Offshore wind power duct rack grouting material and construction method thereof

A grouting material, offshore wind power technology, applied in the field of cement-based materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] The selection of component raw materials in the grouting material of embodiment 1

[0085] 1. Cement

[0086] 1.1 Cement 1: 52.5 grade ordinary Portland cement produced by Ningbo Conch Cement Co., Ltd. is used.

[0087] The performance index of cement 1 must meet the quality requirements of ordinary Portland cement with a strength grade of 52.5 specified in the standard GB175-2007 "General Portland Cement". Tests were carried out on the performance indicators of cement 1, such as mortar strength, stability, fineness, and setting time, and the test results of the performance indicators are shown in Table 1. It can be seen from Table 1 that the stability of the material is qualified. In addition, the measured density of cement is 3.15g / cm 3 .

[0088] 1.2 Cement 2: Use grade 52.5 sulfoaluminate cement produced by Tangshan Liujiu Cement Co., Ltd.

[0089] The performance index of cement 2 should meet the quality requirements of 52.5-grade sulphoaluminate cement specif...

Embodiment 2

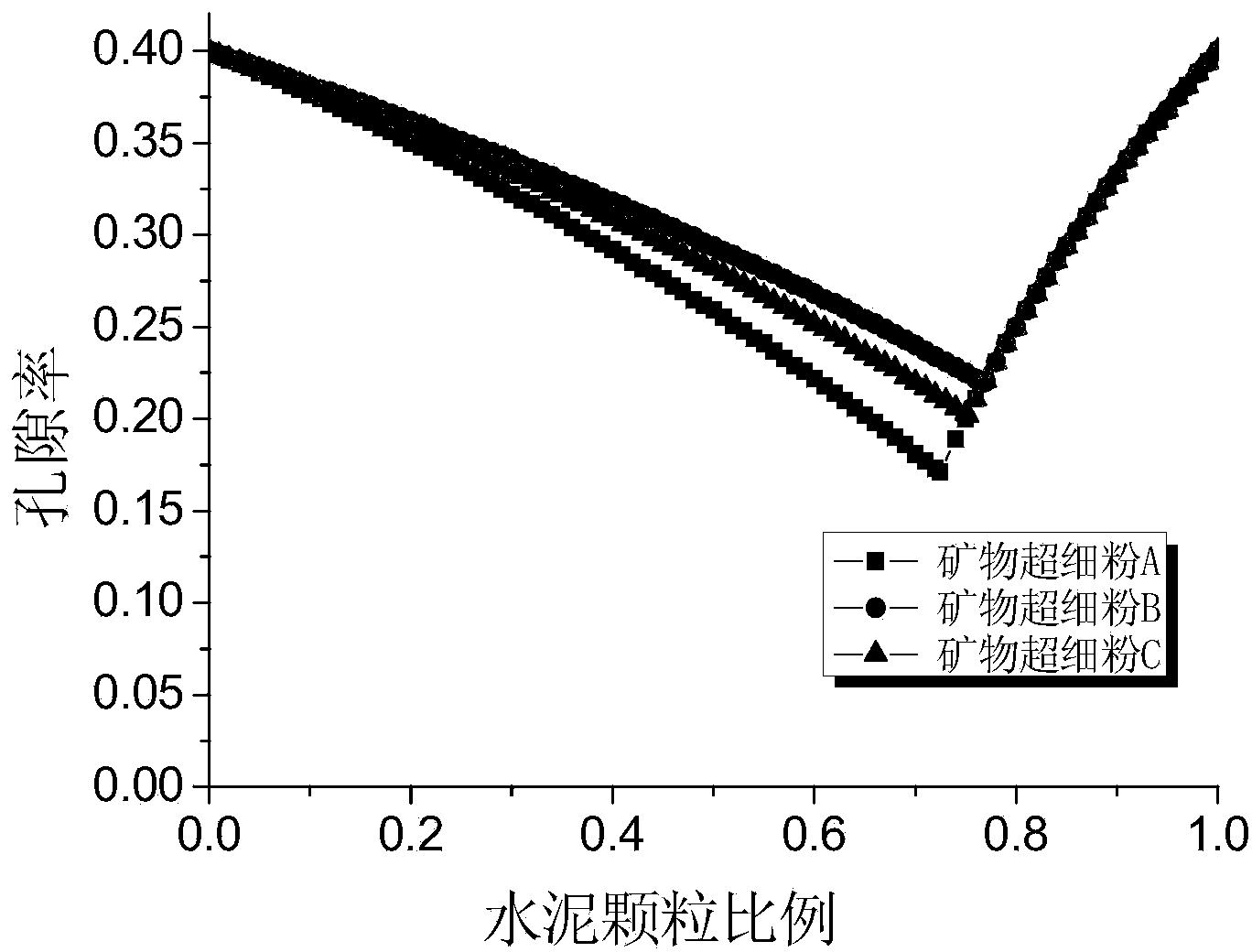

[0134] The composite mineral superfine powder compact filling test of embodiment 2 grouting material

