Slow-release cationic anti-mud polycarboxylic-type high performance water reducer and preparation method thereof

A cationic, clay-polycarboxylic acid technology, applied in the field of concrete admixture, can solve the problems of no mud-resistant functional group, difficult mud-resistant effect, cumbersome process, etc., achieve good slow-release effect, improve work performance, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

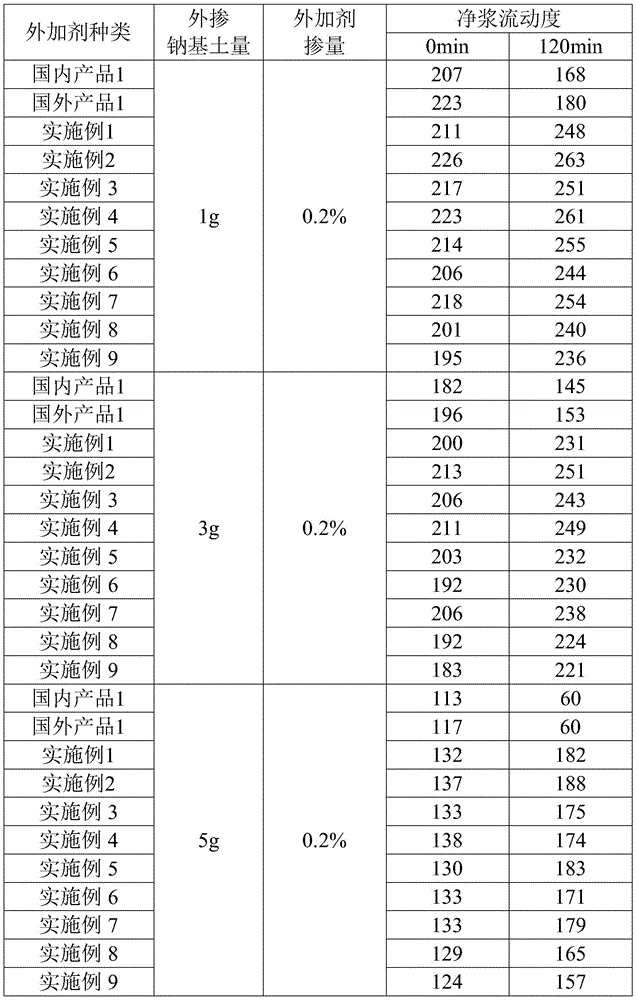

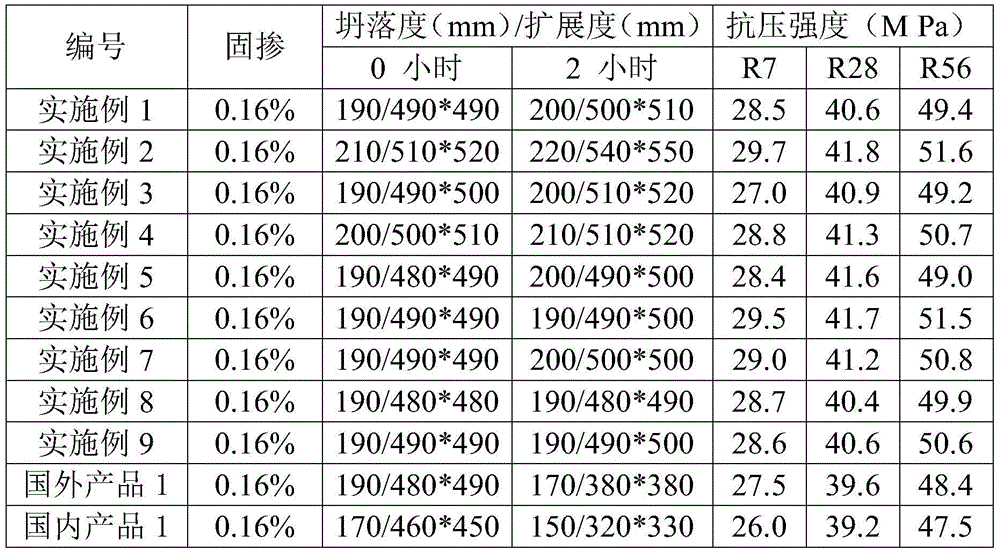

Examples

Embodiment 1

[0030] Prepare the slow-release cationic anti-sludge polycarboxylate high-performance water reducer according to the following raw material quantity and process, specifically:

[0031] The first step of material preparation: 0.49g of hanging white block and 280g of water are fully stirred to prepare solution A; 9g of acrylic acid, 25.38g of hydroxyethyl acrylate, 7.5g of polyethylene glycol diester maleate, dimethyl diallyl chloride 5.05g of ammonium chloride, 0.46g of mercaptopropionic acid and 277g of water were fully stirred to prepare solution B.

[0032] The second step of polymerization: Add 150g of isobutylene alcohol polyoxyethylene ether and 250g of water into a glass reactor with a thermometer and an electric stirrer, stir until completely dissolved, add 0.89g of 30% hydrogen peroxide, stir evenly, and start Control the temperature between 20 and 30°C and start to add materials A and B dropwise; add material A dropwise for 2.5 hours, add material B dropwise for 2 hou...

Embodiment 2

[0034] Prepare the slow-release cationic anti-sludge polycarboxylate high-performance water reducer according to the following raw material quantity and process, specifically:

[0035] The first step of material preparation: 0.75g of L-ascorbic acid and 156g of water are fully stirred to prepare solution A; 12.25g of maleic anhydride, 29g of hydroxyethyl acrylate, 12.5g of polyethylene glycol diester, dimethyldiallyl 10.10 g of ammonium chloride, 0.66 g of mercaptopropionic acid and 156 g of water were fully stirred to prepare solution B.

[0036] The second step of polymerization: Add 75g of isobutenol polyoxyethylene ether, 75g of isopentenol polyoxyethylene ether and 200g of water into a glass reactor with a thermometer and an electric stirrer, stir until they are all dissolved, and add 30% super Hydrogen oxide 1.07g, stir evenly, control the initial temperature between 20-30°C and start adding material A and B dropwise; add material A dropwise for 2h, add material B dropwi...

Embodiment 3

[0038] Prepare the slow-release cationic anti-sludge polycarboxylate high-performance water reducer according to the following raw material quantity and process, specifically:

[0039] The first step of material preparation: 1.06g of hanging white block and 105g of water are fully stirred to prepare solution A; 14.5g of fumaric acid, 18.13g of hydroxyethyl acrylate, 20.31g of hydroxypropyl acrylate, 17.5g of polyethylene glycol diester maleate g, 15.16 g of dimethyl diallyl ammonium chloride, 0.99 g of mercaptopropionic acid and 108 g of water were fully stirred to prepare solution B.

[0040] The second step of polymerization: Add 150g of isobutylene alcohol polyoxyethylene ether and 150g of water into a glass reactor with a thermometer and an electric stirrer, stir until they are completely dissolved, add 1.42g of sodium persulfate, stir evenly, and control the initial temperature at Start to add material A and B dropwise between 20 and 30°C; add material A dropwise for 2 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com