Butterfly valve

A technology of butterfly valve and valve plate, which is applied in the direction of lifting valve, valve details, valve device, etc., which can solve the problems of high mold cost, falling off, liquid leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

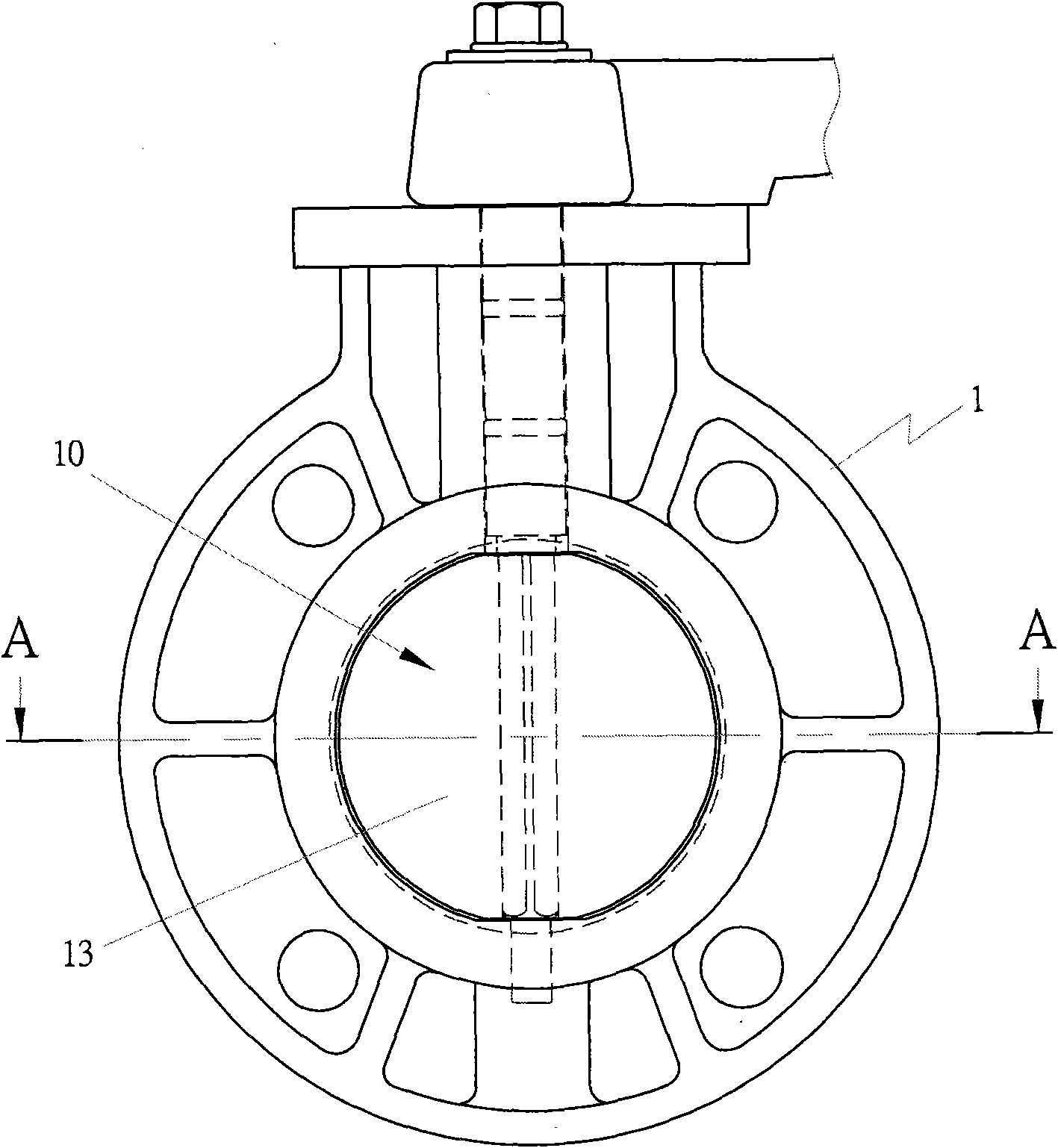

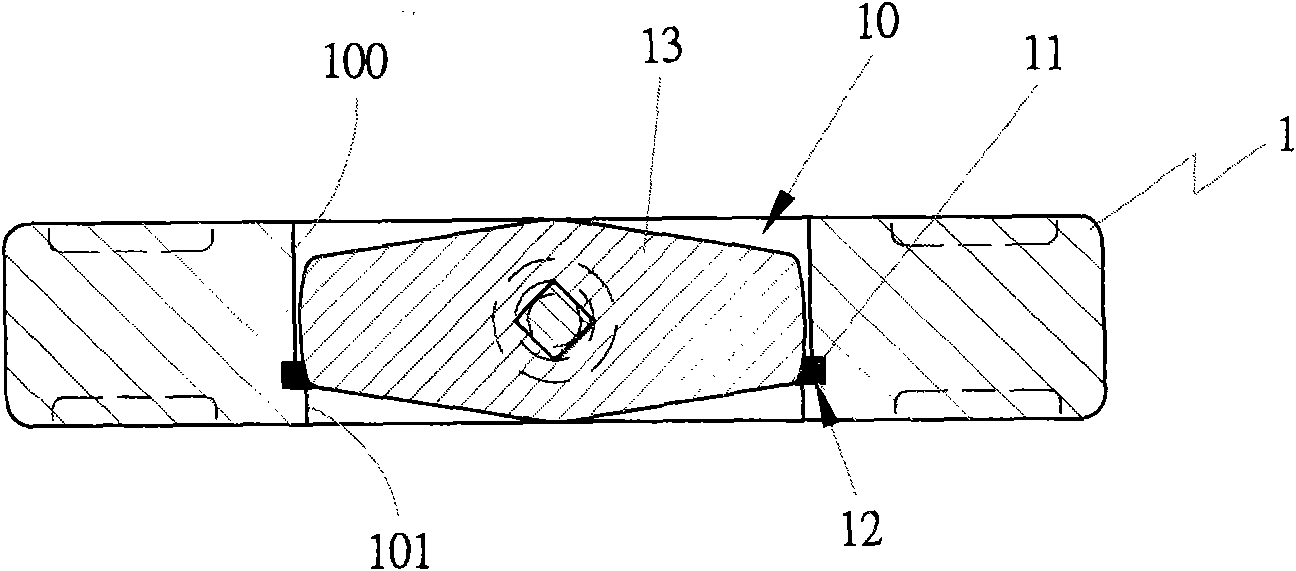

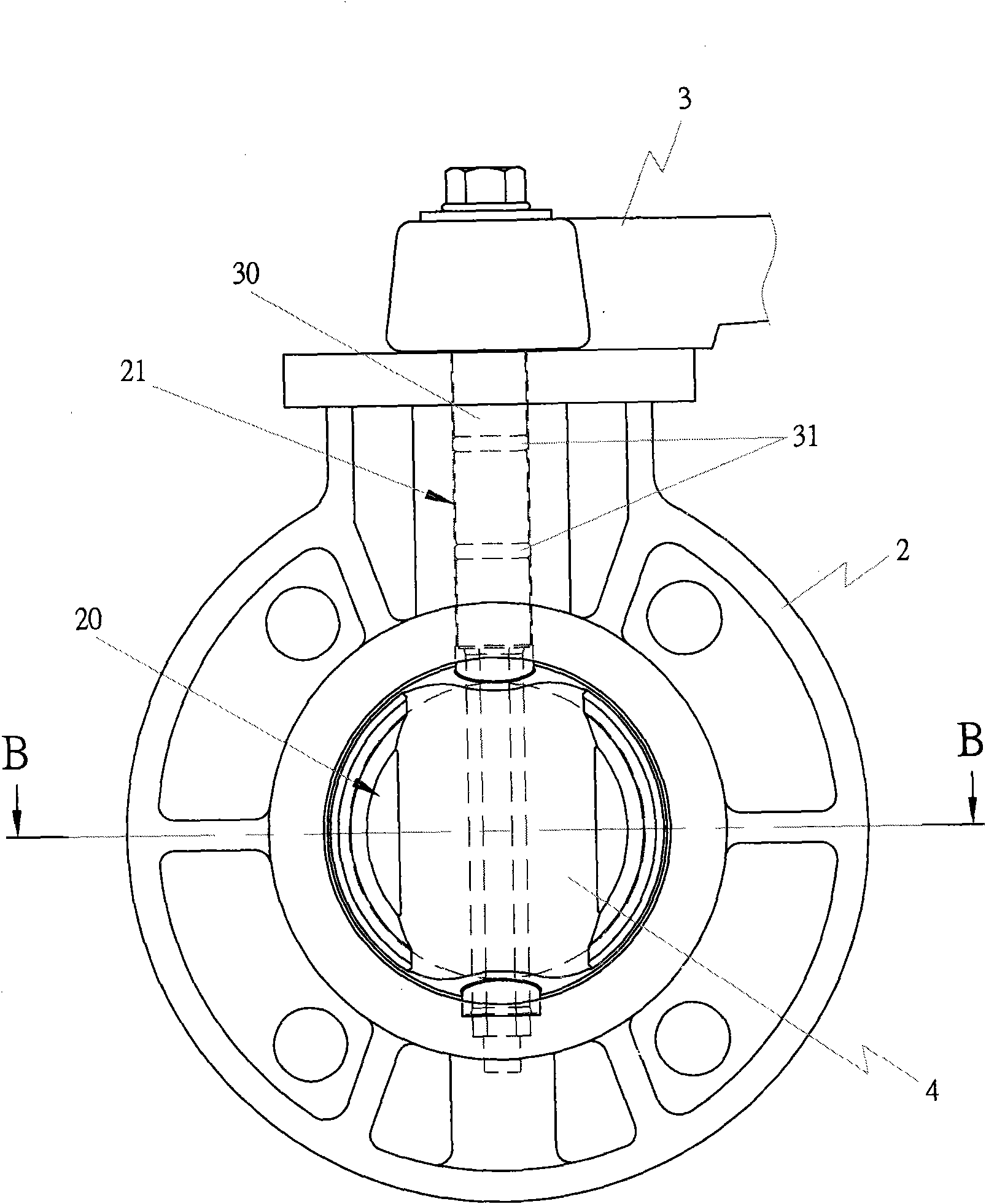

[0027] The structure and composition of the butterfly valve of the present invention and the effects it can produce are described below in detail with preferred embodiments in conjunction with the accompanying drawings:

[0028] Such as Figure 3-5 As shown, the butterfly valve of the present invention includes: a body 2 and a valve plate 4 .

[0029] The body 2 is integrally formed and provided with a valve 20. The inner wall 200 of the valve 20 is a through-shaped hole. The inner diameter of the hole is consistent from front to back, which is convenient for the mold making of the body 2. When the body 2 is injection-molded with plastic raw materials, it will be faster. And stable. The body 2 is provided with a handle 3, the handle 3 is provided with a shaft 30, and the shaft 30 is accommodated in the hole 21, so that the shaft 30 enters the accommodation hole 21 from the top of the body, and passes through the shaft hole of the valve plate 4, so that the handle 3 can contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com