[0135] The invention adopts composite mineral superfine powder, which is composed of silicon powder, superfine fly ash and superfine slag powder. In order to explore the compact filling effect of composite mineral superfine powder on cement, different composite mineral superfine powders were mixed according to the design ratio, and the pure cement, the composite cementitious material mixed with composite mineral superfine powder and the compound mineral superfine powder were designed respectively. Composite gelling material 2 Three kinds of gelling materials (see Table 10). Table 11 is the comparison of water consumption and workability of three different cementitious material grouting materials, and Table 12 is the comparison of mechanical properties and durability of three different cementitious material grouting materials. The fluidity test is carried out in accordance wi...

Embodiment 3

[0146] The preparation of embodiment 3 grouting material 1

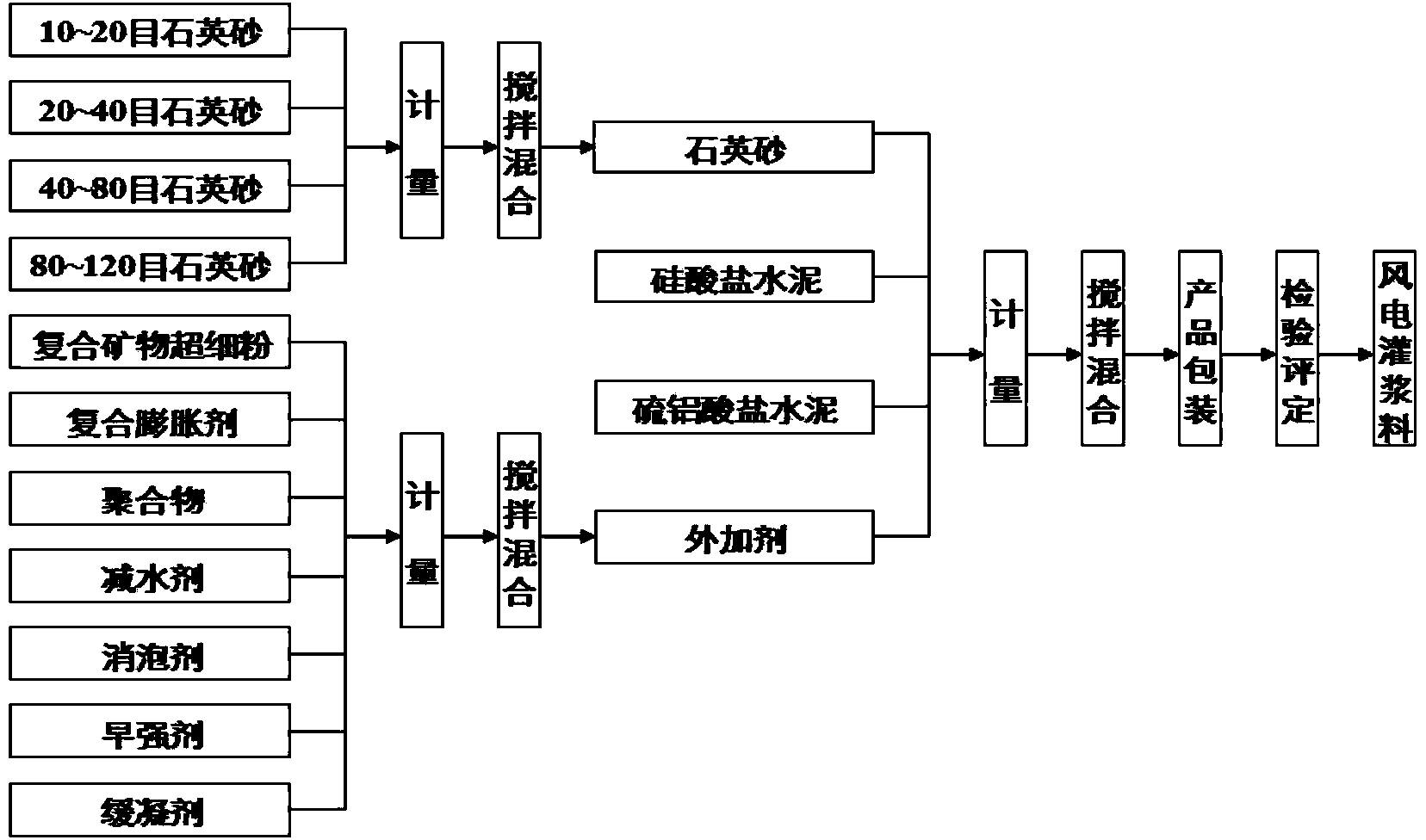

