Cement-based material used for building 3D (three-dimensional) printing

A cement-based material and 3D printing technology, applied in the field of cement-based materials, can solve the problems of high brittleness, decreased strength of cement-based materials, and lack of scale for 3D printing, achieving the effects of low cost, good shaping, and high early strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

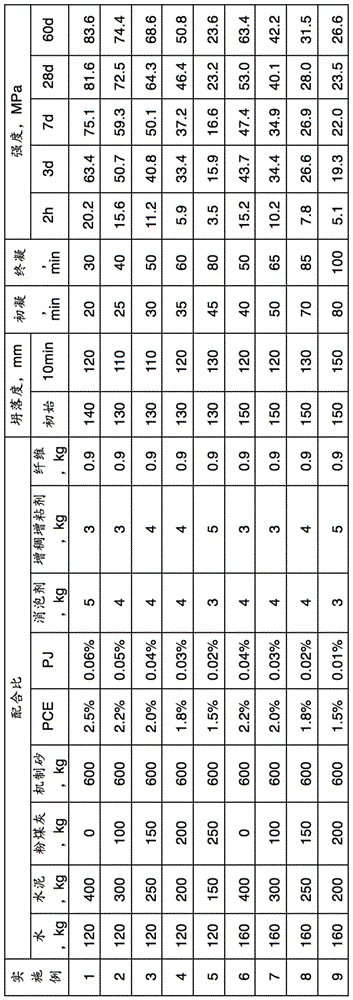

[0019] Below in conjunction with embodiment do specific explanation.

[0020] The raw materials used in the following examples are as follows:

[0021] Cement: Sulphoaluminate cement, grade 42.5, produced by Shandong Qufu Zhonglian Cement Co., Ltd.; its 3d strength is 36.4MPa, 28d strength is 46.8MPa, and 60d strength is 48.8MPa.

[0022] Fly ash: Class II ash, produced by Feixian Power Generation Co., Ltd. in Linyi City, Shandong;

[0023] Machine-made sand: use a certain type of machine-made sand produced by Zaozhuang Jinshan Machinery Co., Ltd., with a particle size of 0.075mm-5mm;

[0024] Defoamer: tributyl phosphate, analytically pure, produced by Liqiang Factory in Panyu, Guangzhou;

[0025] Thickening and viscosifying agent: 108 glue, powder, produced by Beijing Wanji Jianye Group Co., Ltd.;

[0026] Polypropylene staple fiber (hereinafter referred to as fiber): length 6mm, produced by Langfang Xiangyu Chemical Co., Ltd.;

[0027] Polycarboxylate superplasticizer P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com