Workpiece positioning device of three-dimensional laser cutting device

A cutting equipment, three-dimensional laser technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve problems such as difficulty in ensuring workpiece cutting accuracy, hidden dangers in production safety, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

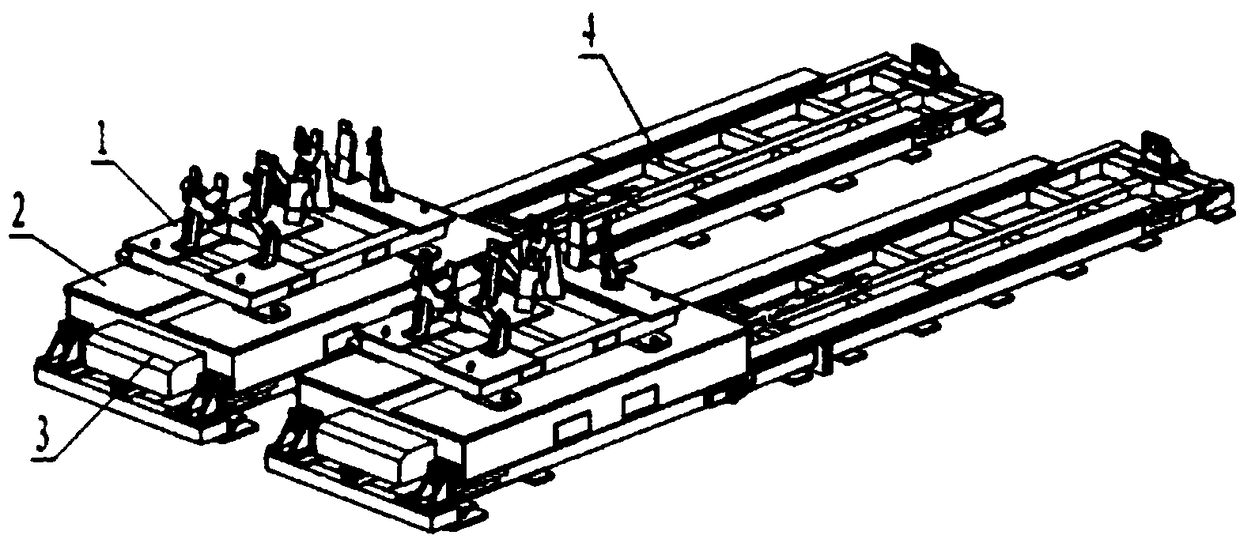

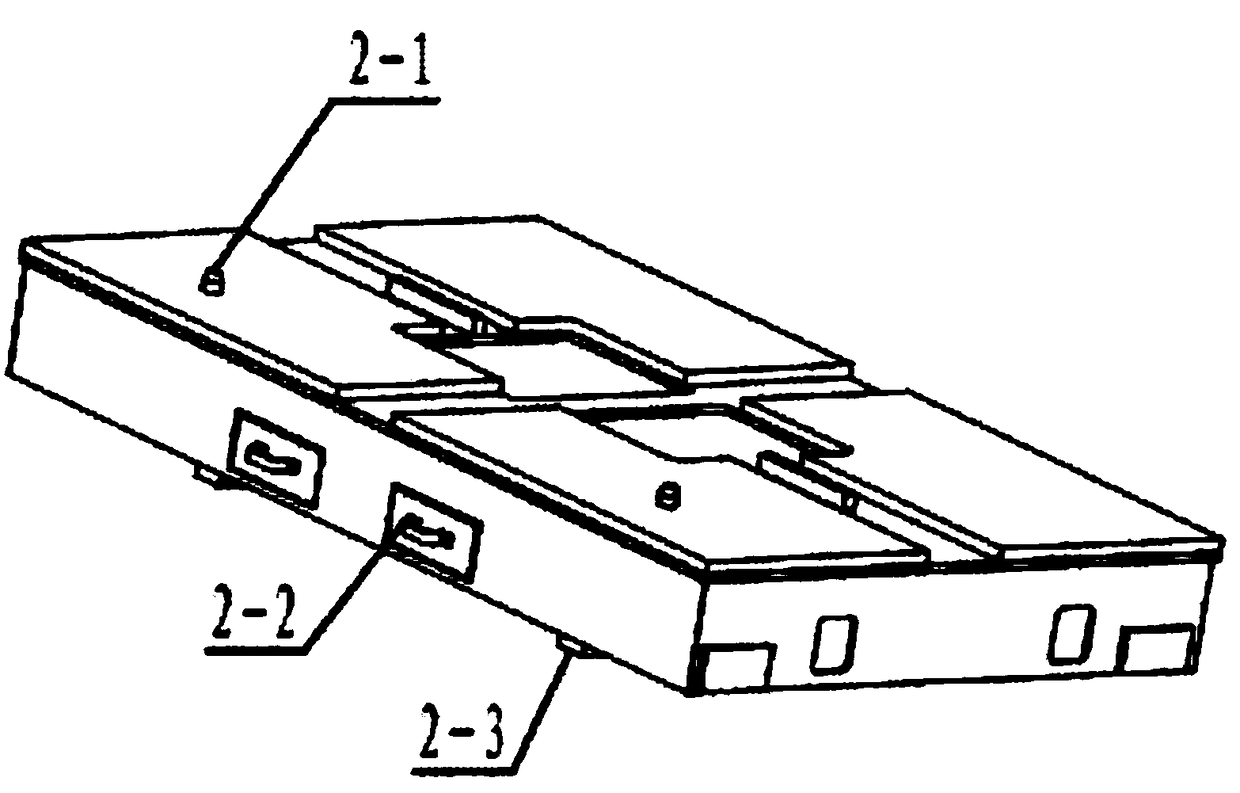

[0024] see figure 1 , the present invention includes two parts arranged left and right, wherein each part is composed of a combined fixture 1, a mobile vehicle body 2, a drive mechanism 3 and a base 4, the combined fixture 1 is installed on the mobile vehicle body 2, and the mobile vehicle body 2 is assembled with the base 4, and the driving mechanism 3 is installed between the mobile vehicle body 1 and the base 4.

