Ballastless track steel reinforced concrete pile-net construction method

A reinforced concrete and construction method technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problem of not being able to meet the requirements of ballastless track subgrade reinforcement, polluting the working surface and the surrounding environmental water system, multiple construction machinery and labor, etc. problems, to achieve the effect of preventing collapse and shrinkage, reducing construction machinery and labor, and meeting reinforcement requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

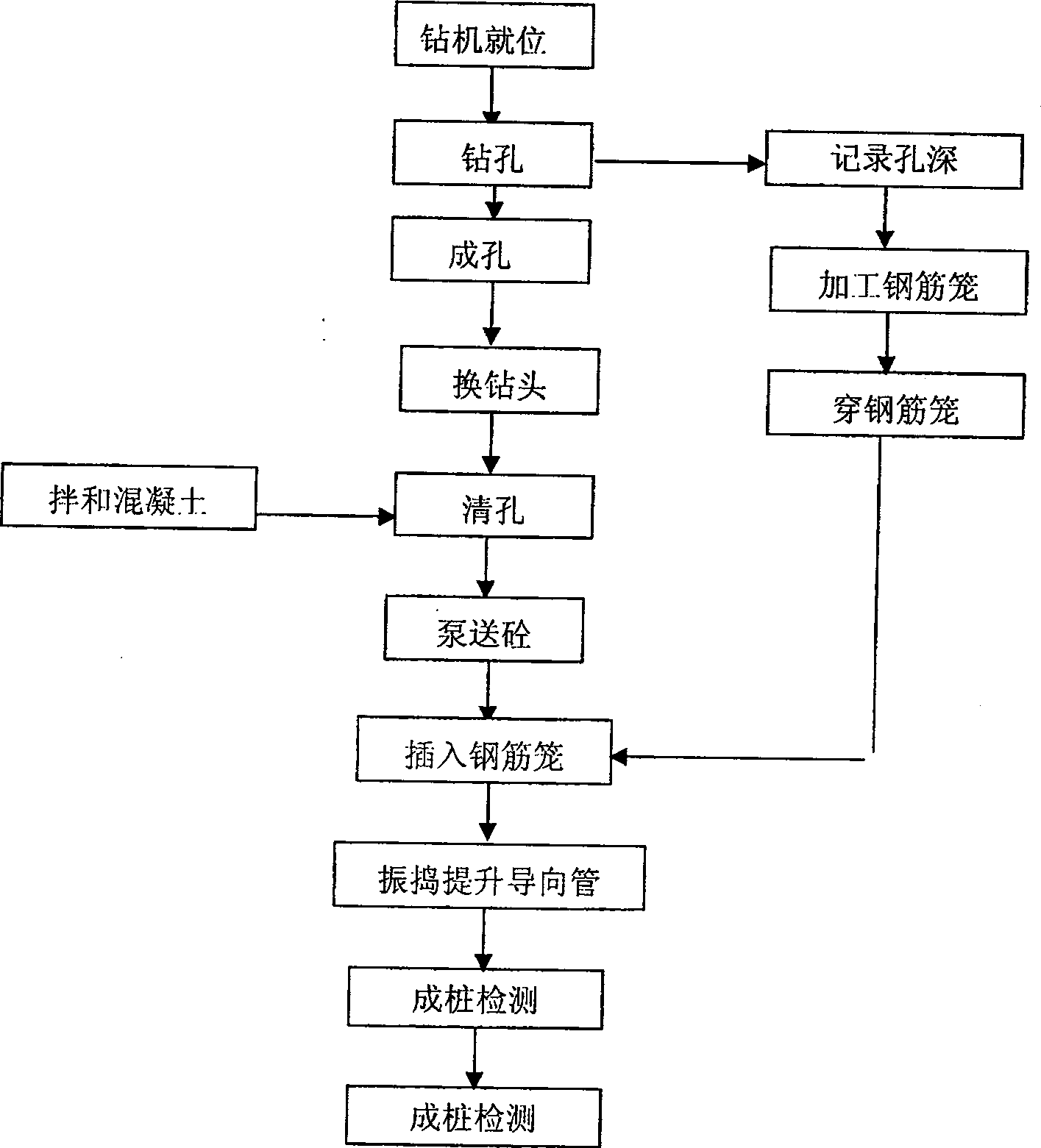

Method used

Image

Examples

Embodiment Construction

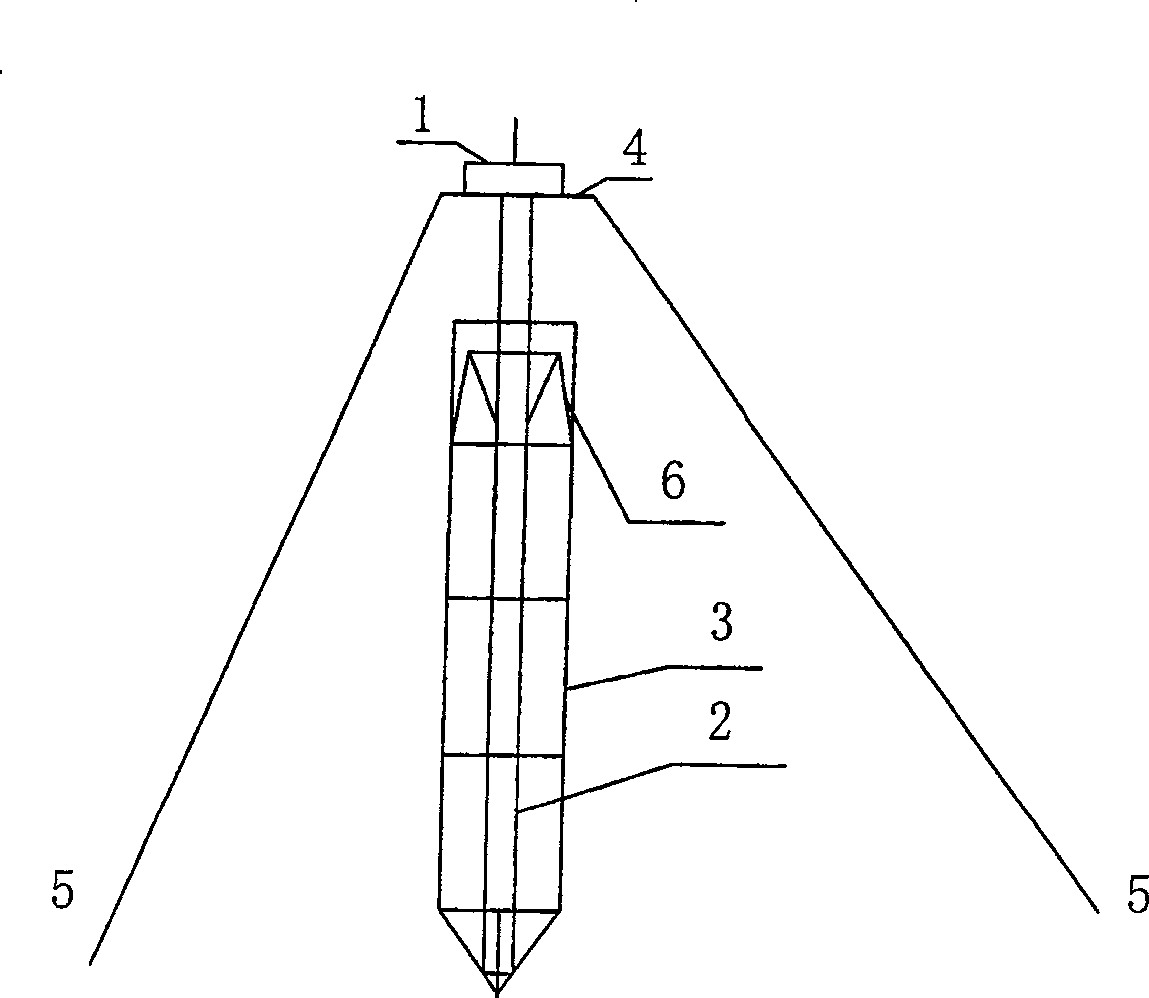

[0016] The comprehensive test section of the ballastless track of the Suiyu Railway was carried out on the basis of the Class I railway that has already started construction. Before the construction of the test section, part of the subgrade in the test section had been filled to a distance of 5-6m from the subgrade surface. In order to meet the technical requirements for the laying of the ballastless track For the already filled embankment, impact roller compaction is used for additional compaction, and then the reinforced concrete pile network structure is set up for foundation reinforcement, and the embankment is filled according to the technical standard of ballastless track subgrade.

[0017] 1. Construction preparation:

[0018] (1) In order to eliminate the negative friction effect of the filling soil after the pile network construction is completed, after the site is leveled before construction, the filled embankment is firstly compacted by impact rolling and compacted b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com