Control method of walking-type building 3D printing process

A 3D printing and process control technology, applied in the direction of manufacturing tools, additive processing, auxiliary molding equipment, etc., can solve the problems of complex movement control, high labor intensity, inconvenient application, etc., to improve printing quality, reduce labor intensity, and shape small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

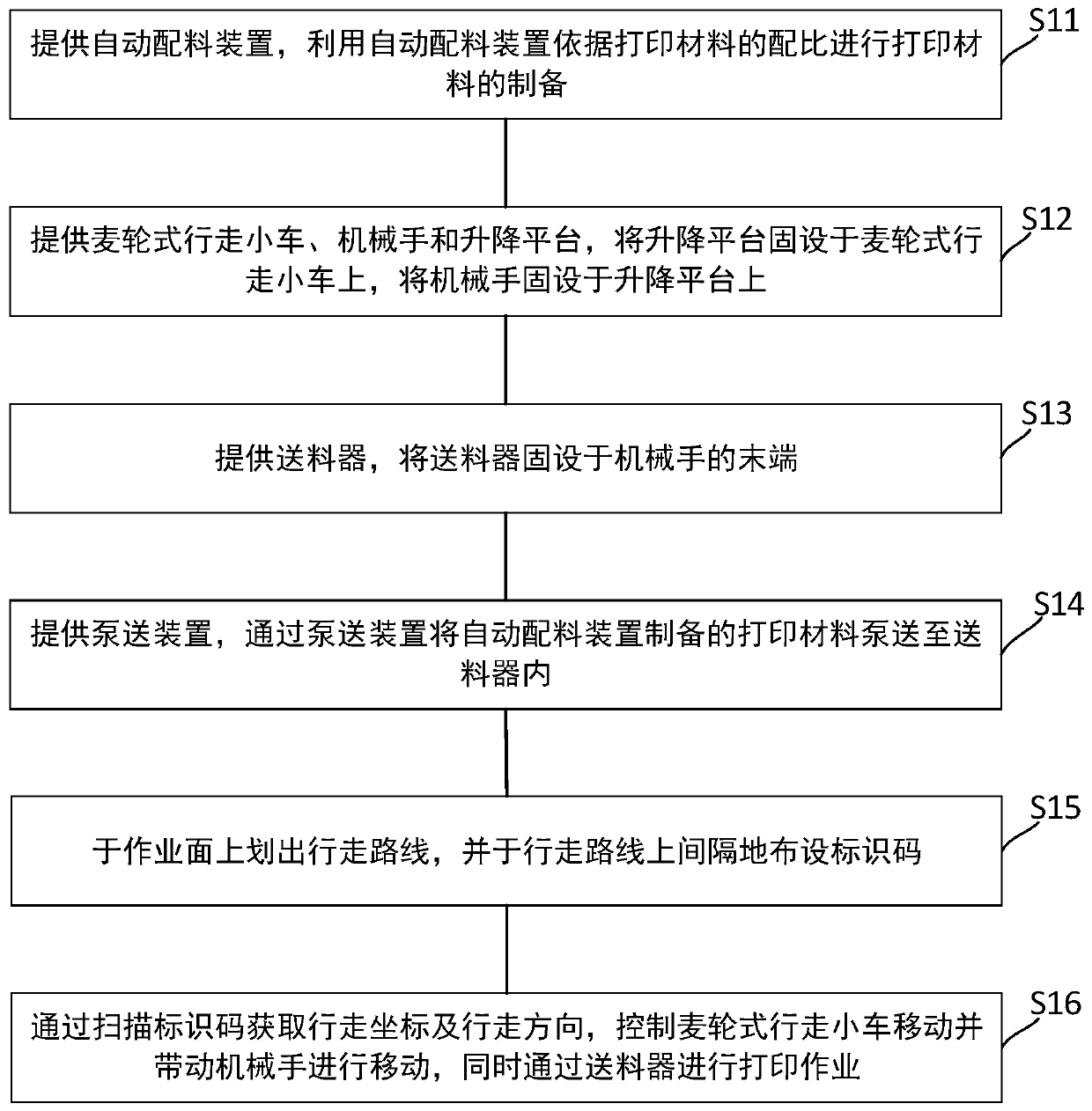

