Portal type building 3D printer achieving integral and alternate lifting

A 3D printer, gantry-type technology, applied in the field of 3D printing in construction engineering, can solve the problems of separate disassembly, design, manufacturing, and cost impact, limited printer design length, etc., to simplify the mechanism and structure, and reduce costs. , Conducive to the effect of scientific and technological achievements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

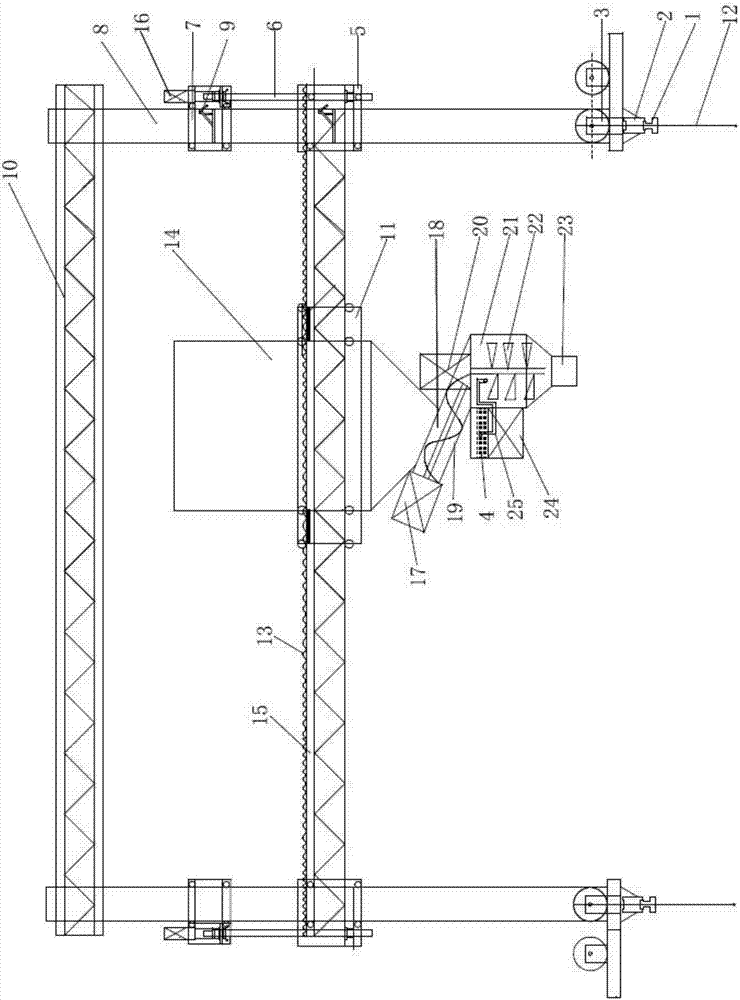

[0016] Attached below figure 1 The present invention is described further:

[0017] The gantry-type overall alternate lifting construction 3D printer includes a support frame 10, and the two ends of the support frame 10 are connected to the Z-axis slide rails 8 to form a gantry-type support structure. The bottom of the Z-axis slide rails 8 slides through the Y-axis drive mechanism and the guide wheels 2 Connected to the Y-axis track 1, the Z-axis slide rail 8 is slidably connected with a trolley a7 and a trolley b5 provided with a locking mechanism 9, the trolley a7 is connected above the trolley b5 through an alternate lifting mechanism, and the trolley b5 Connect the two ends of the X-axis slide rail 15, the sliding trolley 11 is driven by the X-axis drive motor to slide and connect the X-axis slide rail 15, the slide trolley 11 is connected to the printing mechanism, the Y-axis drive mechanism, the X-axis drive motor, the alternate lifting mechanism, the printing mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com