End cover assembly of battery

A technology for end caps and batteries, which is applied to battery pack components, small-sized batteries/battery packs, battery boxes/coats, etc., and can solve problems such as inability to maintain airtightness and electrolyte leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Hereinafter, reference is made to the drawings in order to more fully describe embodiments of the present invention. However, the invention may be practiced in many different forms and should not be construed as limited to the embodiments set forth herein. In addition, the sizes and relative sizes of layers and regions may be exaggerated in the drawings for the sake of clarity and not drawn to scale.

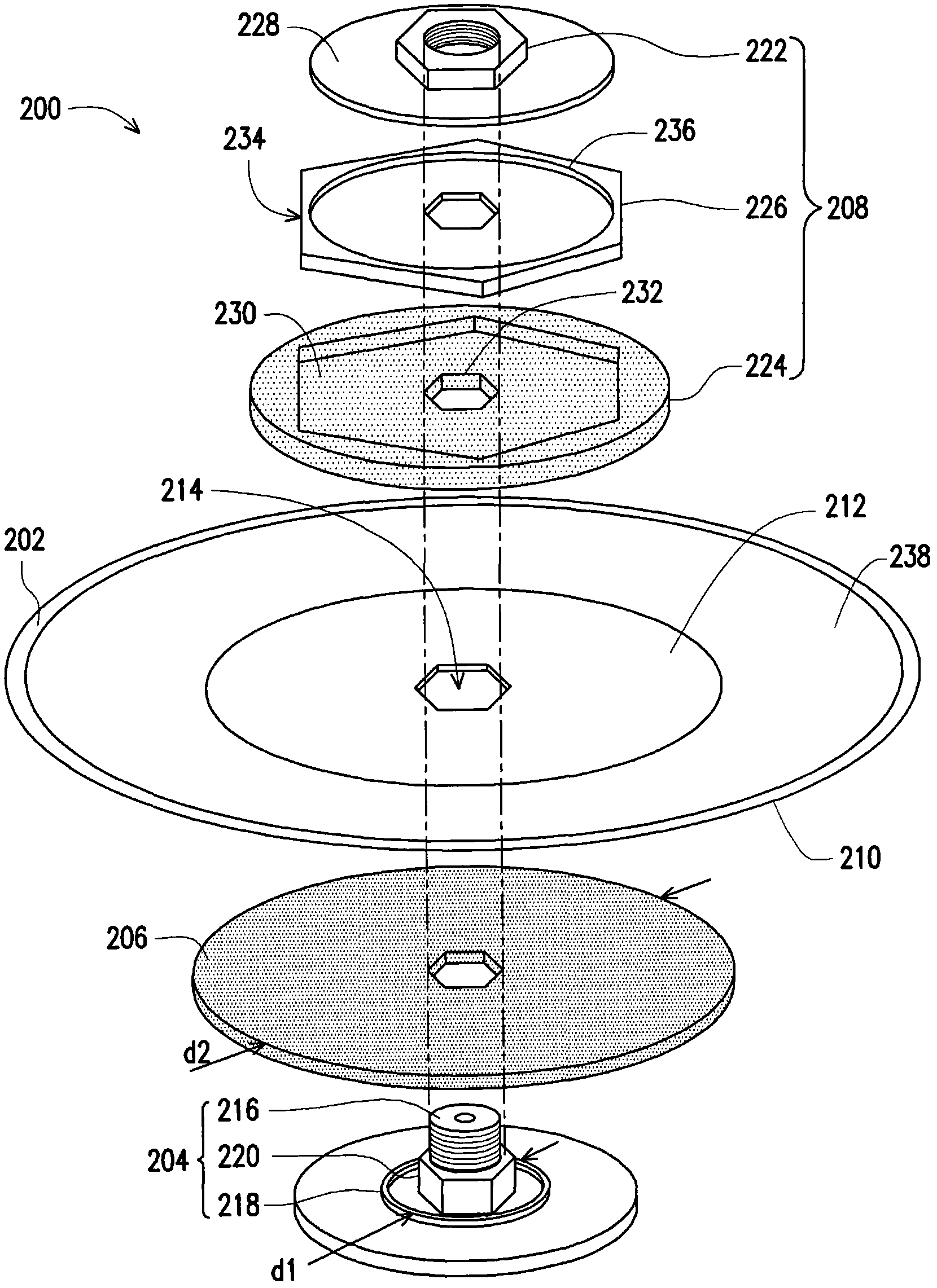

[0048] figure 2 It is a three-dimensional exploded view of a battery end cover assembly of an embodiment.

[0049] Please refer to figure 2 , the battery end cover assembly 200 includes a battery end cover 202 , a terminal base 204 , an airtight insulating gasket 206 and a fixing component 208 . The battery end cover 202 has a first surface 210 and a second surface 212 opposite to each other and a first opening 214 passing through the first and second surfaces 210 , 212 . The terminal base 204 is located on the first surface 210 of the battery end cover 202. The ter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com