High-rise building 3D printing device connected with steel platform and construction method thereof

A technology of 3D printing and high-rise buildings, which is applied in the direction of construction, building structure, and on-site preparation of building components. It can solve the problems of not being able to meet the rapid construction of high-rise buildings, achieve high construction efficiency, improve printing efficiency, and be widely used. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

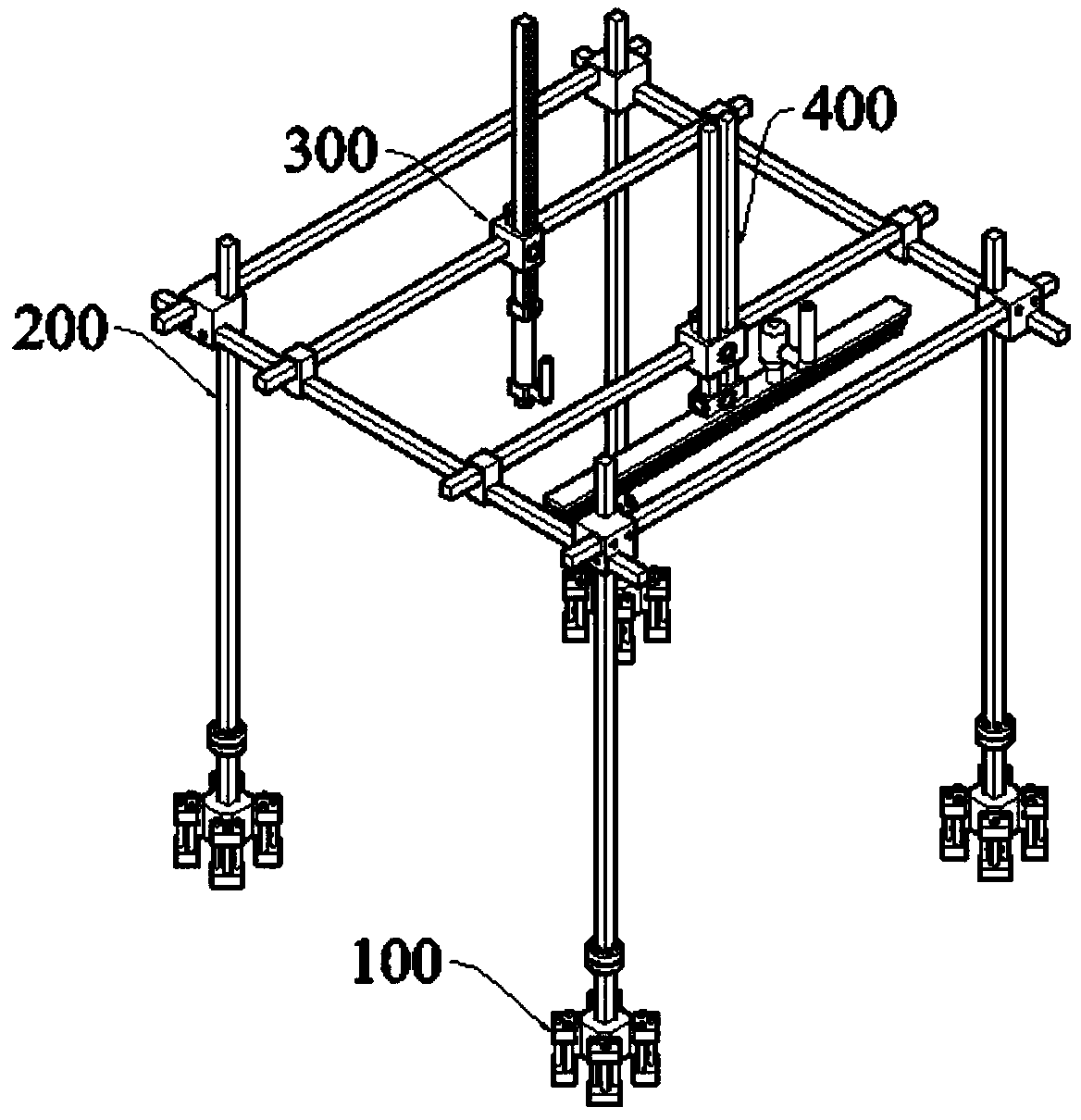

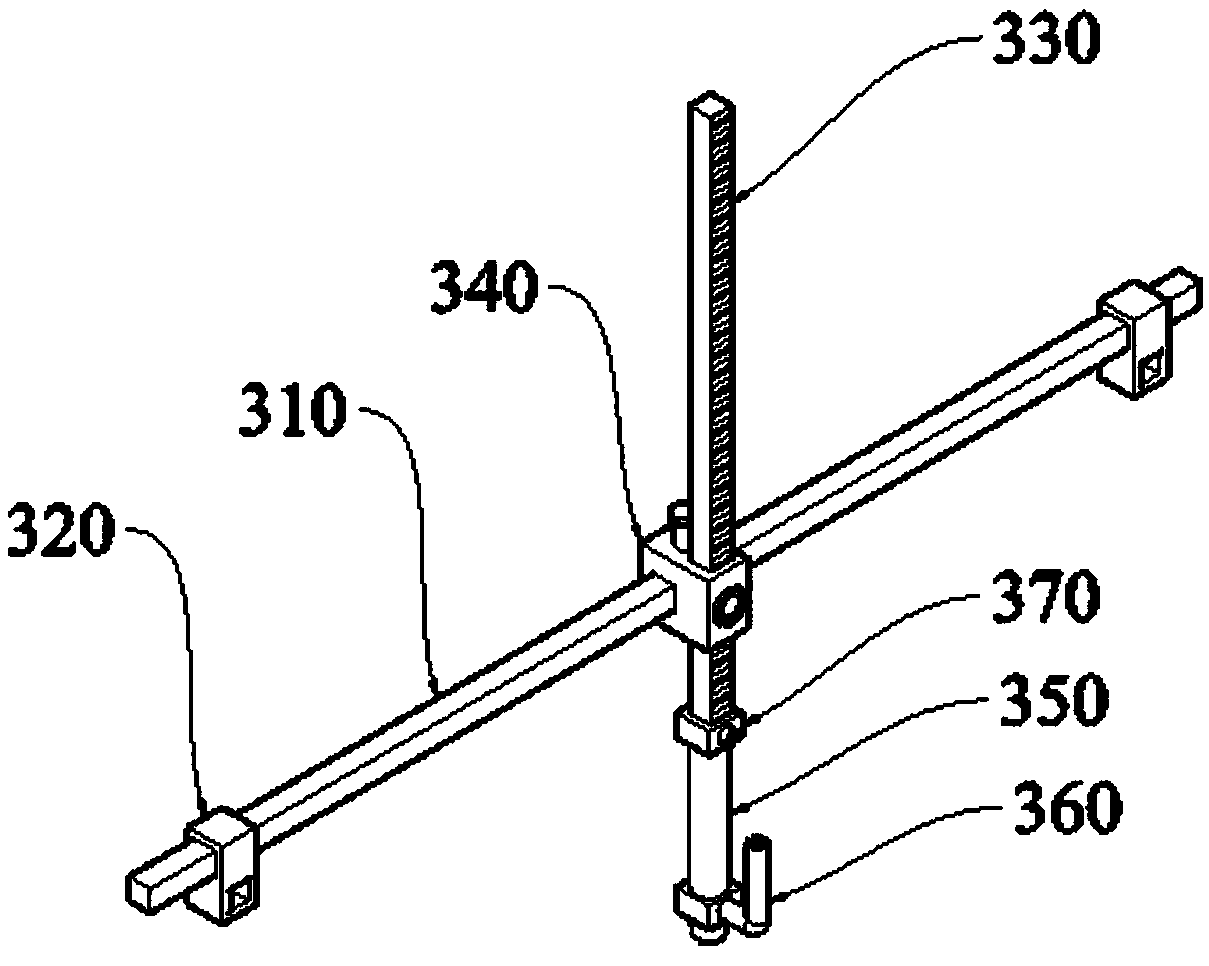

[0043] see Figure 1 to Figure 6 As shown, the present embodiment provides a high-rise building 3D printing device connected with a steel platform, which will be combined below Figure 1 to Figure 6 The gist of the present invention is further described.

[0044] Such as figure 1 As shown, the high-rise building 3D printing device connected to the steel platform includes a platform connection base 100 , a driving guide frame body 200 , a main structure 3D printing mechanism 300 , and a decorative structure 3D printing mechanism 400 . The platform connection base 100 is detachably connected to the steel platform (not shown), and the bottom of the driving guide frame body 200 is fixed on the steel platform. The driving guide frame body 200 is provided with a main structure 3D printing mechanism 300, a decorative structure 3D printing The mechanism 400 can simultaneously realize the 3D printing of the main structure and decorative structure of the building.

[0045] Such as ...