[0147] An ultra-high-performance offshore wind power jacket grouting material 1 is prepared. The composition and mass percentage of the grouting dry material are: Portland cement 25.0%, sulphoaluminate cement 5.0%, admixture 15.0%, and quartz sand 55.0%. The fineness modulus of the quartz sand is 3.4, and the composition is: 18.0% of 10-20 mesh quartz sand, 27.0% of 20-40 mesh quartz sand, 32.0% of 40-80 mesh quartz sand, and 23.0% of 80-120 mesh quartz sand. The admixture is composed of: 84.52% composite mineral ultra-fine powder (including 50.0% ultra-fine fly ash, 30.0% silicon powder, 20.0% ultra-fine slag powder), 2.00% water reducing agent, 1.50% polymer, 8.50% composite expansion agent %, defoamer 1.80%, early strength agent 1.50%, retarder 0.18%.

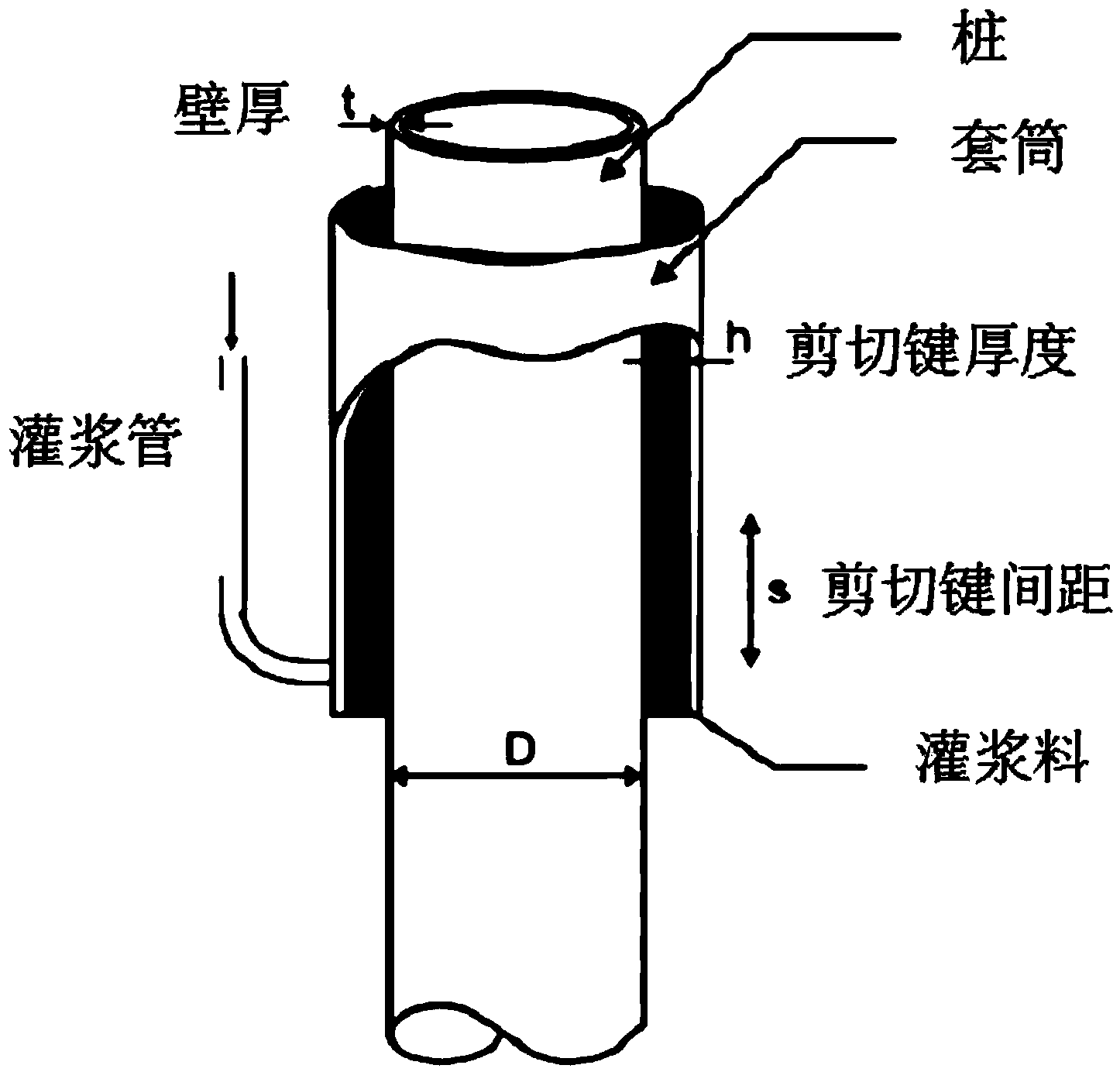

[0148] Such as Figure 1-2 As shown, the grouting dry material is pre-mixed and packaged, and the mixing water is directly added to the construction site and ful...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com