod 45, a contact block 46, a second spring 47, a first electric wire 48, a display 49. Guide plate 410, blanking basket 411, third support column 412, slide rail 413, second ejector rod 414, second slide bar 415 and turntable 416, the upper and lower sides of bottom plate 1 are connected with second support column 41 , the first sliding rod 42 is slidably connected to the second support column 41, the connecting rod 44 is connected to the first sliding rod 42, the first spring 43 is wound on the first sliding rod 42, and the first spring 43 is located at The inner side of the connecting rod 44 and the lower side of the connecting rod 44 are connected with the first push rod 45, and the connecting rod 44 is connected with the contact block 46 in a sliding manner, and the contact b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com