Concrete inner curing agent and preparing method thereof

A concrete internal curing agent technology, which is applied in the field of concrete internal curing agent and its preparation, can solve the problems of large slump changes over time, poor cement compatibility, and insufficient economy, so as to reduce post-maintenance costs and high water-reducing rate , Good for environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

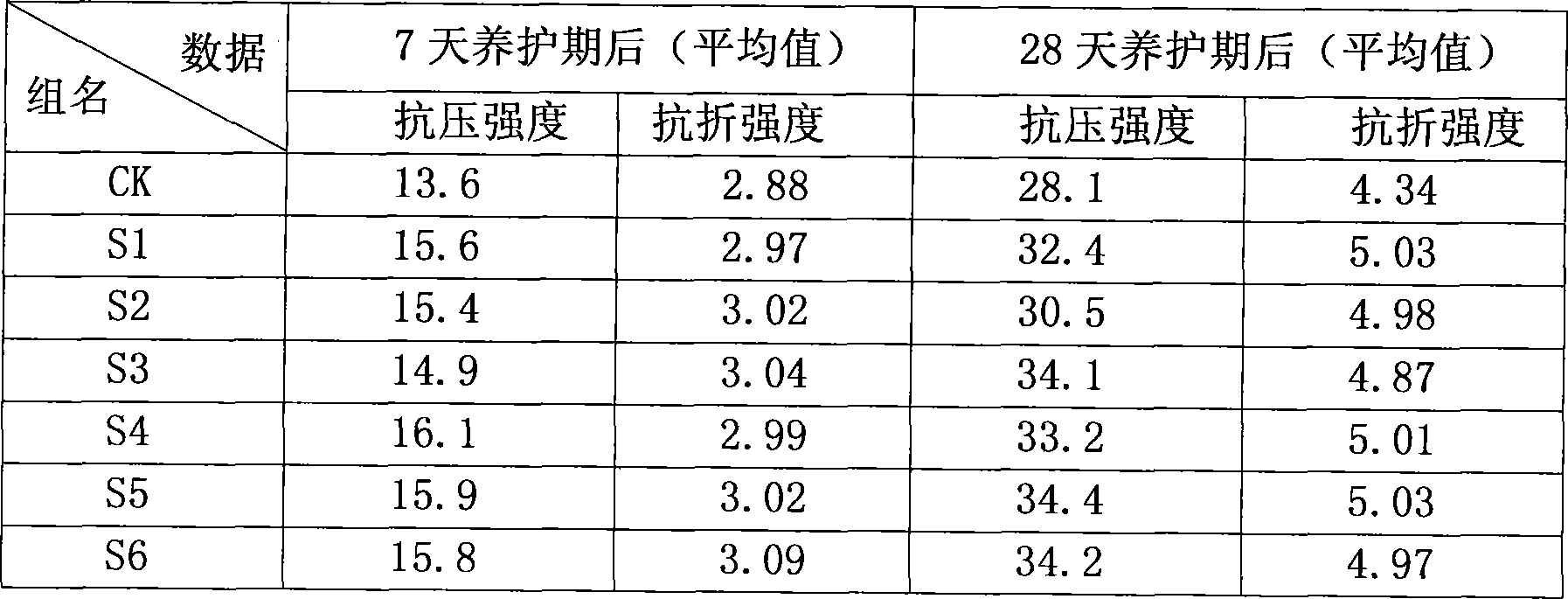

Examples

Embodiment 1

[0047] formula:

[0048] Deionized water 55%, bentonite 3%, sodium hydroxide 3%, acrylic acid 15%, acrylamide 15%, ammonium persulfate 0.001%, N'N-methylenebisacrylamide 0.0005%, additive 8.9985% (of which Kaolin 50%, ethylene oxide 10%, urea 10%, talc 30%)

[0049] Preparation:

[0050] First, mix deionized water, sodium hydroxide, acrylic acid, acrylamide, etc., and control the temperature of the mixture at 30 degrees; then add N'N-methylenebisacrylamide, ammonium persulfate, bentonite, and ethylene oxide in sequence , urea, stir evenly, use aqueous solution in-situ polymerization composite method, 50 ℃ -110 ℃ hot air circulation heating for 3 hours, continue to dry and pulverize, mix evenly with kaolin and talcum powder, and then get powder concrete internal curing agent.

Embodiment 2

[0052] formula:

[0053] Deionized water 2%, montmorillonite 65%, sodium hydroxide 2.5%, acrylic acid 15%, acrylamide 15%, potassium persulfate 0.001%, N'N-methylenebisacrylamide 0.00001%, additive 0.49899% (including 50% ethylene oxide, 50% urea)

[0054] Preparation:

[0055] First, mix deionized water, sodium hydroxide, acrylic acid, acrylamide, etc., and control the temperature of the mixture at 30 degrees; then add N'N-methylenebisacrylamide, potassium persulfate, montmorillonite, epoxy Mix ethane and urea evenly, and heat with hot air circulation at 50°C-110°C for 2 hours to obtain a solution-type concrete internal curing agent.

Embodiment 3

[0057] formula:

[0058] Deionized water 2%, montmorillonite 10%, bentonite 25%, sodium hydroxide 2%, acrylic acid 55%, potassium persulfate 0.0008%, N'N-methylenebisacrylamide 0.0003%, additive 5.9989% ( Among them, kaolin 28%, ethylene oxide 12%, urea 30%, talcum powder 30%)

[0059] Preparation:

[0060]First, mix deionized water, sodium hydroxide, acrylic acid, etc., and control the temperature of the mixture at 30 degrees; then add N'N-methylenebisacrylamide, potassium persulfate, montmorillonite, bentonite, and ethylene oxide in sequence Alkanes, urea, stir evenly, use aqueous solution in-situ polymerization composite method, 50 ℃ -110 ℃ hot air circulation heating for 4 hours, continue to dry and pulverize, stir and mix with kaolin and talcum powder evenly, that is, the powder type concrete internal curing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com