Quantitative detection device and method for the extrusion performance of 3D printed mortar

A 3D printing and quantitative detection technology, applied in the field of architectural 3D printing materials, can solve the problems of unable to detect the continuity of printing materials, unable to reflect the pressure of 3D printing mortar, unable to reflect the pressure changes, etc., to achieve real-time detection. Good, wide range of application, easy to operate

Inactive Publication Date: 2019-09-17

HUAZHONG UNIV OF SCI & TECH

View PDF11 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0008] A device and method for testing the workability of 3D printing mortar is reported in the patent document "3D Printing Construction Mortar Workability Test Device and Application" (Application No.: CN 104297103 A), which can detect 3D printing mortar The extrusion speed and operating time under a certain pressure, but cannot detect the continuity of the extrusion process of the printed material, nor can it re

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

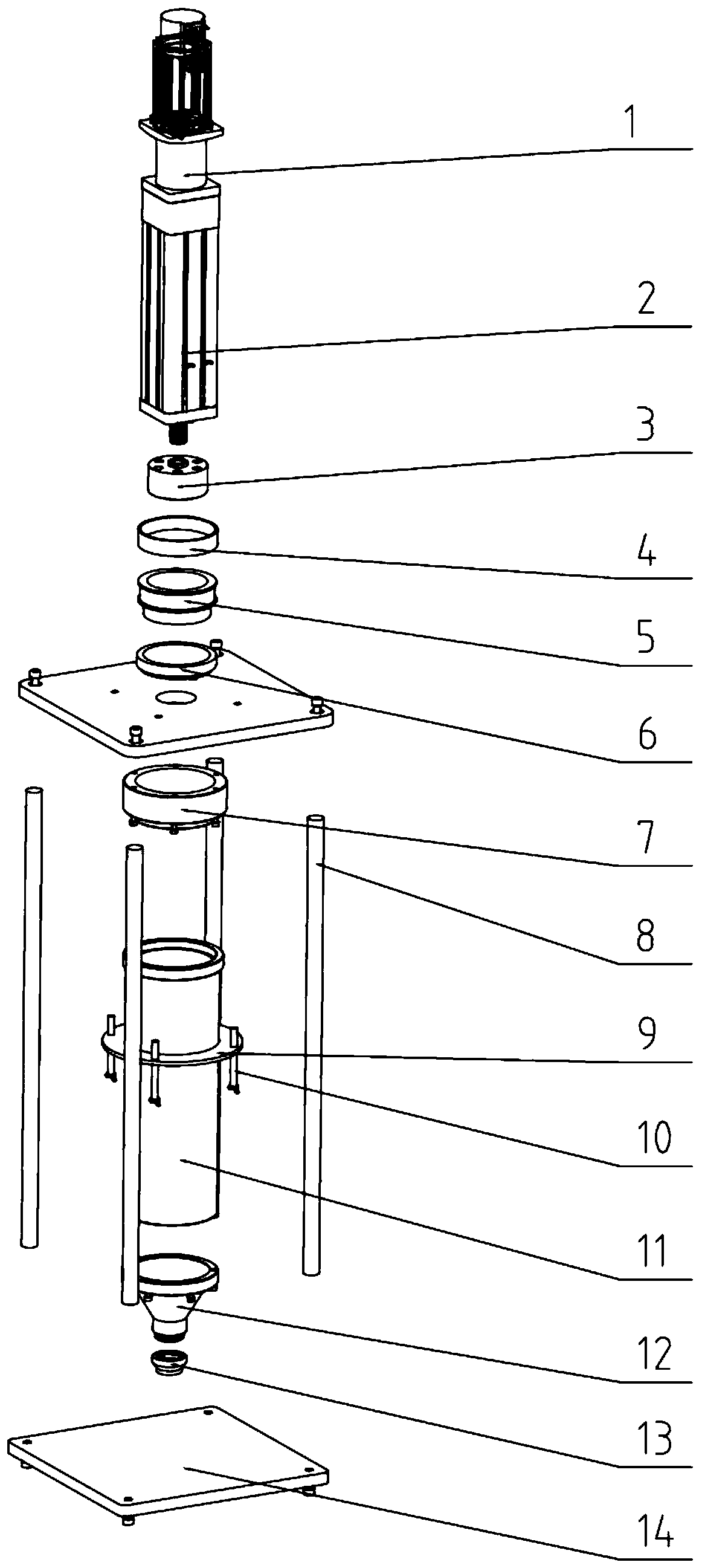

