Pressurizing common-rail oil injection system

A technology of fuel injection system and common rail, which is applied in the direction of charging system, fuel injection device, engine components, etc., can solve the problems of difficult control of fuel injection rate, low injection pressure, etc., so as to facilitate the design and layout, reduce emissions and energy Loss, effect of compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

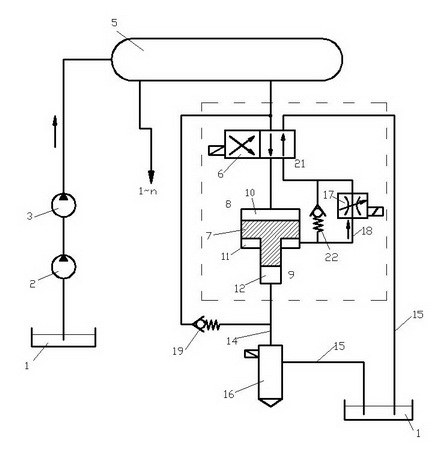

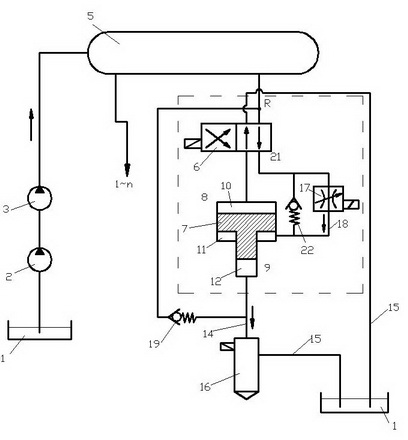

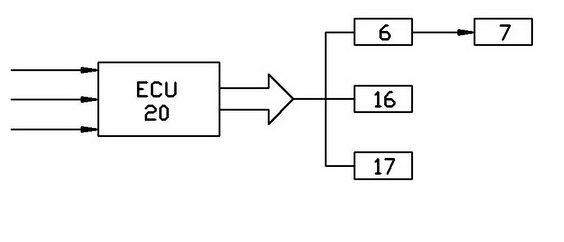

[0025] The present invention includes a high-pressure oil supply pump 3, a common rail pipe 5, a high-pressure oil pipe 14, and an oil return pipe 15, and is characterized in that it also includes a control valve 6, a booster valve 7, an electric control unit 20 and a plurality of electronically controlled fuel injectors 16, The booster valve 7 is installed behind the common rail pipe 5 and each control valve 6, and is connected to each other with a high-pressure oil pipe 14,

[0026] a. The control valve 6 is a two-position four-way high-speed electromagnetic reversing valve, which is supplied with fuel at the common rail pressure Pc by the common rail pipe 5, and can quickly supply fuel from the upper chamber 10 of the booster valve 7 Switch to supply oil to the lower chamber 11 of the booster valve 7, and the reversing action and reversing time of the control valve 6 are controlled by the above-mentioned electronic control unit 20;

[0027] b. The above-mentioned supercharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com