Rotary inflating nozzle

An inflatable nozzle and rotary technology, which is applied in the direction of variable volume pump components, liquid variable volume machinery, machines/engines, etc. The effect of reducing overall structural length and material usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings, wherein the same components use the same reference numerals.

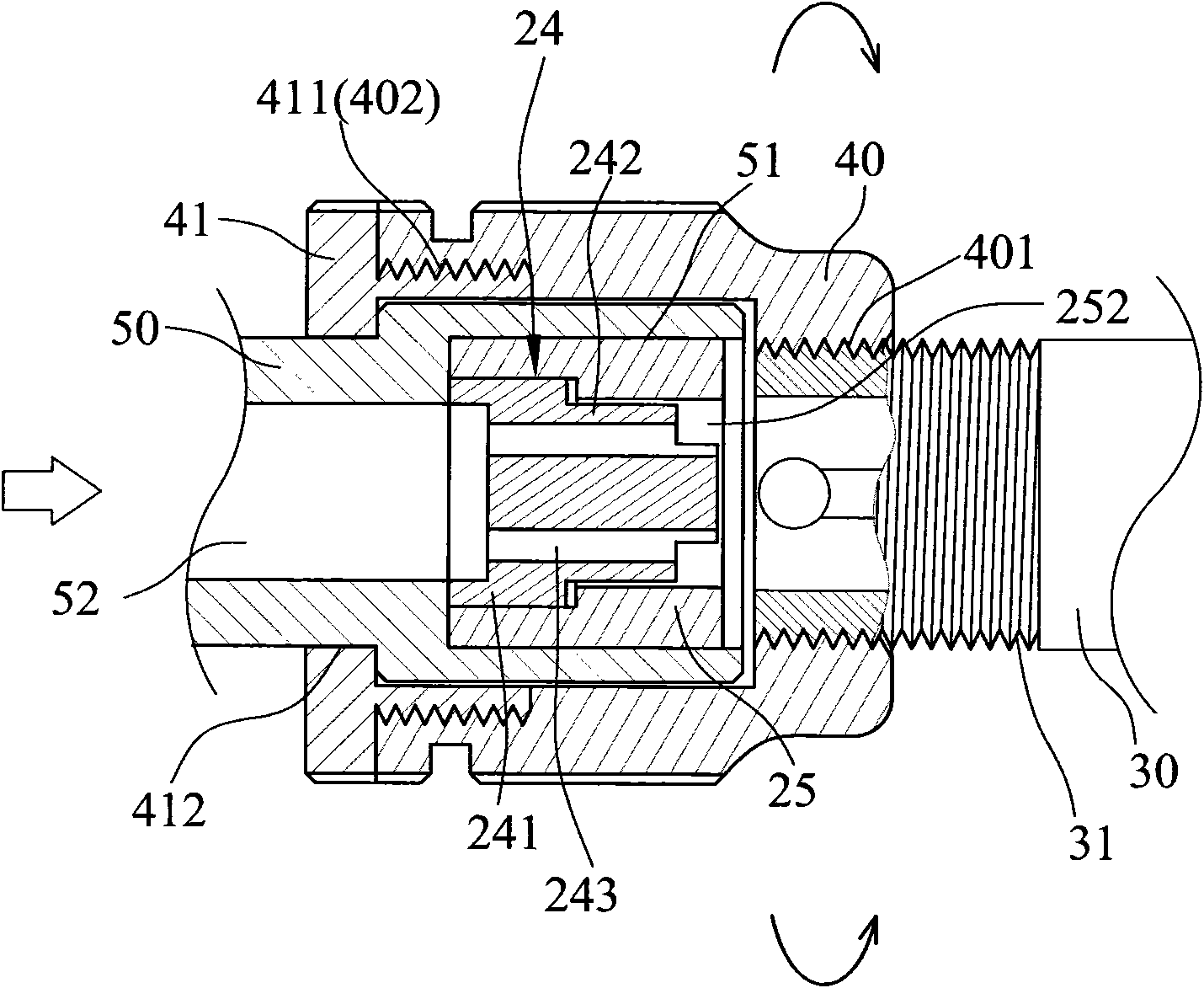

