A three-dimensional vibration isolation device

A vibration isolation, three-dimensional technology, applied in the direction of shock absorber, shock absorber, shockproof, etc., can solve the problems of small horizontal stiffness, damage, swing, etc., and achieve the effect of excellent vibration isolation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

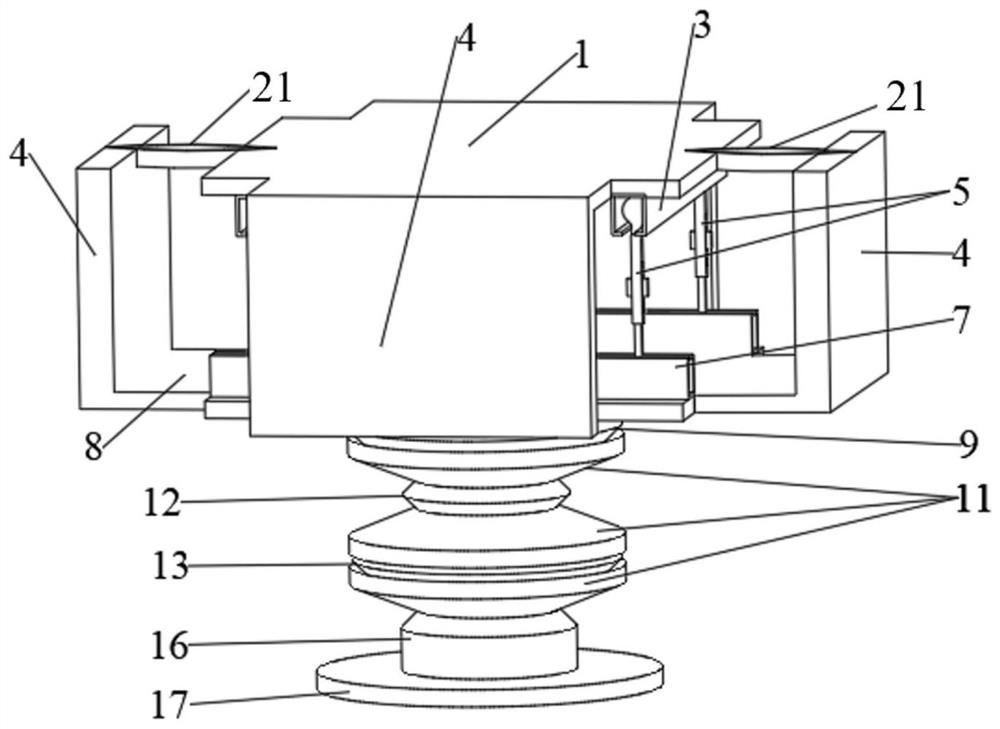

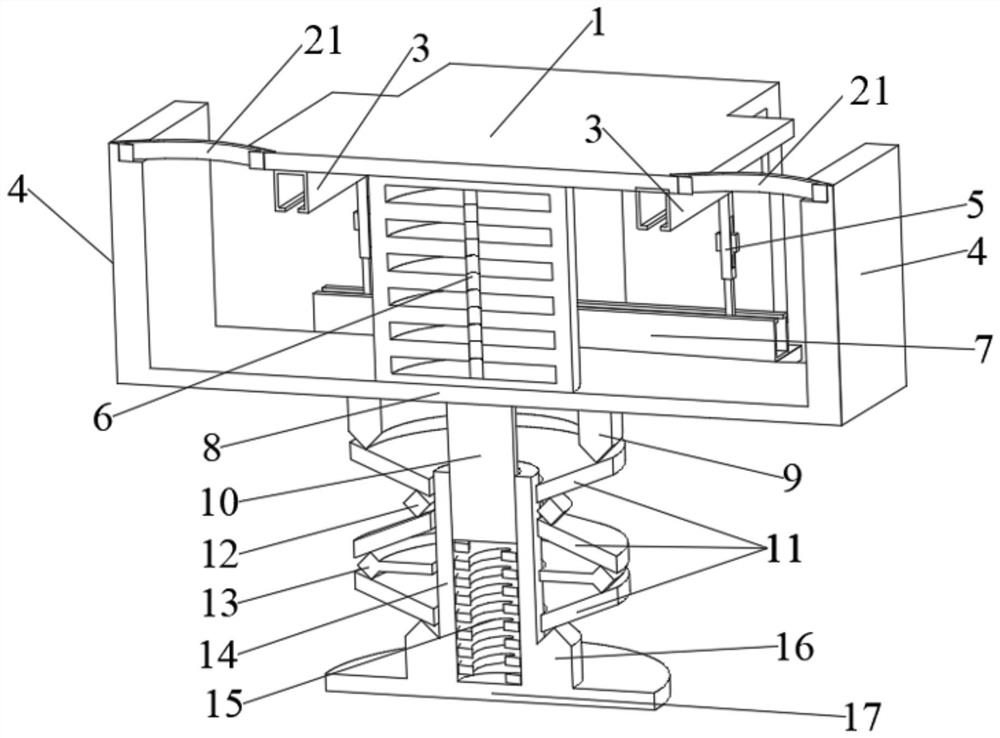

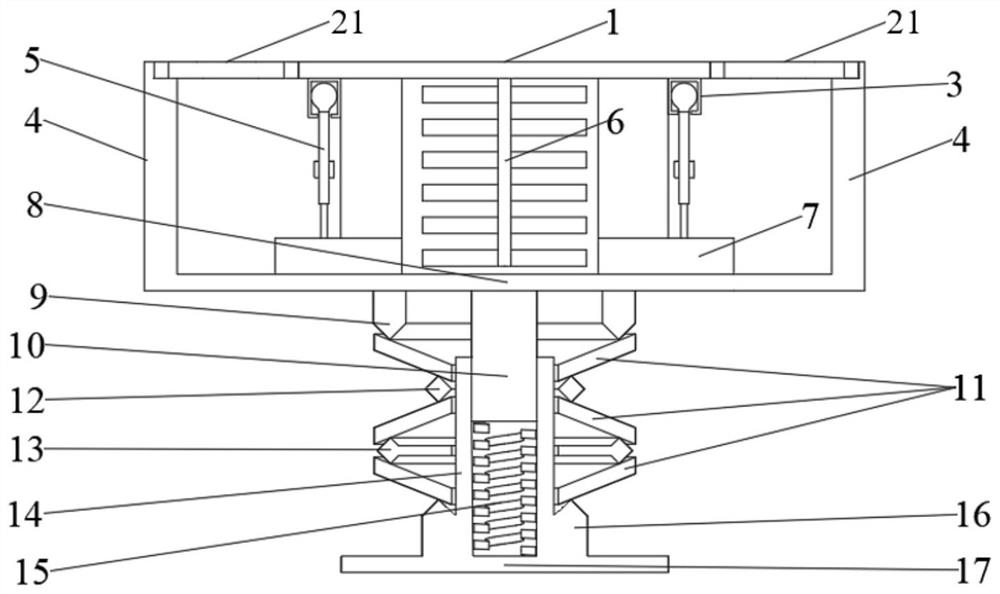

[0030] Such as Figure 1-9 as shown,

[0031] A three-dimensional vibration isolation device, characterized in that: comprising

[0032] 1. The support system, including an upper connecting plate 1, an intermediate connecting plate 8, a lower connecting plate 17, and a peripheral plate 4; The middle connecting plate 8 is connected to form a frame body; the upper connecting plate 1 is used to place the vibration-isolated object; the lower connecting plate 17 is connected to the foundation;

[0033] 2. Horizontal vibration isolation device, including rubber bearing 6, guide rail, slide block 5, Euler beam (first Euler beam 21, second Euler beam 22);

[0034] The rubber support 6 is arranged in the center of the entire horizontal vibration isolation device, its upper end surface is connected with the upper connection plate 1, and its lower end surface is connected with the middle connection plate 8. The rubber support 6 provides horizontal restoring force for the entire device,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com