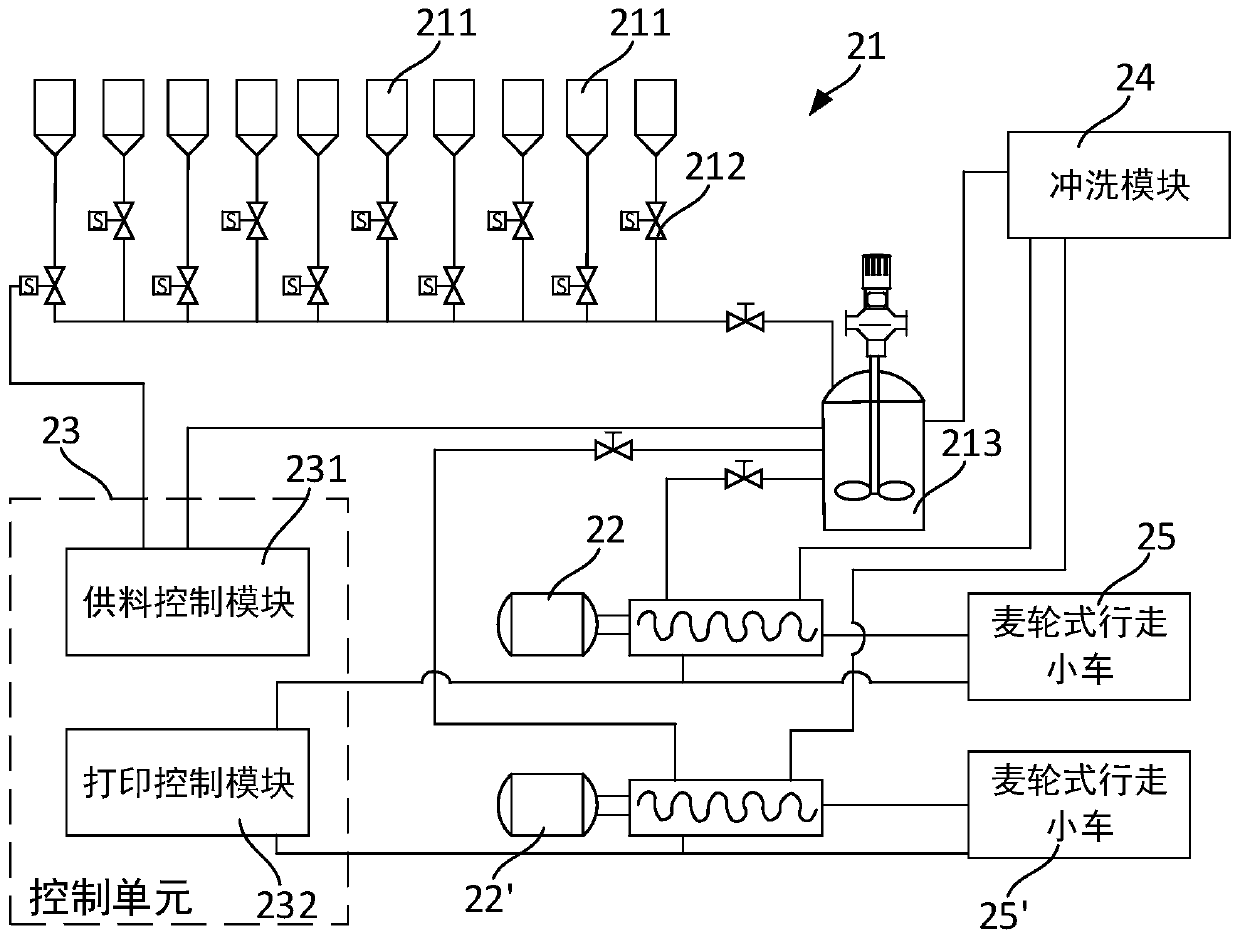

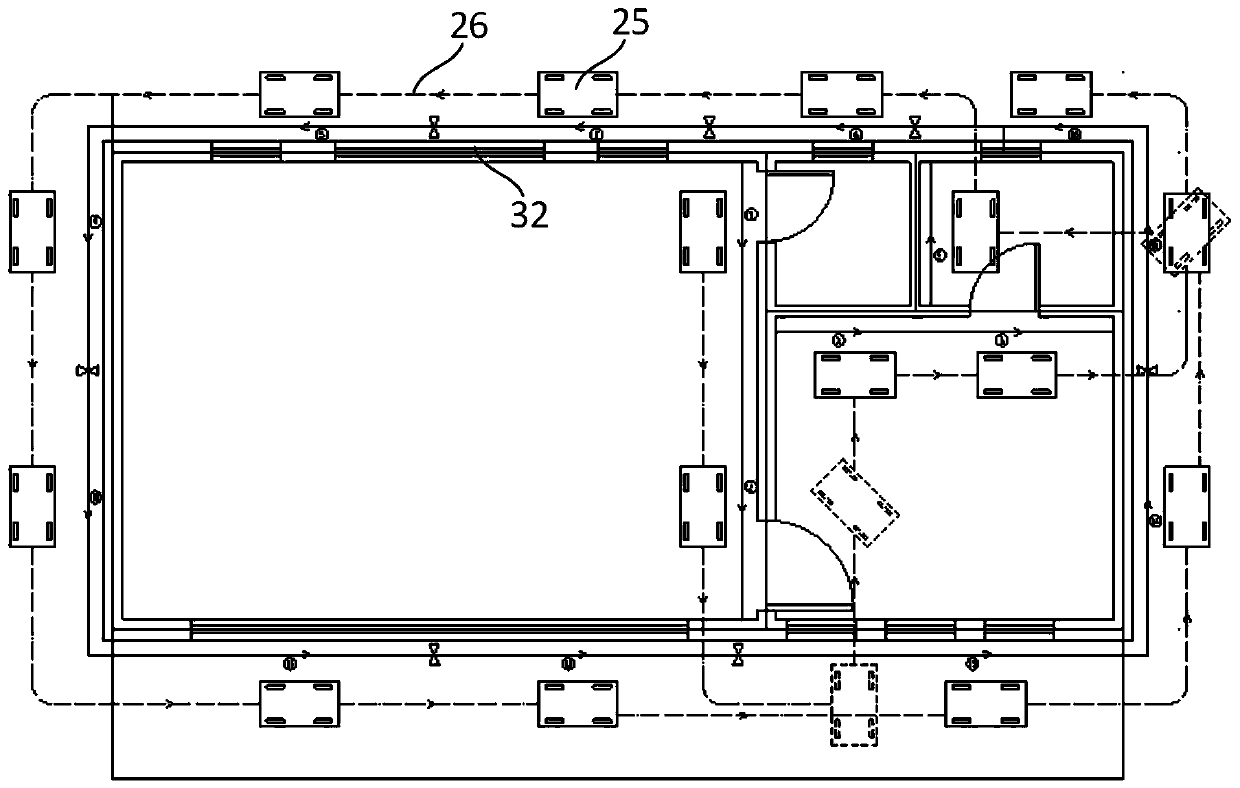

[0051] refer to figure 1 , the present invention provides a walking-type architectural 3D printing process control system and method, which adopts an automatic weighing and automatic batching automatic batching device to realize the intelligentization of powder weighing, batching, and stirring links, and realizes full automation. Humanized material supply reduces labor intensity and environmental pollution. The wheat wheel-type walking trolley is used to drive the manipulator to move, which can realize intelligent movement in any direction in the plane, without setting the turning radius, high positioning accuracy, sideways movement at any angle, and stable and reliable operation. The manipulator adopts a 6-axis manipulator, which can meet multi-dimensional printing requirements and achieve curved surface and multi-dimensional printing effects...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com