Embodiment 2

[0055] This embodiment provides a construction method of a high-rise building 3D printing device connected with a steel platform, combined below Figure 1 to Figure 6 As shown, the construction method is further explained. This construction method comprises the steps:

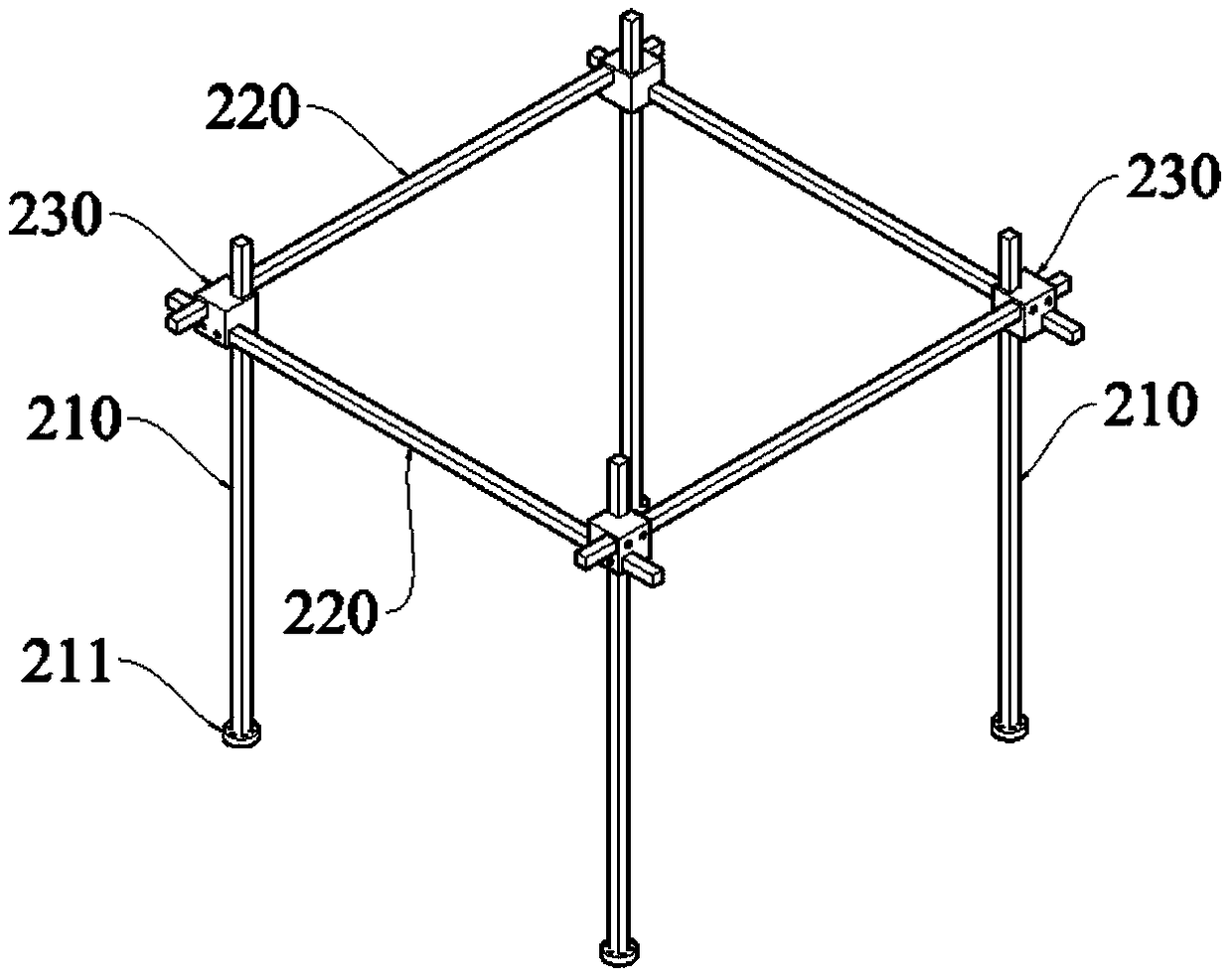

[0056]Step 1. Fixedly connect the platform connection base 100 in the first embodiment to the steel platform, and then fix the vertical guide rail 210 on the platform connection base 100 to realize the rigid connection between the 3D printing device and the steel platform. During the first construction, the driving guide frame body 200, the main structure 3D printing mechanism 300, and the decorative structure 3D printing mechanism 400 can be assembled on the steel platform, and then spliced into a 3D printing device; , only need to remove the connection between the platform connection base 100 and the steel platform, set the platform connection base 100 at the place to be installed, then move the 3D printin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com