Carboxylic acids graft copolymer concrete strengthening agent

A graft copolymer and concrete technology, applied in the field of carboxylic acid graft copolymer, can solve the problems of unfavorable sustainable development, heavy environmental pollution and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

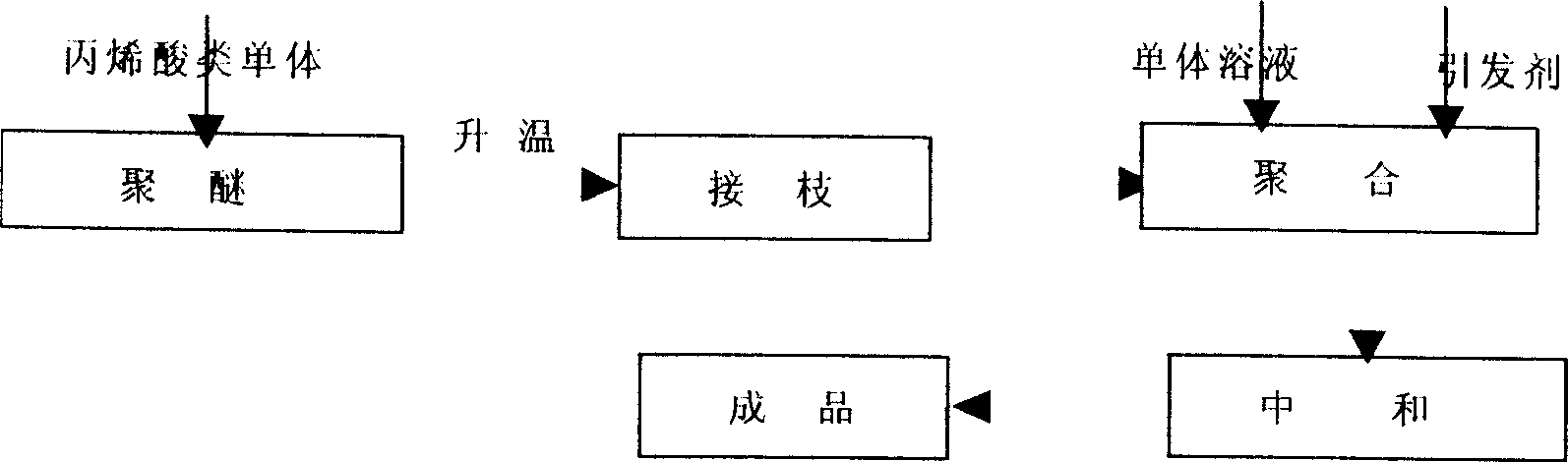

Method used

Image

Examples

Embodiment 1

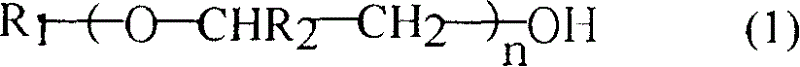

[0069] a) Grafting reaction

[0070] 240g (0.2mol) polyethylene glycol-propylene glycol random copolymer (EO / PO=60:40, M w 1200), stirring and heating up to 60°C, adding 98g (1.0mol) of maleic anhydride, and adding 12g of p-toluenesulfonic acid, while stirring to form a uniform solution, then raising the temperature to 145°C for grafting reaction, and maintaining the reaction for 3 hours to obtain Sheath red transparent liquid.

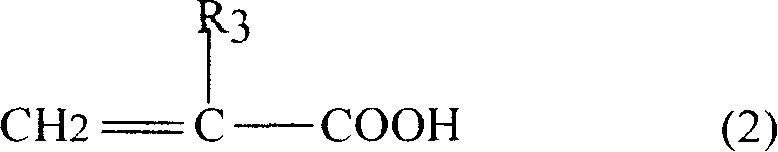

[0071] b) Free radical polymerization

[0072] Then add a certain amount of distilled water and a little catalyst to the highly viscous reaction mixture, lower the temperature to 80-95°C, and simultaneously titrate the monomer solution (containing 30.5g acrylamide) and the composite initiator solution (K 2 S 2 o 8 +30%H 2 o 2 ), 90min dripping, and heat preservation reaction 3h, naturally cooled to below 40 ℃ and added alkali to obtain bright brown red transparent solution, its pH value is 7.8 (solid content 38.5%), weight average molecular weig...

Embodiment 2

[0074] a) Grafting reaction

[0075] According to the procedure described in production example 1, drop into 200g (0.2mol) polypropylene glycol (average molecular weight is 1000), 37.5g (0.05mol) polyethylene glycol monomethyl ether (average molecular weight is 750) stir and heat up to 60 ℃, add 65g (0.5mol) of itaconic acid, and 11g of p-toluenesulfonic acid was added to heat up, while stirring to form a uniform solution, then the temperature was raised to 145°C for grafting reaction, and the reaction was kept for 5 hours to obtain a red transparent liquid.

[0076] b) Free radical polymerization

[0077] Then add a certain amount of distilled water and a little catalyst to the highly viscous reaction mixture, lower the temperature to 80-95°C, and simultaneously titrate the monomer solution (containing 19.2g acrylic acid) and the composite initiator solution (K 2 S 2 o 8 +30%H 2 o 2 ), 120min dripping, and insulation reaction 3h, natural cooling to below 40 ℃, add alkali...

Embodiment 3

[0079] a) Grafting reaction

[0080] Consistent with that described in Production Example 2, but itaconic acid becomes 0.5mol maleic acid, and other materials and reaction conditions remain unchanged.

[0081] b) Free radical polymerization

[0082] Then add a certain amount of distilled water and a little catalyst to the highly viscous reaction mixture, lower the temperature to 80-95°C, and simultaneously titrate the monomer solution (containing 51.5g sodium p-styrene sulfonate) and the ammonium persulfate initiator solution , 90min dripping, and heat preservation reaction 3h, natural cooling to below 40 ℃, add alkali and obtain bright brown red transparent solution, its pH value is 8.5 (solid content 37.8%), weight average molecular weight is 37400.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com