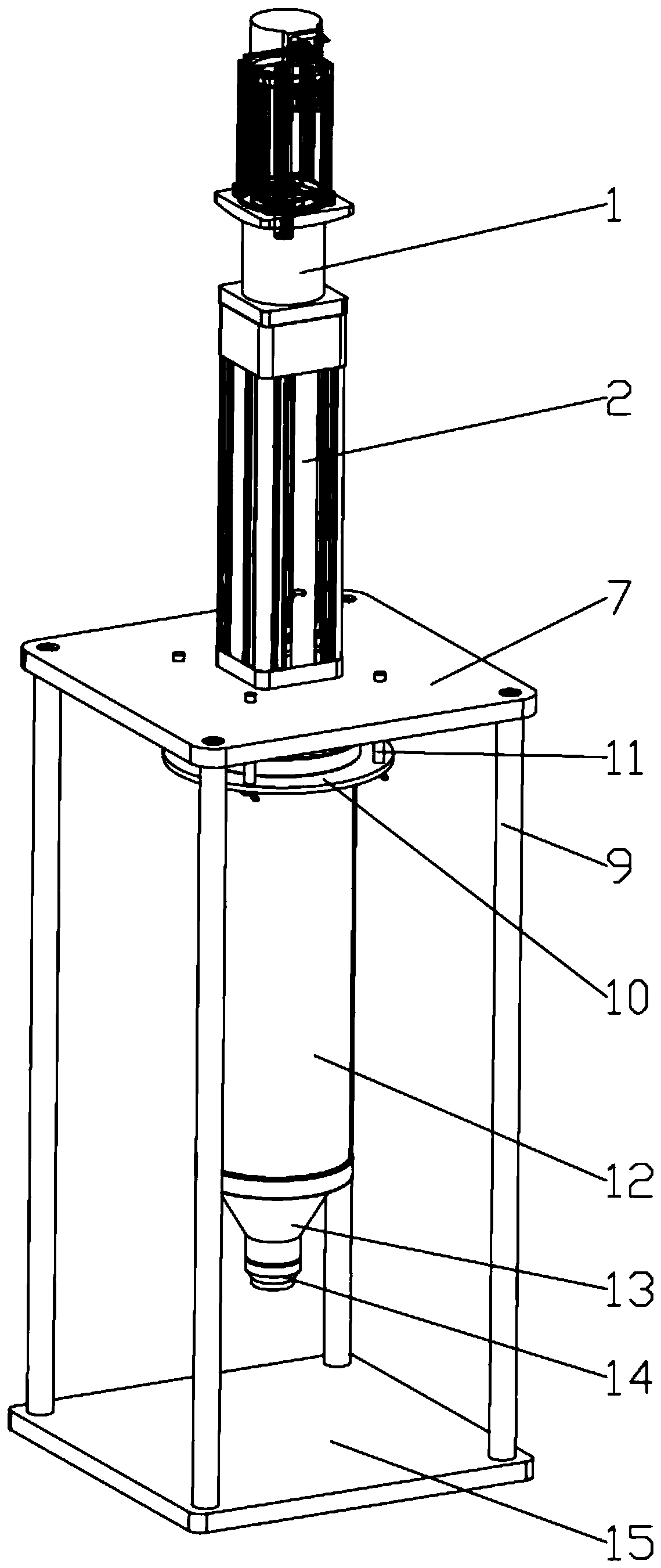

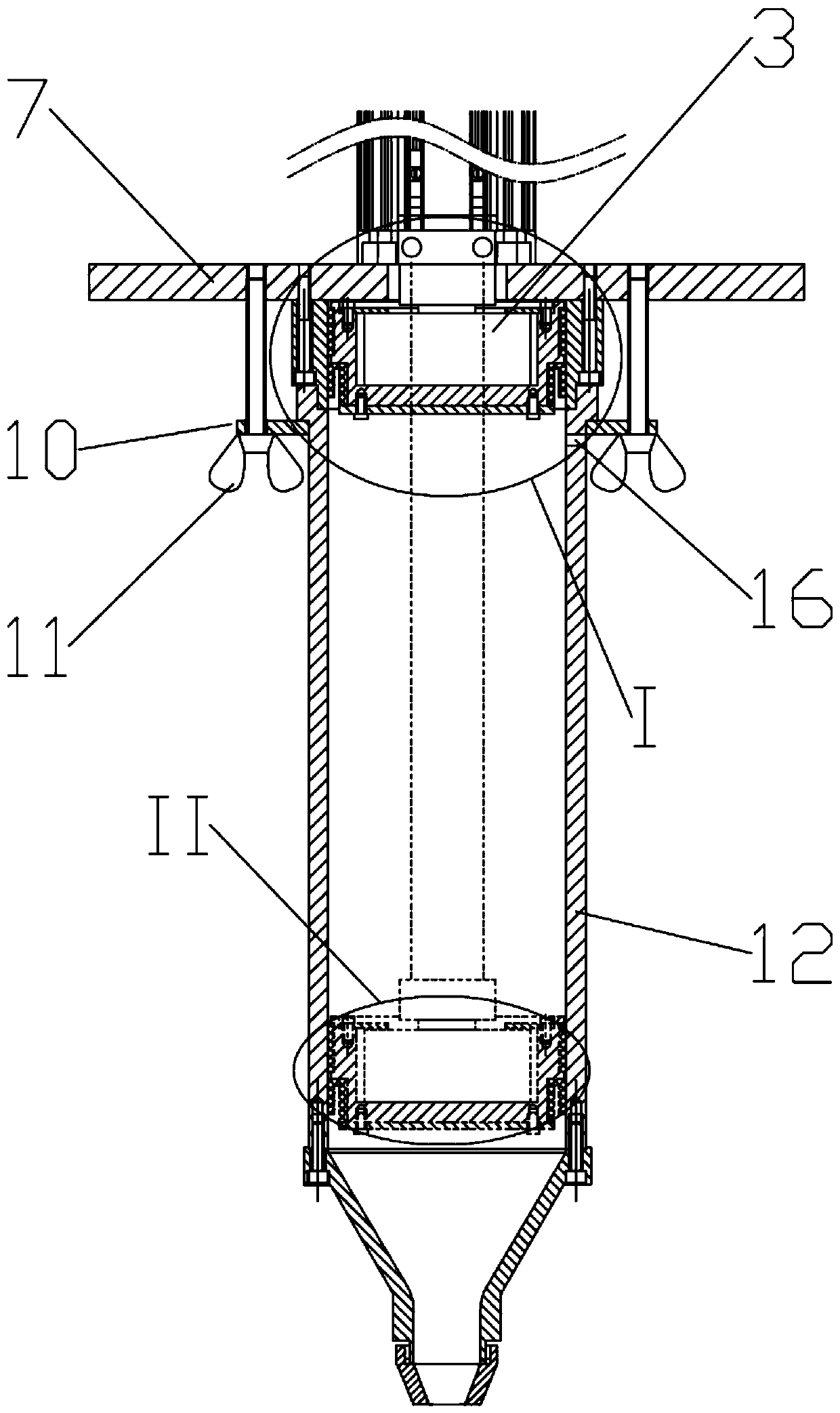

The invention discloses a quantitative detection device and method for the extrusion performance of 3D printed mortar, and belongs to the field of building 3D printing materials. The device comprises a servo motor, an electric cylinder, a pressure sensor, a piston, a base, a material cylinder, a nozzle and a ruler; by controlling the extrusion speed and the extrusion caliber, a feedback pressure generated by the mortar is measured in real time to quantitatively represent the extrusion performance of a material; and meanwhile, the extrusion continuity of the material is quantitatively represented by detecting the continuous extrusion length of the mortar. The detection method and device can accurately reflect the deformability, the liquidity and the feedback pressure of the material during extrusion; a scientific and effective method is provided for quantitative characterization of the extrusion performance of the 3D printing materials; and parameters and bases are provided for design and optimization of the materials.

Description

technical field [0001] The invention belongs to the field of architectural 3D printing materials, and more specifically relates to a quantitative detection device and method for the extrusion performance of 3D printing mortar. Background technique [0002] Architectural 3D printing technology is a new fast and low-pollution construction technology produced by combining 3D printing technology with building material technology. Modernization is of great significance. Currently, the most popular 3D printing construction technologies include contour technology and D-shape. This invention is mainly aimed at the contour technology printing method. Its main principle is to use a computer to perform 3D modeling and segmentation of target components or buildings to produce 3D information, and then The prepared cement-based building material mixture is passed through the extrusion device, and according to the set program, through mechanical control, it is extruded through the nozzle ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N11/00

CPCG01N11/00

Inventor 蔡礼雄刘文黎徐捷易幸存谢定坤

Owner HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com