Loading and unloading transmission device for machine tool

A material feeding and machine tool technology, which is applied in the field of machine tool loading and unloading and feeding devices, can solve the problems of not being able to grab workpieces, instability, shaking, etc., and achieve the effects of reducing labor intensity, convenient production, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

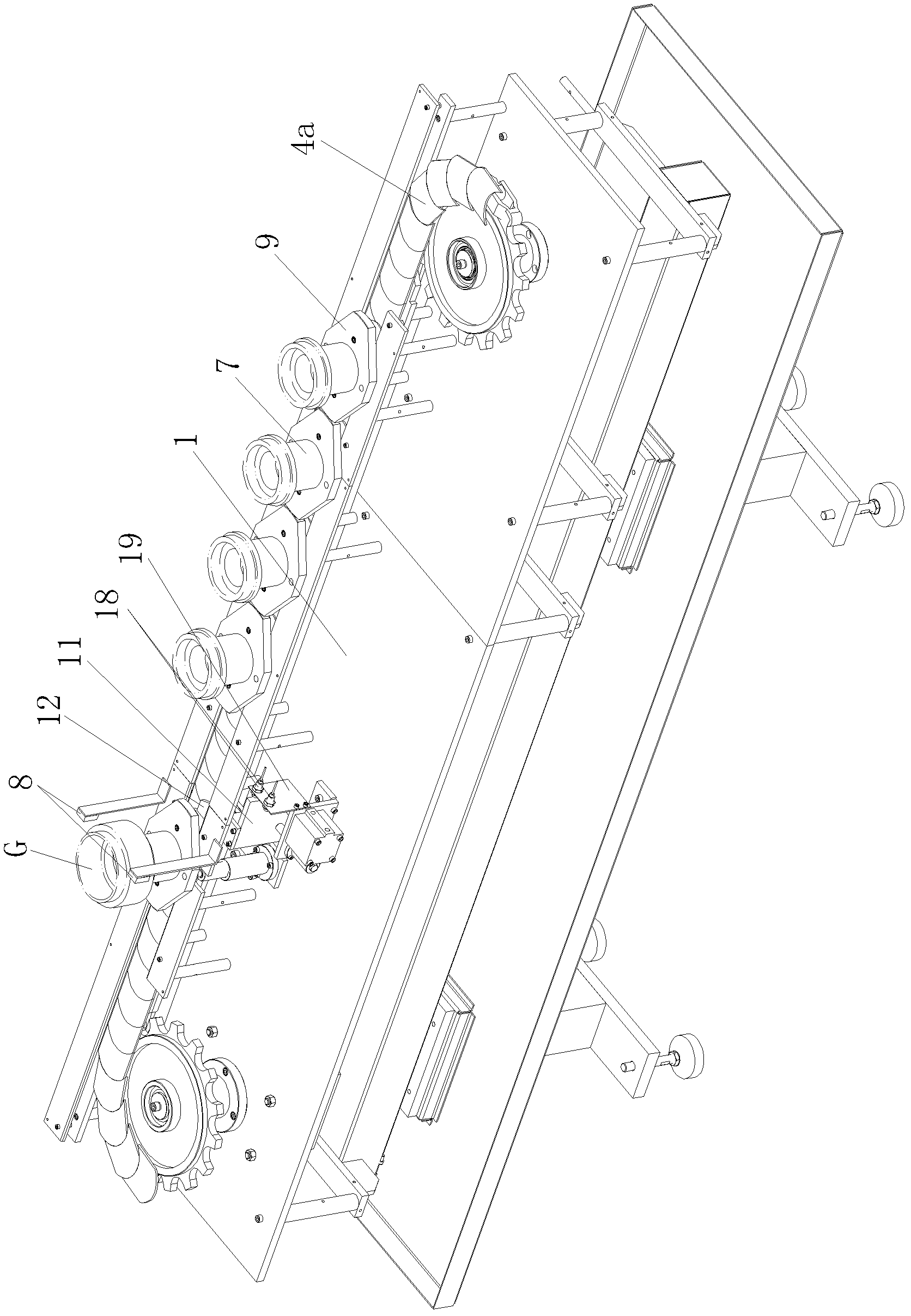

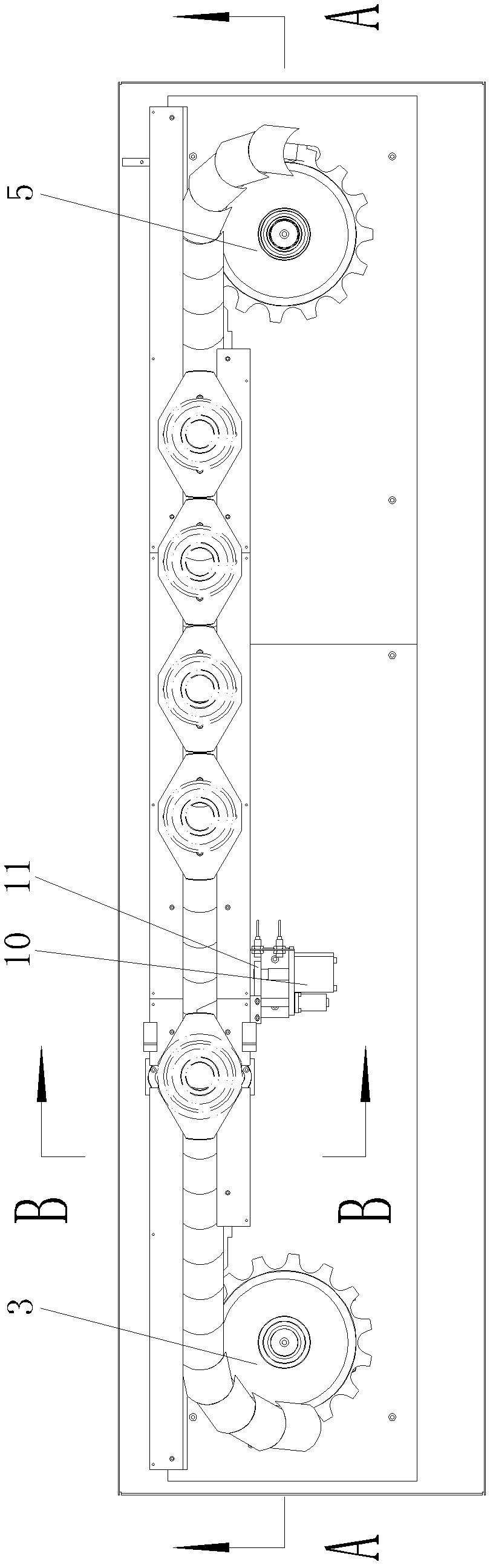

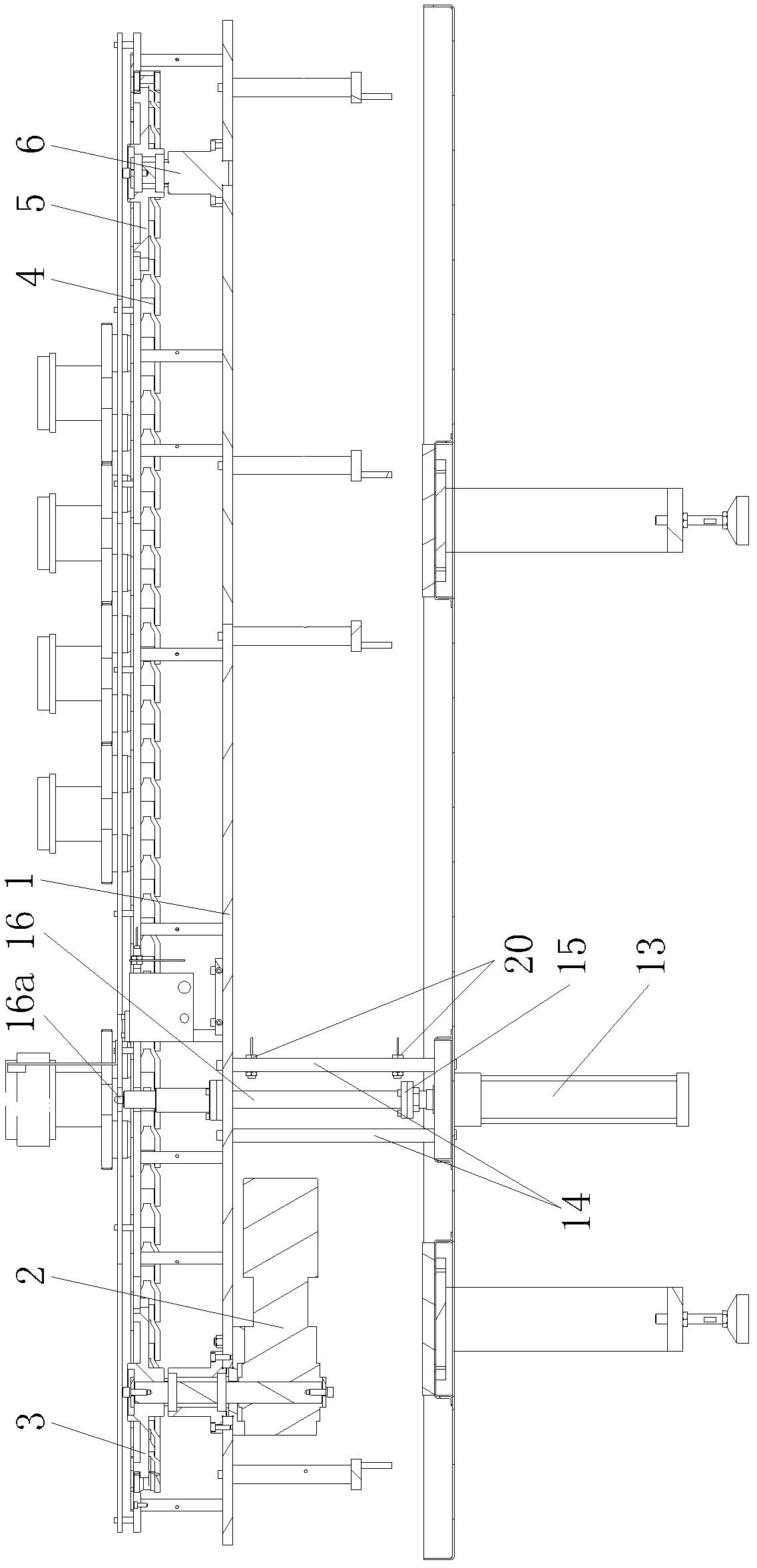

[0020] Such as Figure 1-5 As shown, the present invention mainly consists of an intermediate plate 1, a reducer 2, a driving sprocket 3, a warp chain 4, a driven sprocket 5, a vertical support shaft 6, a workpiece bracket 7, a shooting switch 8, a pallet 9, and a cylinder 10. Vertical plate 11, horizontal baffle plate 12, oil cylinder 13, side plate 14, horizontal plate 15, push rod 16, small cylinder 17, first proximity switch 18, vertical mounting plate 19, second proximity switch 20 and The cylinder mounting plate 21 is formed, wherein the reducer 2 is hoisted on the left part of the middle plate 1, the reducer 2 is the power source of the bin device, and the upper end of the output shaft of the reducer 2 is coaxially fitted with the active chain Wheel 3, the driving sprocket 3 is connected with the driven sprocket 5 through the chain 4. The above-menti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com