Printing head screw rod device suitable for coarse aggregate concrete 3D printing

A print head and concrete technology, applied in the field of 3D printing, can solve the problems of large volume, difficult to control and use, and low fault tolerance of eccentric crankshaft pumps, and achieve the effects of reasonable structure, increased use range, and improved uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

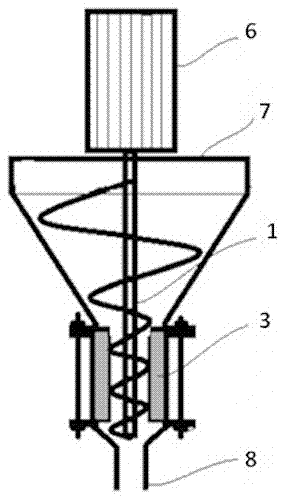

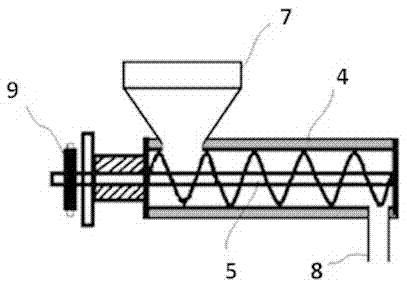

[0024] A printing head screw device suitable for 3D printing of coarse aggregate concrete of the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings:

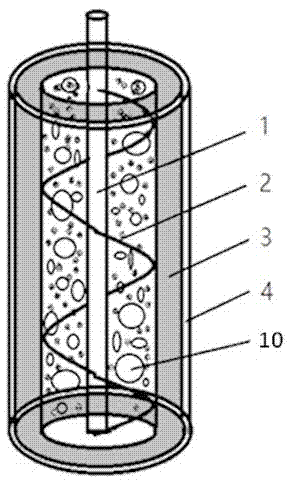

[0025] A structural schematic diagram of a print head screw device, such as figure 1 As shown, it includes a stator 4 and a rotor 5, the rotor 5 is arranged inside the stator 4, and it includes a straight rod 1 and a helical blade 2, and the helical blade 2 is evenly distributed on the straight rod 1; the stator 4 is a steel pipe and a An assembly of the flexible sleeve 3 , the flexible sleeve 3 is arranged between the helical blade 2 and the steel pipe, and the helical blade 2 on the rotor 5 is closely combined with the flexible sleeve 3 on the stator 4 .

[0026] When extruding printed concrete, there will be no extrusion pressure loss between the screw blade 2 and the flexible sleeve 3, which effectively ensures the uniformity of the extruded material.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com