Shield tail sealing grease and preparation method thereof

A shield tail sealing and grease sealing technology, applied in the field of grease, can solve problems such as the gap between adhesion and impermeability, insufficient adhesion and weak impermeability, and achieve high impermeability and enhance adhesion. and stability, the effect of stable product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

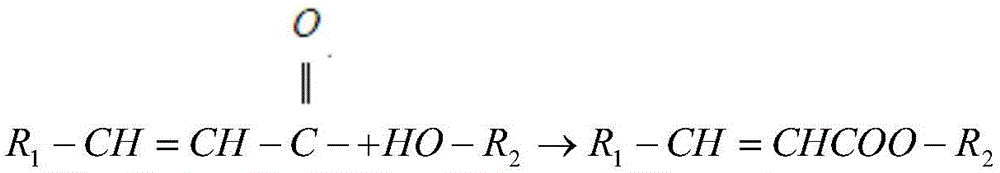

Method used

Image

Examples

Embodiment 1

[0022] Shield tail sealing grease in the present embodiment, its component and mass percent are as follows: 30% hydraulic oil; 6% petroleum resin; 19% calcium base grease; 5% alkyd resin; 30% calcium carbonate; 5% wood fiber, 5% glass fiber, the fiber length is 0.5 ~ 4mm.

[0023] Preparation method: Put the hydraulic oil into the kneader, start stirring and heat up to about 80°C, then put in petroleum resin, stir until the petroleum resin is completely dissolved, stop stirring and heating; after cooling to 50-60°C, put in calcium-based grease, alcohol Acid resin and calcium carbonate, stir and knead until uniform; finally add wood fiber and glass fiber, stir and knead for 1 to 2 hours.

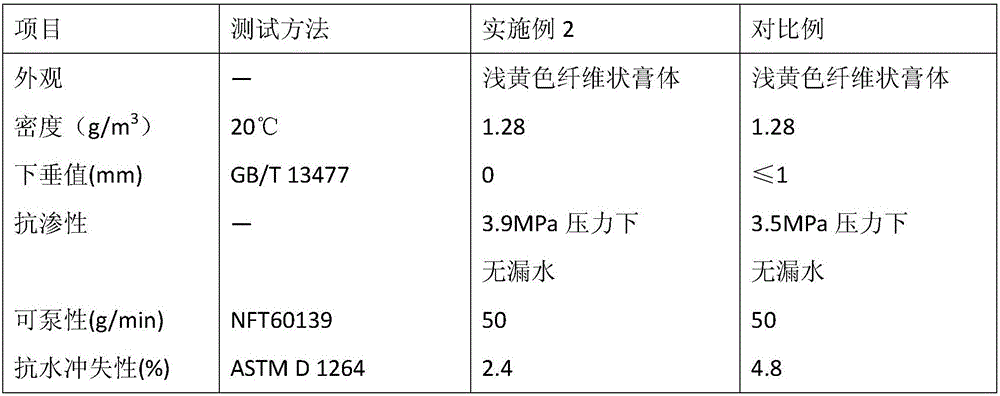

Embodiment 2

[0025] Shield tail sealing grease in the present embodiment, its component and mass percentage are as follows: 20% corn oil; 8% rosin resin; 20% lithium base grease; 4% polybutyl acrylate; 40% bentonite; 5% asbestos fiber, fiber length is 0.5 ~ 4mm.

[0026] Preparation method: Put corn oil into the kneader, start stirring and heat up to about 80°C, then put in rosin resin, stir until the rosin resin is completely dissolved, stop stirring and heating; after cooling to 50-60°C, put in lithium base grease, polyester Butyl acrylate and bentonite, stir and knead until uniform; finally add synthetic fiber and asbestos fiber, stir and knead for 1 to 2 hours.

Embodiment 3

[0028] The shield tail sealing grease in the present embodiment has the following components and mass percentages: 15% linseed oil; 7% polyisobutylene; 20% lithium-based grease; 5% polyurethane; 45% kaolin; Paoyrite fiber, the fiber length is 0.5-4mm.

[0029] Preparation method: Put linseed oil into the kneader, start stirring and heat up to about 80°C, then put in polyisobutylene, stir until the polyisobutylene is completely dissolved, stop stirring and heating; after cooling to 50-60°C, put in lithium-based grease, polyurethane in turn and kaolin, stir and knead until uniform; then put in bamboo fiber and sepiolite fiber, stir and knead for 1 to 2 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com