Trolley-type chain mud scraper

A mud scraper and trolley-type technology, which is applied in the field of sewage treatment equipment, can solve problems such as the difficulty of sludge treatment, and achieve the effect of remarkable mud-water separation effect, stable operation and strong anti-corrosion ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

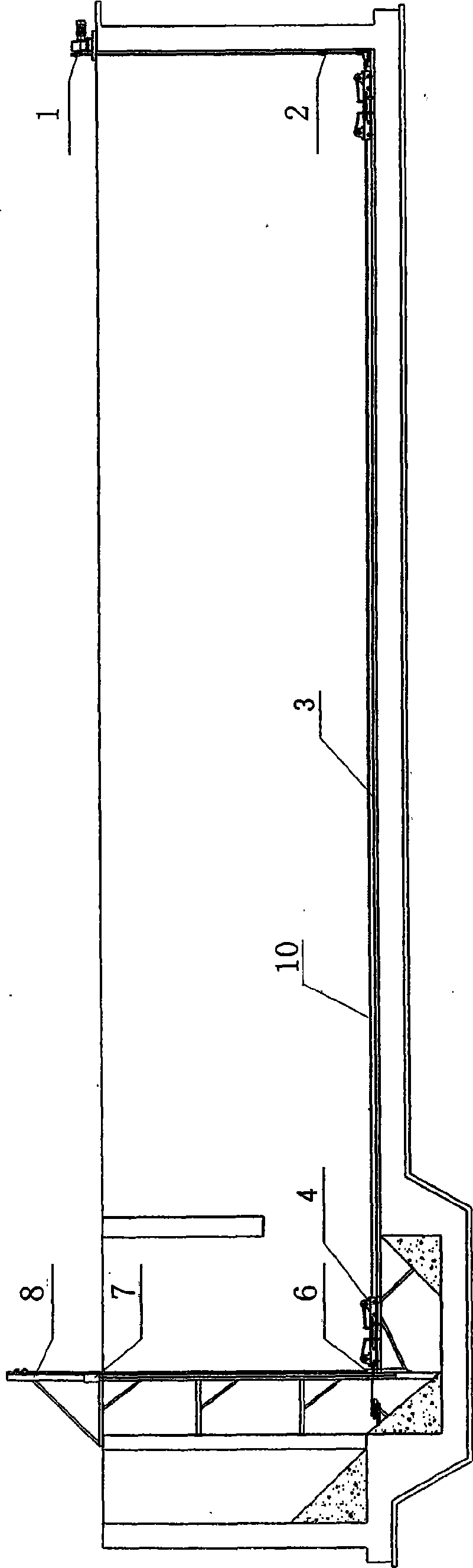

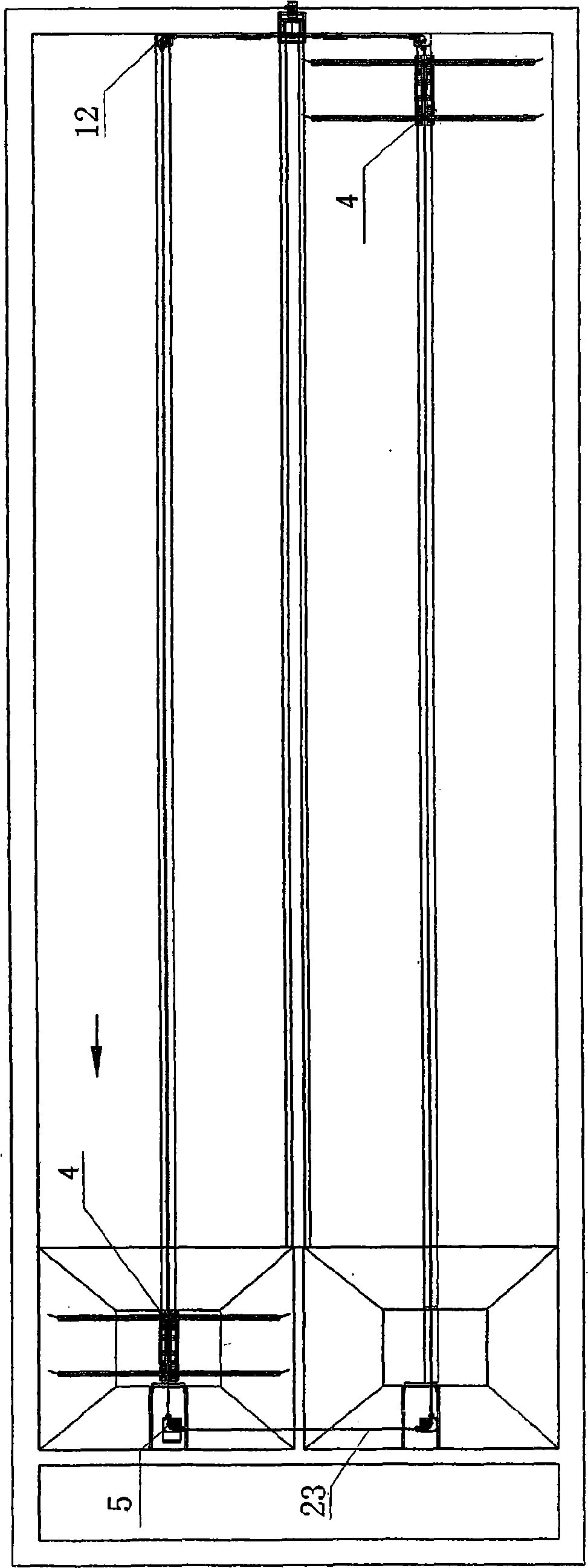

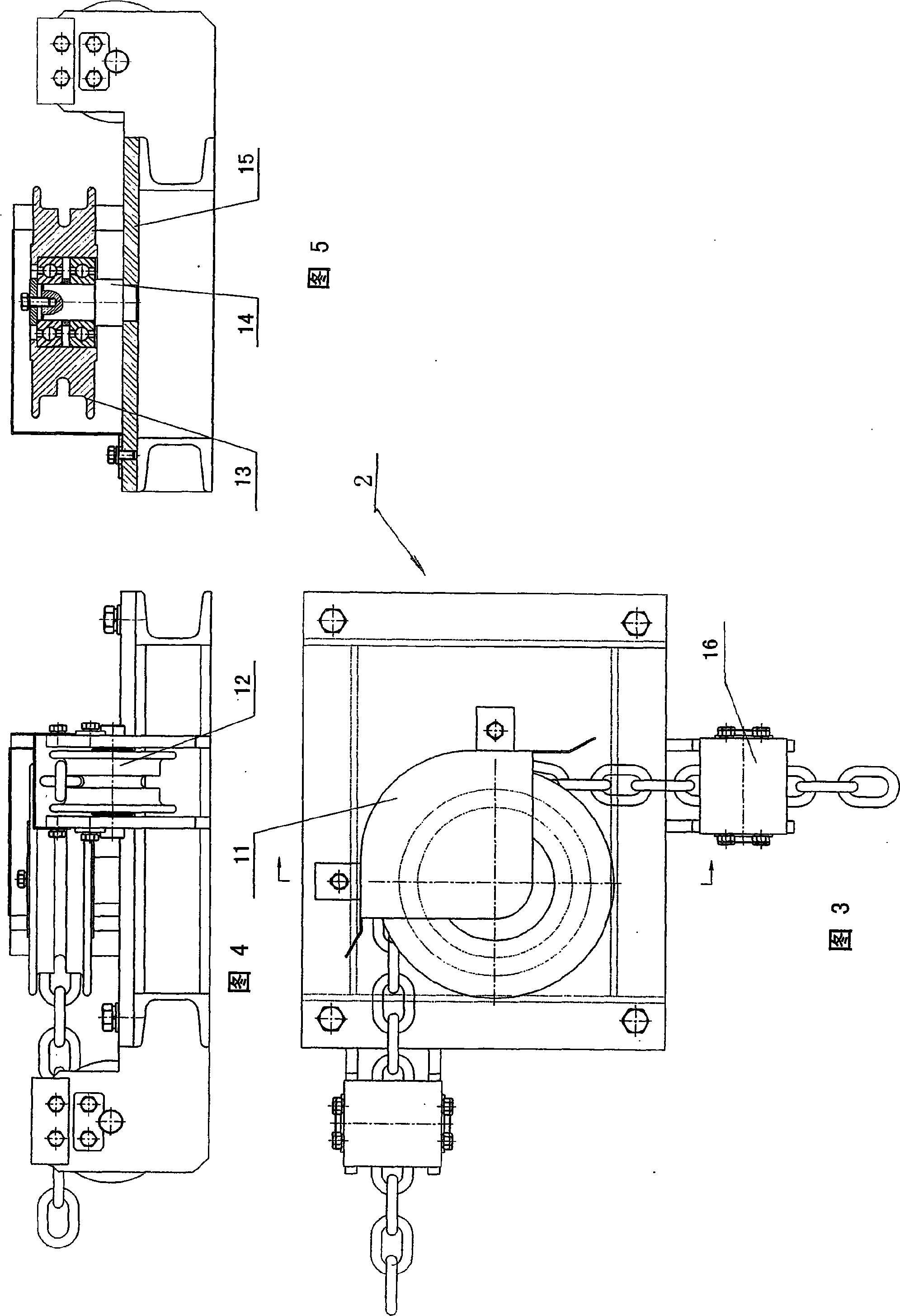

[0058] For the mud scraper shown in the figure, two mud scraper trolleys 4 are set on the track 3 at the bottom of the pool, one is at the end of the mud scraping stroke, and the other is at the starting point of the mud scraping stroke, each mud scraper The front end of the trolley is connected to the traction mechanism by the wire rope 23 of the wire rope guide wheel 84, and the rear parts of the two mud scraping machine trolleys are connected to the traction sprocket to form a closed running chain, which scrapes mud back and forth in one direction. In the traction device 1, the output shaft end of the reducer is equipped with a traction sprocket, which is connected to the two mud scraping trolleys 4 through the traction chain. Under the traction of the traction sprocket, the two mud scraping trolleys are driven by the forward and reverse rotation of the motor Back and forth staggered operation, the speed is the same but the direction is opposite, and there is a mud pit at on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com