High-performance reinforced mortar suitable for thick-layer spraying and preparation method thereof

A high-performance, mortar technology, applied in the field of high-strength concrete structure reinforcement building materials, can solve the problems of aggravating the corrosion of steel bars inside the mortar, inability to carry out thick layer spraying, unreasonable configuration methods, etc., to achieve reduced bulk density, excellent hanging performance, and avoid shrinkage cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

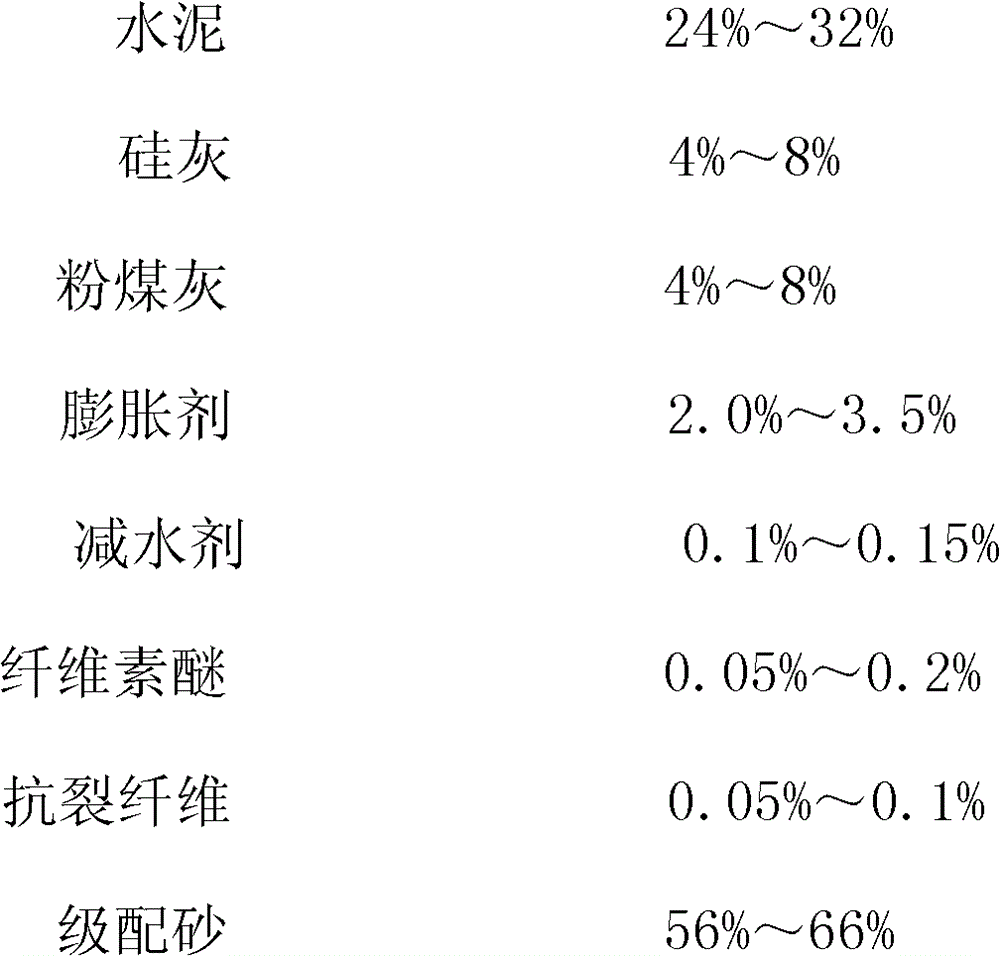

[0026] The mass ratio of each component of high-performance reinforced mortar is as follows:

[0027]

[0028]

[0029] The specific steps of high-performance reinforcement mortar configuration in this example are as follows: first, pre-mix the additives in the formula except cement and graded sand according to the ratio to form an additive mixture, and then fully mix the additive mixture with cement and graded sand 1. Package to form dry powder. After transporting to the construction site, add water according to 12.5% of the dry powder mass and fully stir, then use a screw mortar jetting machine for construction. The thickness of the mortar layer can reach 40mm in a single spray.

Embodiment 2

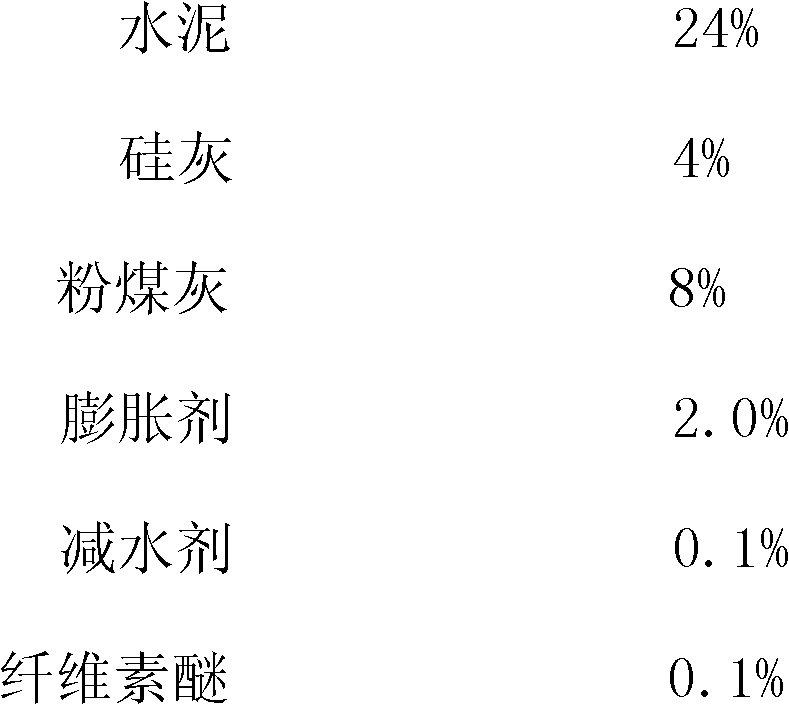

[0031] The mass ratio of each component of high-performance reinforced mortar is as follows:

[0032]

[0033] The specific steps of high-performance reinforcement mortar configuration in this example are as follows: first, pre-mix the additives in the formula except cement and graded sand according to the ratio to form an additive mixture, and then fully mix the additive mixture with cement and graded sand 1. Package to form dry powder. After transporting to the construction site, add water according to 14% of the dry powder mass and fully stir, then use screw mortar jetting machine for construction. The thickness of the mortar layer can reach 40mm in a single spray.

[0034] According to the method of the above two embodiments, and select representative similar products on the market as a typical comparison sample, under the same conditions of construction, maintenance and testing methods, the performance data obtained are described as follows:

[0035]

[0036] It can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com