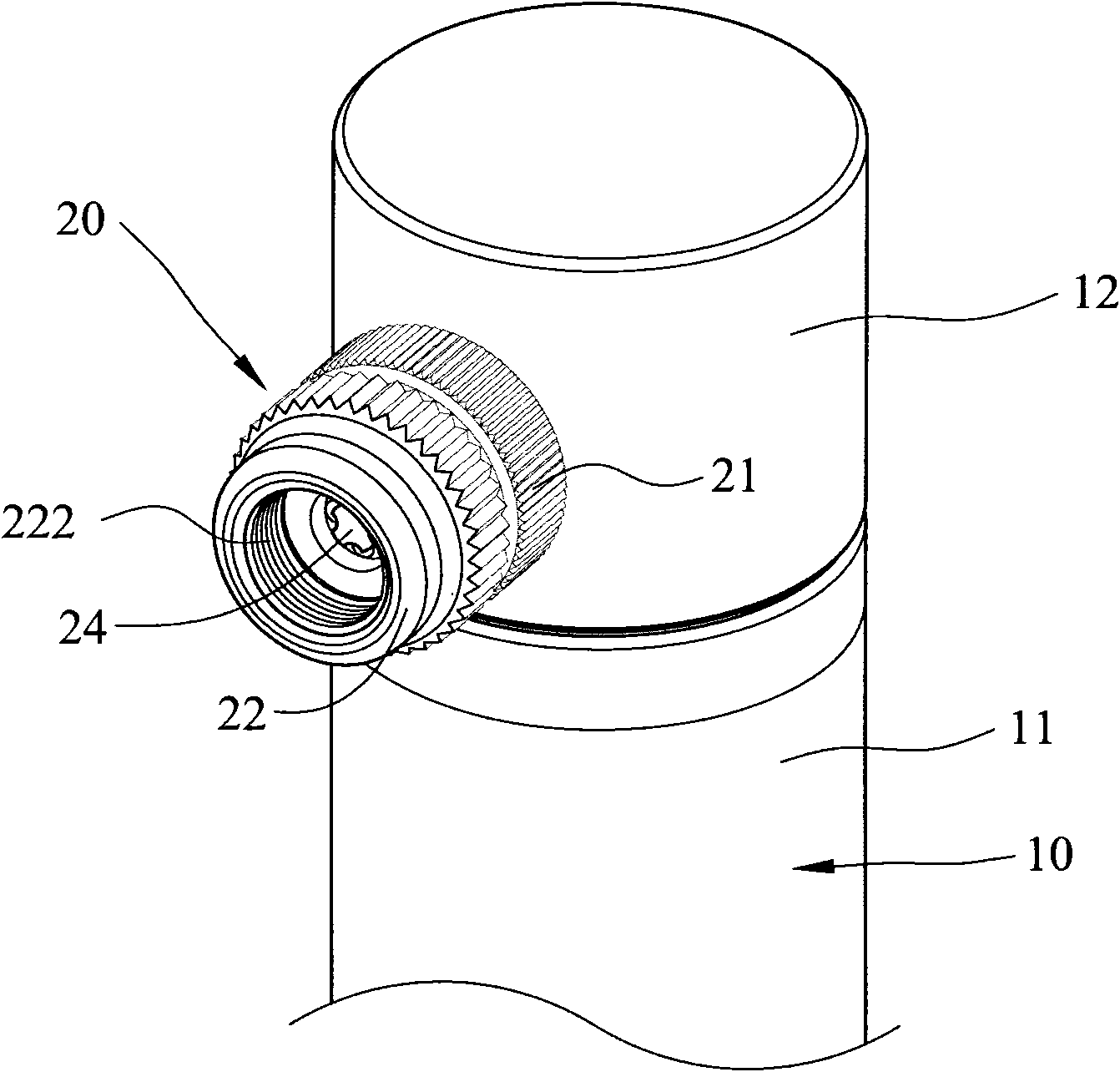

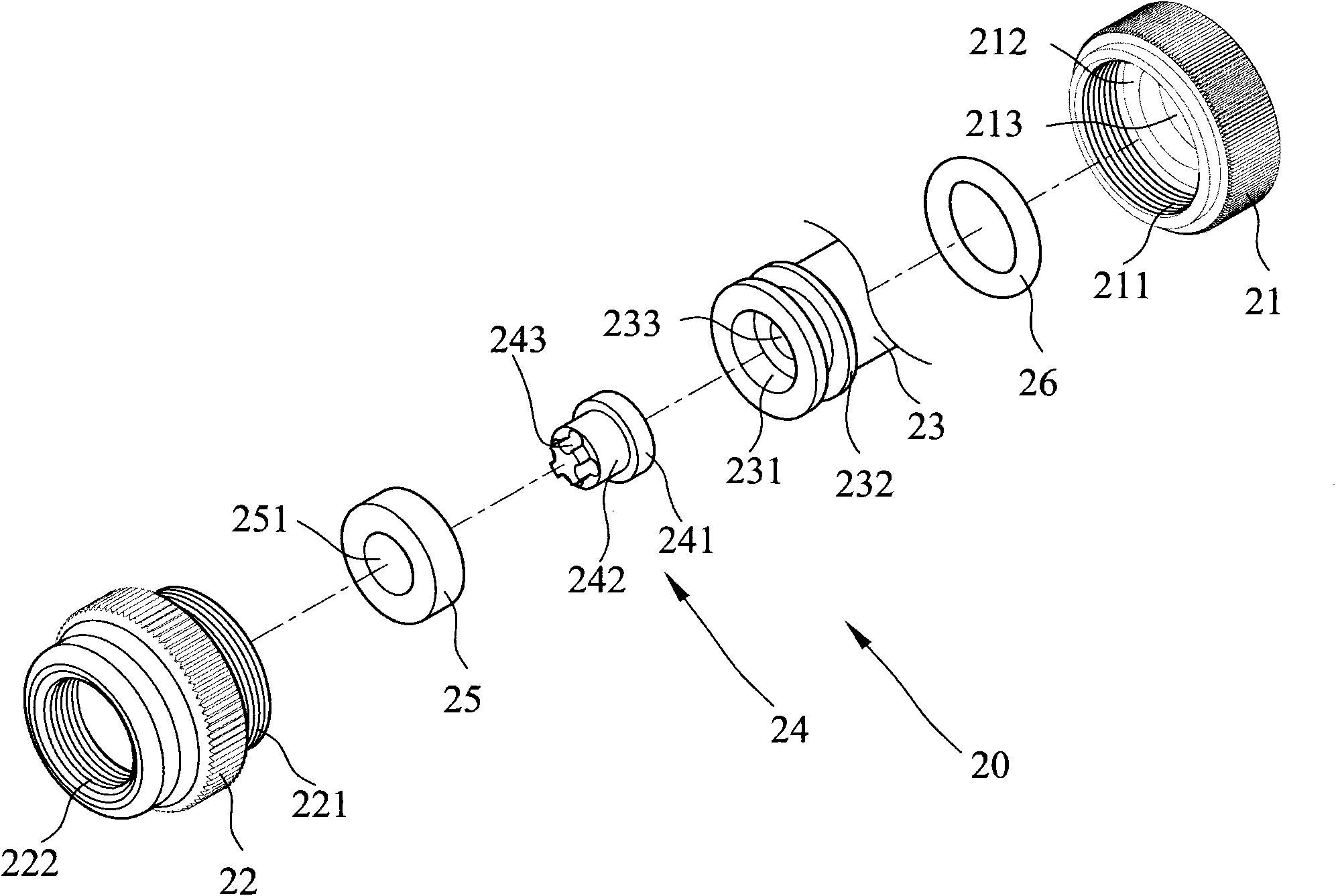

[0047] see figure 2 , image 3 and Figure 4 The schematic diagram of structural assembly and disassembly of the preferred embodiment of the present invention is shown, and the structural design of the rotary air filling nozzle 20 of the present invention can improve the length occupied by the chamber at the front end of the air nozzle plug group seat in the known structure and the volume, so the present invention cancels such as figure 1The design of the chamber 51 in the prior art shown is to keep the positioning effect of the valve plug 25 and the core tube 24, and to avoid the rotation of the valve plug 25 due to the housing 22 after the design of the chamber 51 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com