Continuity testing method of cement mortar for 3D (Three Dimensional) printing of building

A 3D printing and continuity technology, which is applied in flow characteristics, measuring devices, instruments, etc., can solve the problems that there is no continuity test method, and the continuity of architectural 3D printing materials cannot be tested completely and accurately, so as to achieve the convenience of the test process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

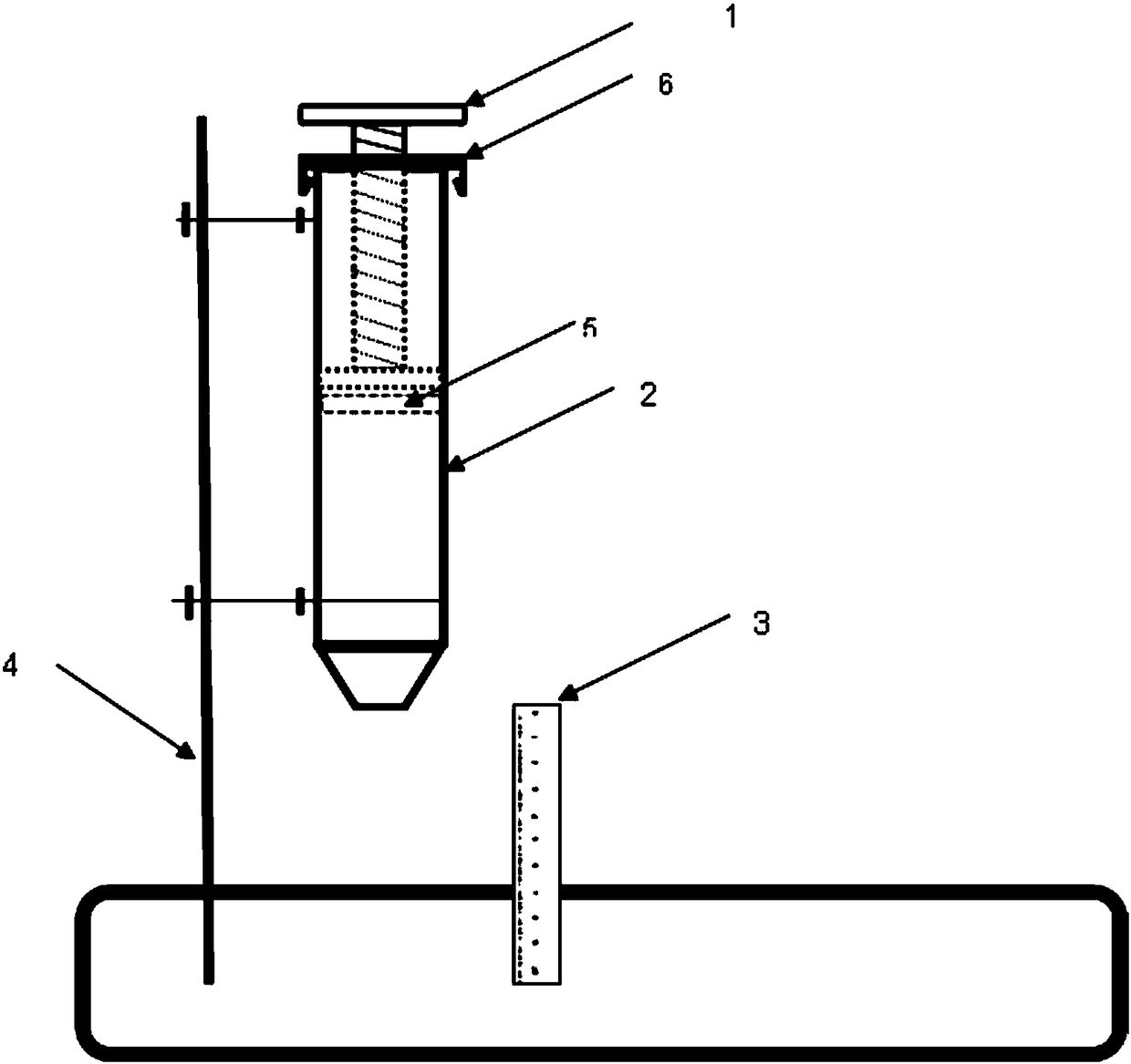

[0021] The present invention is a continuity test method for building 3D printing cement mortar. The present invention will be further described below in conjunction with examples: figure 1 It is a structural schematic diagram of a specific example of the present invention, which mainly includes a push rod 1 , an extrusion barrel 2 , a ruler 3 , a fixing bracket 4 , a gasket 5 and a rear cover 6 . The rod part of the push rod 1 is a screw rod, which can form a set of screw driving device with the back cover. The piston at the lower end is made of rubber, the diameter is equal to the inner diameter of the extrusion cylinder, and can move freely in the extrusion cylinder. The push rod 1 and the extrusion barrel 2 can be made of hard plastic, stainless steel metal material or aluminum metal material, and the gasket 5 is made of wool material.

[0022] The upper body of the extrusion barrel 2 is 55mm, and the extrusion port at the lower end is a circle with a diameter of 20mm. Ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com