Hyperbranched polymer, hyperbranched type water reducing agent of polycarboxylic acid series and preparation method and application thereof

A technology of hyperbranched polymer and hyperbranched polymer, which is applied in the field of hyperbranched polymer and hyperbranched carboxylic acid-based water reducing agent, can solve the problems of low water reducing rate and poor cement adaptability, etc. The effect of strong frost resistance, superior performance and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

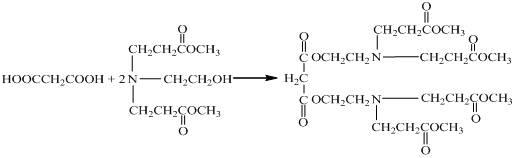

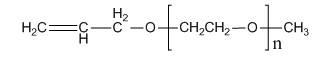

[0051] Using a magnetic stirrer and water bath heating and a three-necked flask with a nitrogen inlet and a condenser, add 17.2g methyl acrylate, 6.1g ethanolamine and 10ml methanol, stir the mixture at room temperature for 30min and then heat up to 40°C for 10h , and then the methanol was removed by rotary evaporation to obtain a colorless transparent oil, N-hydroxyethyl-3-amino-N,N-dipropionic acid methyl ester monomer. Add 1.041g malonic acid and 4.665g N-hydroxyethyl-3-amino-N,N-dipropionic acid methyl ester, 10mL toluene, 15mL N-N dimethyl Acetamide (DMAc) and 0.028g p-toluenesulfonic acid, add 20mL toluene to the water trap. The mixture was reacted in a boiling state for 7 h, and then the toluene and DMAc were distilled off under reduced pressure to obtain a light yellow oily product, which was the first-generation ester-terminated hyperbranched poly(amine-ester). Continue to add 9.33g of N-hydroxyethyl-3-amino-N,N-dipropionate methyl ester monomer and 0.04g of p-phenyl...

Embodiment 2

[0053] Using a magnetic stirrer and water bath heating and a three-necked flask with a nitrogen inlet and a condenser tube, add 17.2g methyl acrylate, 6.1g ethanolamine and 10ml methanol, and the mixture is stirred at room temperature and nitrogen for 20-30min and then heated to 40- Keep at 50°C for 8-10h, then remove the methanol by rotary evaporation to obtain a colorless transparent oil, N-hydroxyethyl-3-amino-N,N-dipropionic acid methyl ester monomer. Add 1.041g malonic acid and 4.665g N-hydroxyethyl-3-amino-N,N-dipropionic acid methyl ester, 10mL toluene, 15mL N-N dimethyl Acetamide (DMAc) and 0.028g p-toluenesulfonic acid, add 20mL toluene to the water trap. The mixture was reacted in a boiling state for 5-7h, and then the toluene and DMAc were distilled off under reduced pressure to obtain a light yellow oily product, which was the first-generation ester-terminated hyperbranched poly(amine-ester). Continue to add 9.33g of N-hydroxyethyl-3-amino-N,N-methyl dipropionate ...

Embodiment 3

[0055] Using a magnetic stirrer and water bath heating and a three-necked flask with a nitrogen inlet and a condenser, add 17.2g methyl acrylate, 6.1g ethanolamine and 10ml methanol, stir the mixture at room temperature for 30min and then heat up to 40°C for 10h , and then the methanol was removed by rotary evaporation to obtain a colorless transparent oil, N-hydroxyethyl-3-amino-N,N-dipropionic acid methyl ester monomer. Add 1.041g malonic acid and 4.665g N-hydroxyethyl-3-amino-N,N-dipropionic acid methyl ester, 10mL toluene, 15mL N-N dimethyl Acetamide (DMAc) and 0.028g p-toluenesulfonic acid, add 20mL toluene to the water trap. The mixture was reacted in a boiling state for 7 h, and then the toluene and DMAc were distilled off under reduced pressure to obtain a light yellow oily product, which was the first-generation ester-terminated hyperbranched poly(amine-ester). Continue to add 9.33g of N-hydroxyethyl-3-amino-N,N-dipropionate methyl ester monomer and 0.04g of p-phenyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com