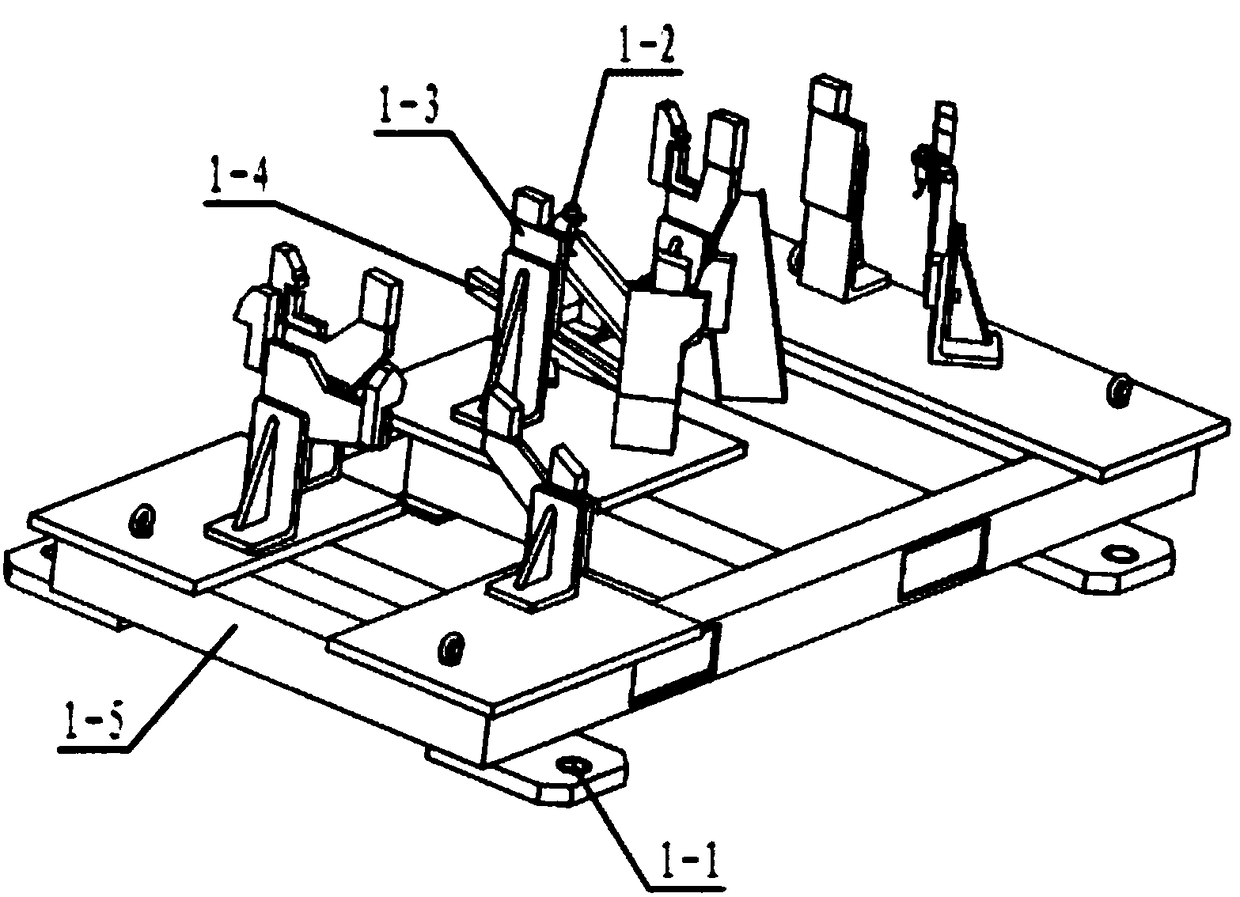

[0025] see figure 1 , figure 2 The combination fixture 1 of the present invention includes a fixture base 1-5, a workpiece connection support assembly 1-3 and a material receiving plate 1-4, the fixture base 1-5 is a hollow structure, and the workpiece connection support assembly 1-3 and the connection plate The material plate 1-4 is fixed on the fixture base 1-5, a proximity switch 1-2 is provided on the workpiece connection support assembly 1-3, positioning pin holes 1-1 are set at the four corners of the fixture base 1-5, and the combination The fixture 1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com