Nuclear reactor pressure vessel pipeline inner wall debubbling device and method

A technology of pressure vessels and nuclear reactors, applied in reactors, cooling devices, nuclear engineering, etc., can solve problems such as failure to work, and achieve an obvious effect of pumping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

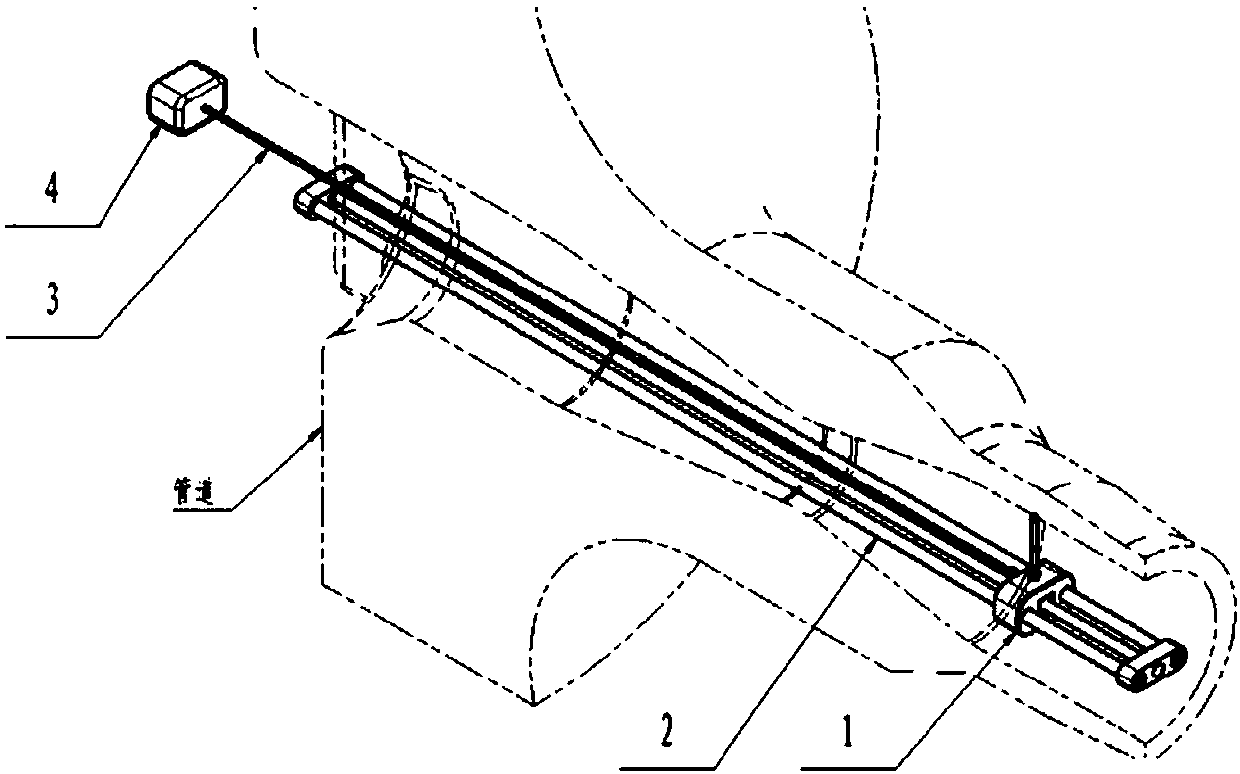

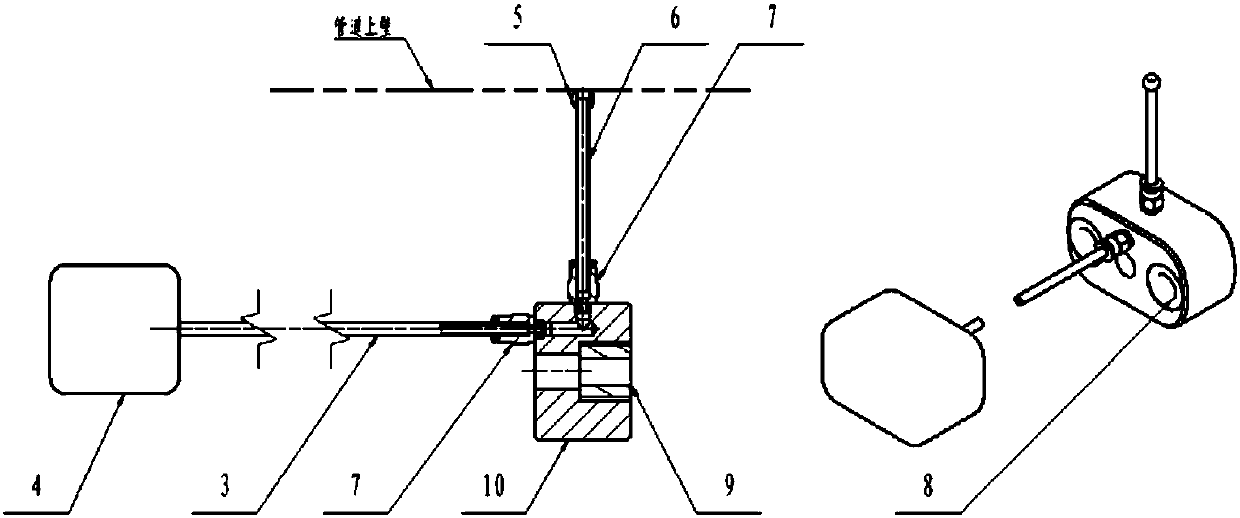

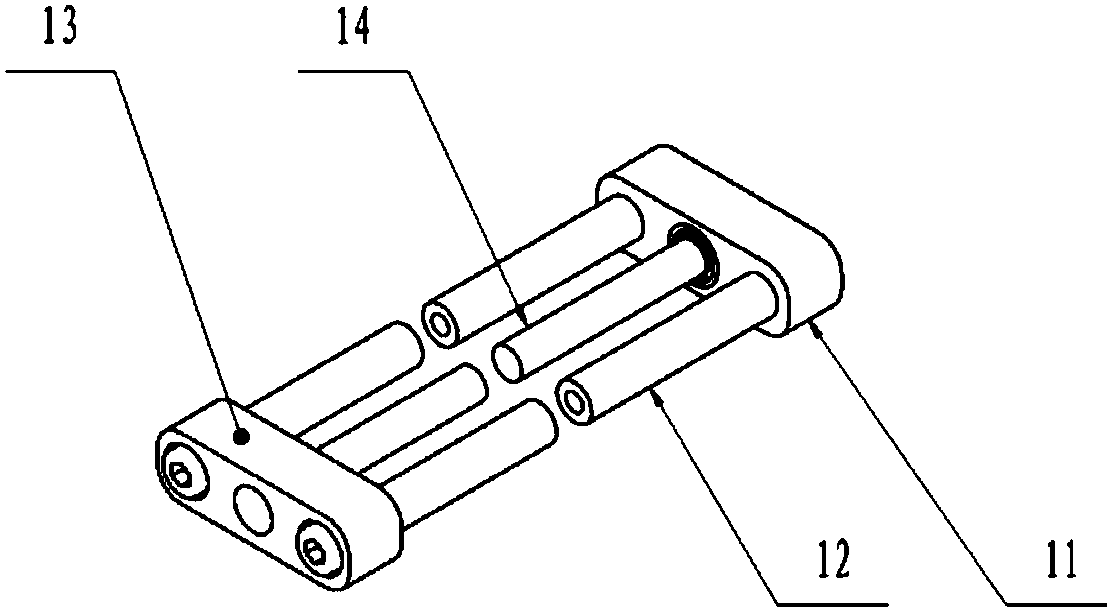

[0030] A device for removing bubbles on the inner wall of a nuclear reactor pressure vessel pipeline includes: a slider assembly 1, a linear drive assembly 2, a main air pipe 3, an air extraction device 4, a floating ball 5, a hose 6, an air pipe joint 7, a linear bearing 8, a nut 9, Slide block 10, front support base 11, guide shaft 12, rear support base 13 and leading screw 14 etc.

[0031] Among them, the function of the linear drive assembly 2 is to drive the slider assembly 1 to move linearly. When working, the front and rear ends of the linear drive assembly 2 need to be fixed in the pipeline. Bring and so on. The linear drive assembly 2 includes: a front support base 11, two guide shafts 12, a rear support base 13 and a lead screw 14, wherein one end of each guide shaft 12 is fixed on the front support base 11, and the other e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com