A radial single-end double-expansion grouting bolt for tunnels in broken rock formations

A technology for grouting bolts and tunnels, which is applied in the installation of bolts, mining equipment, earthwork drilling, etc., can solve the problems of high construction cost and long time, and achieve the effect of flexible layout, flexible layout and convenient construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

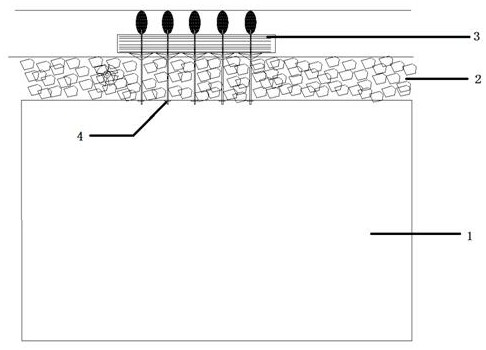

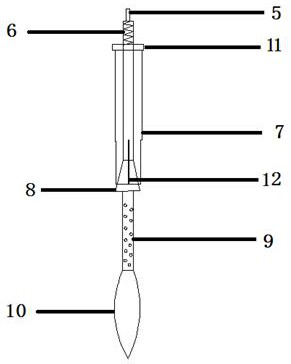

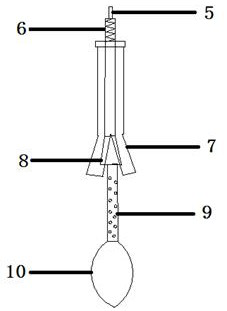

[0018] Example: A radial single-ended two-way expansion grouting bolt for a broken rock formation tunnel

[0019] Such as Figure 1-3 As shown, the radial single-ended two-way expansion grouting anchor rod of the broken rock formation tunnel includes the outer steel pipe 7 of the anchor rod, the hollow threaded steel pipe 6, the conical jacking head 8, the grouting bag 10 and the bolt 11; Embedded in the outer steel pipe 7, the bolt 11 is threadedly connected with the hollow threaded steel pipe 6, and is arranged above the outer steel pipe 7, the length of the outer steel pipe 7 is shorter than the hollow threaded steel pipe 6, and the bottom of the outer steel pipe 7 is provided with a gap 12, hollow The middle part of the threaded steel pipe 6 is provided with a conical jacking head 8, the diameter of the outer edge of the conical jacking head 8 is larger than the outer diameter of the outer steel pipe 7, the bottom of the hollow threaded steel pipe 6 is connected with a gro...

Embodiment approach

[0022] Insert the grouting pipe 5 into the hollow threaded steel pipe 6, and inject grout into the bottom grouting bag 10 to squeeze the surrounding rocks; after the grout in the grouting bag 10 is stable, pull out the grouting pipe 5, The hollow threaded steel pipe 6 is grouted, and the cement mortar is filled into the broken rock formation through the grouting hole 9 to complete the bolt reinforcement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com