Formula of foam extinguishing agent containing biosurfactant and preparation method for foam extinguishing agent

A foam fire-extinguishing agent and biological surface technology, which is applied in the formulation and preparation of foam fire-extinguishing agent, can solve the problem of foam fire-extinguishing agent easily polluting the environment and save time, and achieve excellent spreading and adhesion ability, improved storage stability, and improved fire-extinguishing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

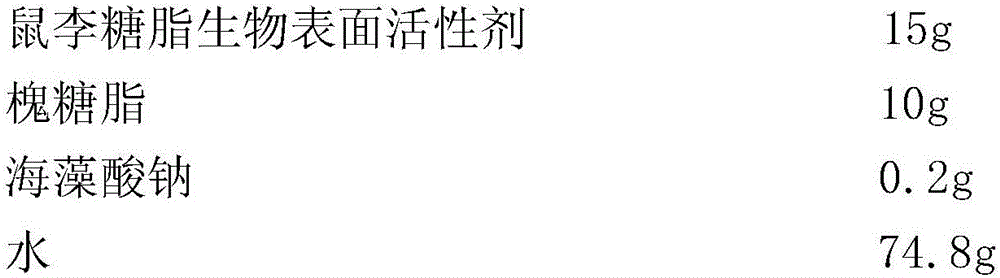

Embodiment 1

[0021]

[0022] First add 20% water into the reaction kettle equipped with a stirrer, stir slowly with a paddle stirrer, the stirring speed is 80rpm, slowly add 15% of rhamnolipid biosurfactant, and slowly add 10% sophorolipid after stirring evenly %, and continue until all the materials are stirred evenly, heat to 80°C in the reaction kettle, and cool to room temperature; add 0.2% sodium alginate to another 10% of water, stir to make it completely dissolved, then add it to the reaction kettle to make up The remaining 44.8% of water is stirred evenly, and the preparation is completed.

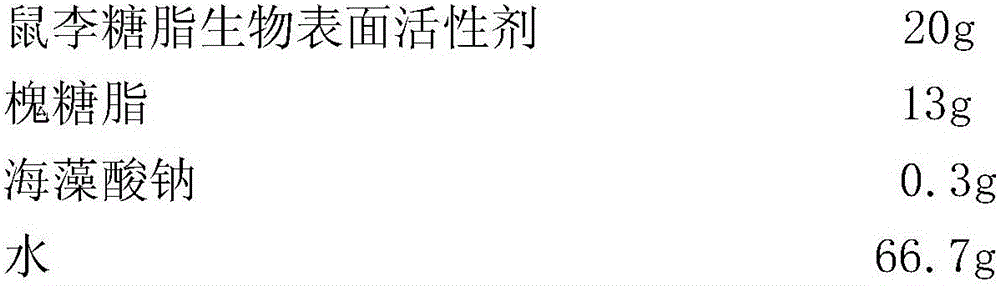

Embodiment 2

[0024]

[0025] First add 25% water into the reaction kettle equipped with a stirrer, stir slowly with a paddle stirrer, the stirring speed is 60rpm, slowly add 20% rhamnolipid biosurfactant, and slowly add sophorolipid 13 after stirring evenly %, and continue until all the materials are stirred evenly, heat to 80°C in the reaction kettle, and cool to room temperature; add 0.3% sodium alginate to another 10% of water, stir to make it completely dissolved, and then add it to the reaction kettle to make up The remaining 31.7% of water is stirred evenly, and the preparation is completed.

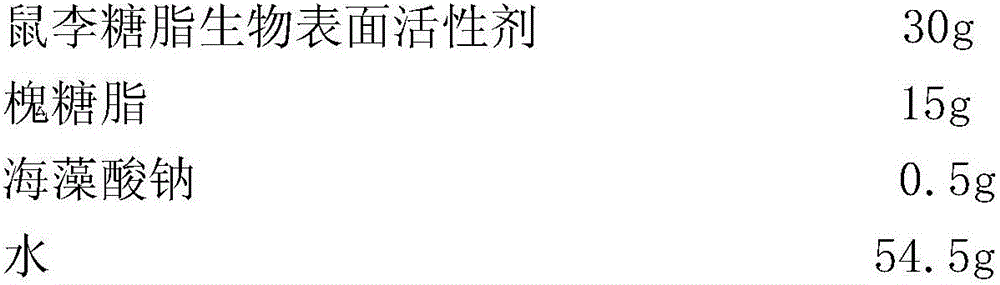

Embodiment 3

[0027]

[0028] First add 30% water into the reaction kettle equipped with a stirrer, stir slowly with a paddle stirrer, the stirring speed is 60rpm, slowly add 30% rhamnolipid biosurfactant, and slowly add 15% sophorolipid after stirring evenly. %, and continue until all the materials are stirred evenly, heat to 80°C in the reactor, and cool to room temperature; take another 15% of water and add 0.5% sodium alginate, stir to make it completely dissolved and then add it to the reactor to make up The remaining 9.5% of water is stirred evenly, and the preparation is completed.

[0029] The medicaments used in Examples 1-3 are all commercially available.

[0030] In the embodiment, rhamnolipid performance and safety performance test are shown in Table 1:

[0031] Table 1: Rhamnolipid performance and safety performance test

[0032]

[0033] The fire extinguishing agent concrete effect that above-mentioned embodiment 1-3 prepares sees the following table 2:

[0034] The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com