Degradable type shield tail sealing grease of shield excavation machine

A shield tail sealing and roadheader technology, which is applied in the petroleum industry, lubricating compositions, etc., can solve the problems of high cost, soil and groundwater pollution, and environmental pollution, and achieve the effect of wide temperature range and good pumping effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

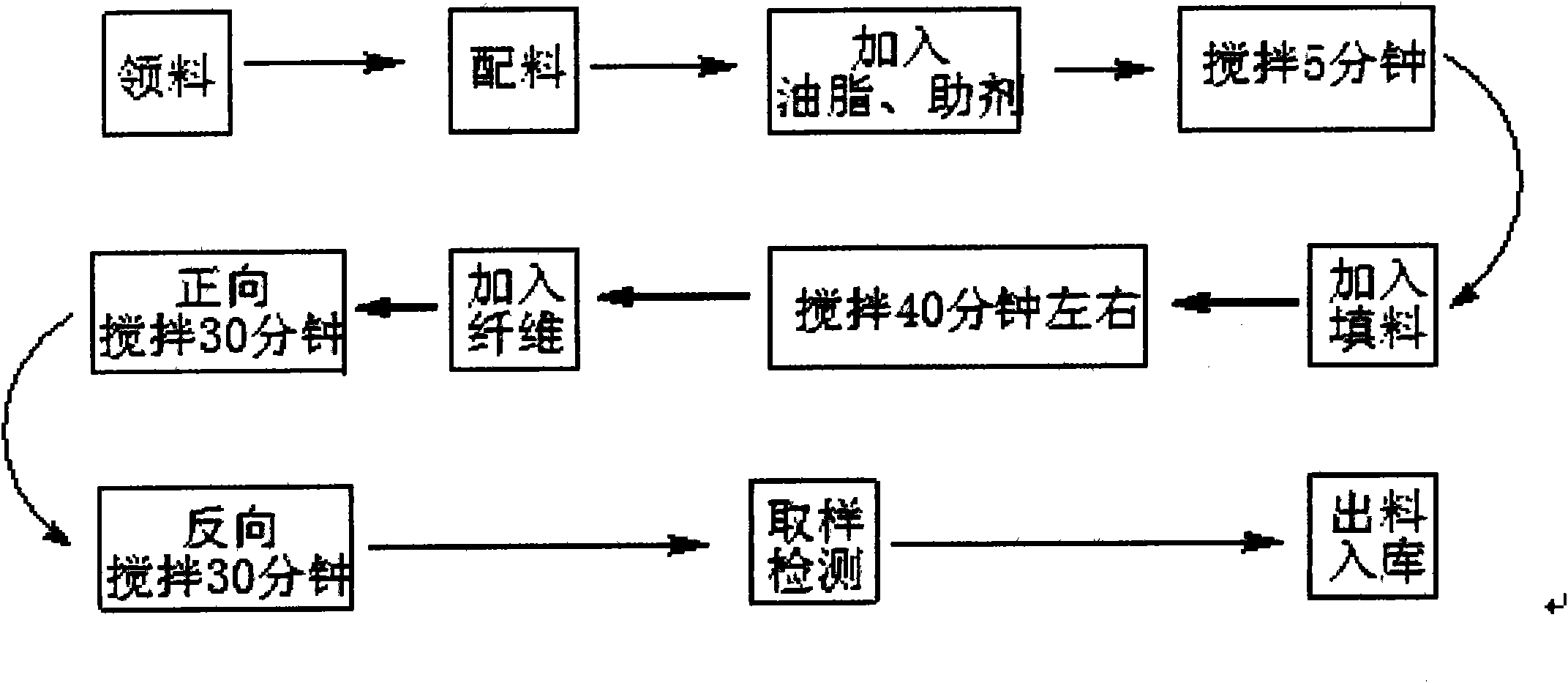

Method used

Image

Examples

Embodiment 1

[0027] First, mix 185kg of base oil, 120kg of thickener, 40kg of lubricant, 58kg of viscosity index modifier, 10kg of antirust agent, 6kg of antifungal agent, and 12kg of antioxidant at room temperature, and then add 650kg of filler Put it into a stirring tank and stir well, and finally add 25kg of plant fiber (animal fiber or synthetic fiber) and mix for 90 minutes to prepare it.

Embodiment 2

[0029] First, 50kg of polyalphaolefin (PAO500), 80kg of rapeseed oil, 55kg of castor oil, 25kg of tallow, 15kg of oleic acid, and 105kg of PB450 thickener were mixed and thinned, and then 10kg of antirust agent and 6kg of antifungal agent were added. Antioxidant 12kg, terpene resin 12kg, rosin resin 16kg, feed while stirring, then add 650kg of light calcium carbonate for stirring and mixing, finally add 25kg of plant fiber (sticky long fiber) and stir and mix for 90 minutes to obtain .

Embodiment 3

[0031] First, mix 80kg of polyalphaolefin (PAO150), 40kg of rapeseed oil, 65kg of castor oil, 25kg of beef tallow, and 15kg of 3# lithium-based grease, add 100kg of epoxy soybean oil and stir to dilute, then add 8kg of antirust agent and antifungal agent 4kg, antioxidant 13kg, terpene resin 12kg, rosin resin 10kg, T603 viscosity index modifier 6kg while stirring. Then add 320kg of light calcium carbonate and 330kg of bentonite for stirring and mixing, and finally add 25kg of plant fiber (bamboo fiber) and stir and mix for 90 minutes to obtain the mixture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ignite | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com