Composite sandstone powder concentrator

A powder classifier and compound technology, applied in the direction of solid separation, separating solids from solids with air flow, grain processing, etc., can solve the problem of uneven feeding, short time, and reduced separation efficiency of sand and gravel separation systems and effects, etc., to achieve the effect of increasing the processing capacity, improving the efficiency and effect of sorting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

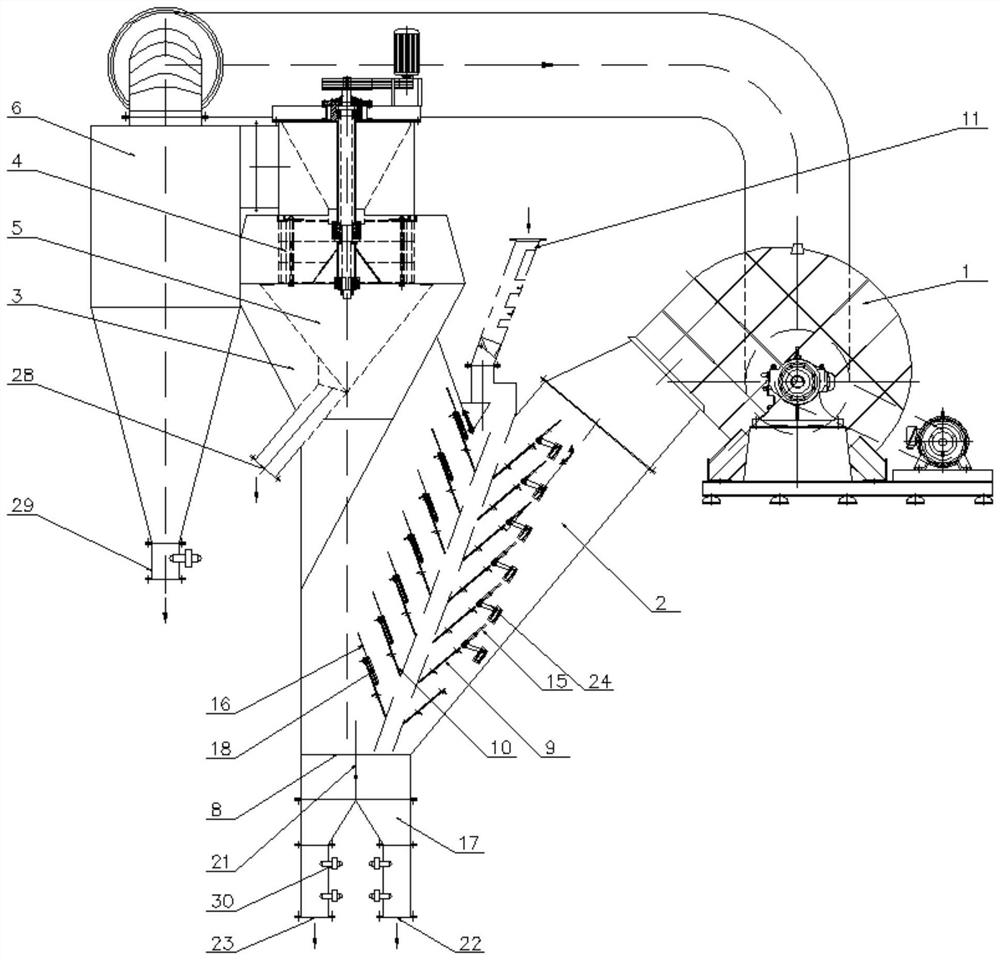

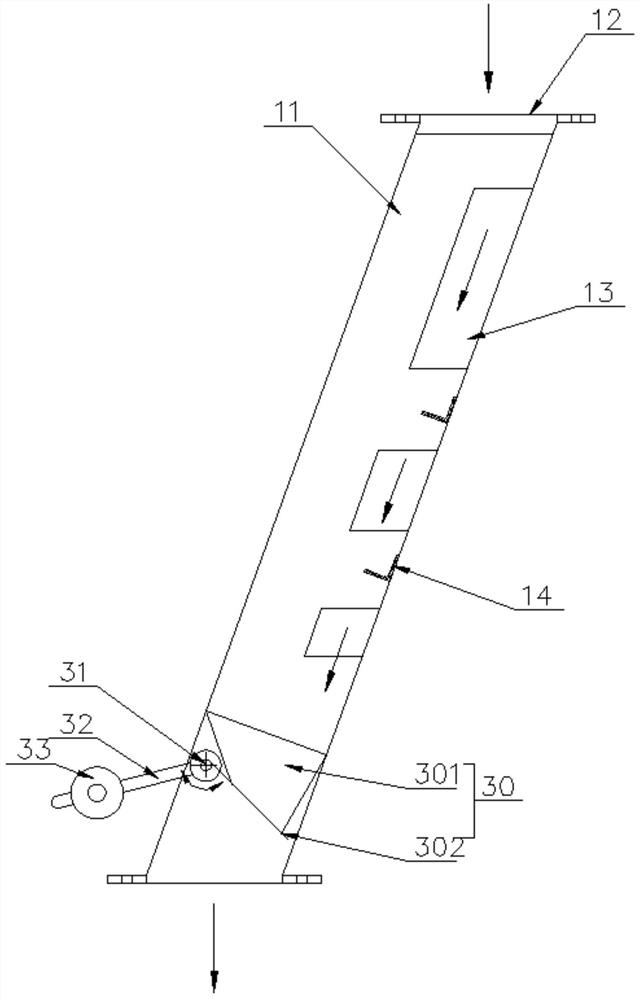

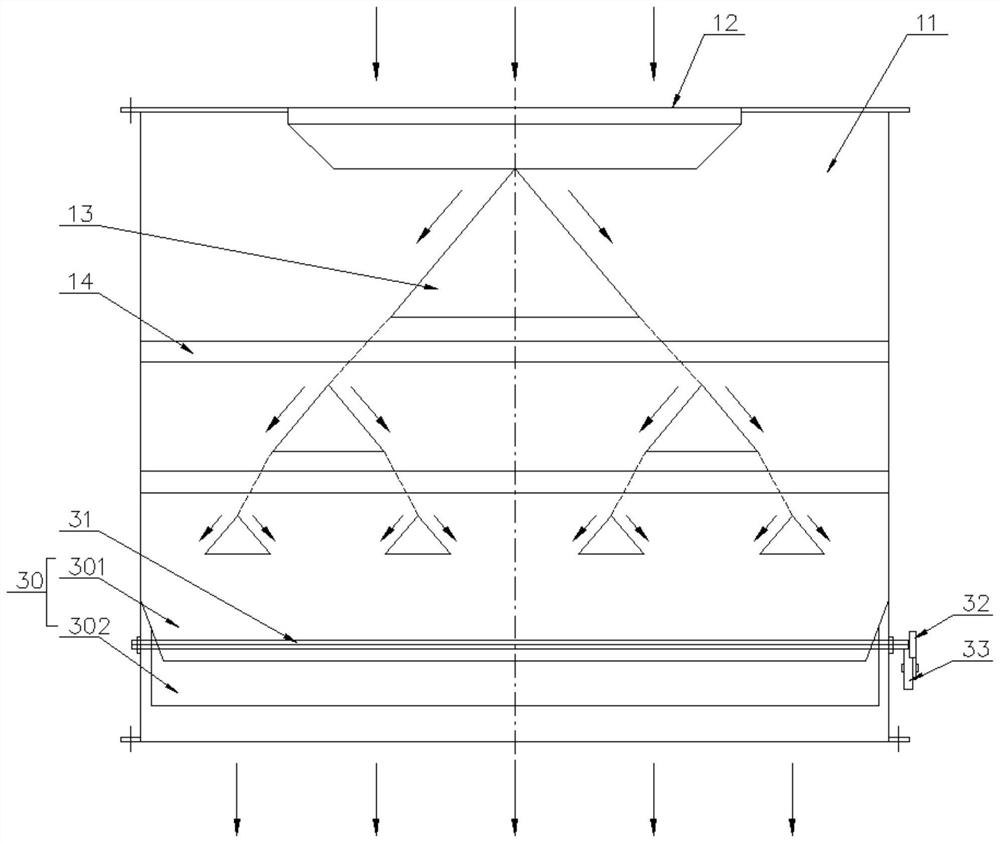

[0030] A composite sand and gravel powder separator, comprising a fan 1, a V-selecting device 2 connected to the air outlet of the fan 1, a middle-sand cone bucket 3 connected to the air outlet of the V-separation device 2, and a center-sand cone bucket 3 rotating inside The cage rotor 4 and the fine sand cone bucket 5 at the bottom of the cage rotor 4, and at least one cyclone separator 6 connected to the air outlet of the cage rotor 4, the top and bottom of the V selection device 2 are respectively provided with a feed inlet 7 And the discharge port 8, the V selection device 2 is provided with two groups of oppositely inclined and vertical V selection device 2 side walls between the feed port 7 and the discharge port 8. The first fixed dispersing blade 9 and the second Two fixed and scattered blades 10, the air outlet of the cyclone separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com