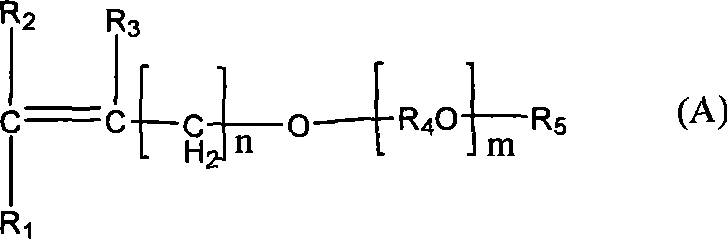

Polycarboxylic acid water reducing agent

A technology of water reducing agent and polycarboxylic acid, applied in the field of polycarboxylic acid water reducing agent, can solve problems such as poor slump retention performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

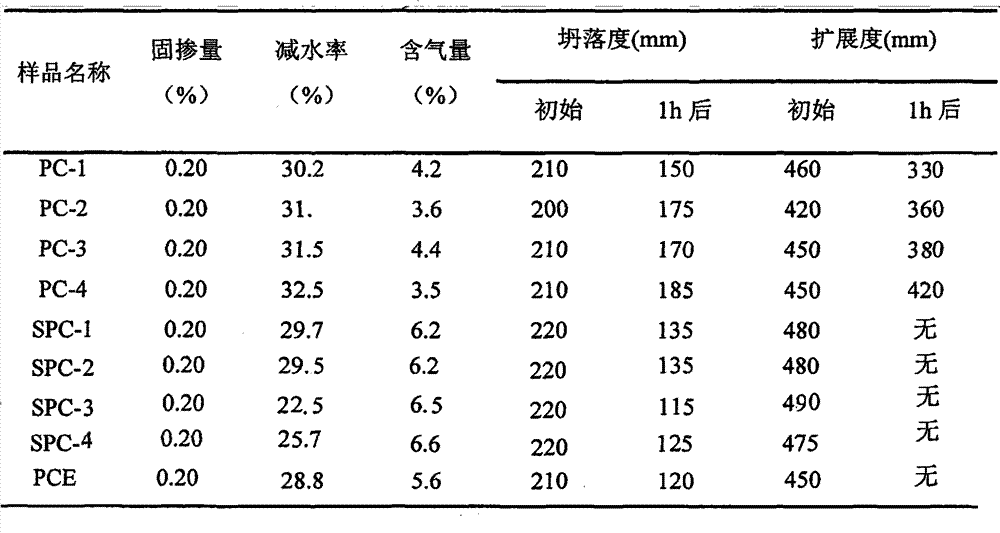

Examples

Embodiment 1

[0036] Add 25.0g of A-1, 60.0g of water, and 5.0g of 30% hydrogen peroxide into a 500ml four-necked flask equipped with a stirrer, a thermometer and a dropping device, and stir to raise the temperature to 65°C. At the same time, 21.6g vitamin C aqueous solution (obtained by dissolving 0.4g vitamin C, 1.2g 3-mercaptopropionic acid in 20.0g water) and 159.0g monomer aqueous solution (obtained by 50.0g B-1, 10.0g C-1, 21.0 gD-1 mixed with 78.0 g of water), the dropping time was controlled at 210 minutes and 180 minutes respectively, and the reaction temperature was controlled at 63-67°C. After the dropwise addition, keep the temperature at 63-67°C for 30 minutes to complete the polymerization reaction. After the heat preservation is completed, lower the temperature to below 50°C and add 44.4g of 30% NaOH aqueous solution to obtain the polycarboxylate superplasticizer PC-1 of the present invention, which has a solid content of 42.5% and a weight average molecular weight of 107,500...

Embodiment 2

[0038] Add 10.0 g of A-2, 50.0 g of water, and 5.0 g of 30% hydrogen peroxide into a 500 ml four-necked flask equipped with a stirrer, a thermometer, and a dropping device, and stir to raise the temperature to 65°C. At the same time, 22.1g vitamin C aqueous solution (obtained by dissolving 0.6g vitamin C, 1.5g 3-mercaptopropionic acid in 20.0g water) and 146.0g monomer aqueous solution (obtained by 65.0g B-1, 1.0g C-1, 30.0g D -1 dissolved in 50.0 g of water), the dropping time was controlled at 210 minutes and 180 minutes respectively, and the reaction temperature was controlled at 63-67°C. After the dropwise addition, keep the temperature at 63-67°C for 30 minutes to complete the polymerization reaction. After the heat preservation is completed, lower the temperature to below 50° C. and add 37.0 g of 30% NaOH aqueous solution to obtain the polycarboxylate superplasticizer PC-2 of the present invention, which has a solid content of 45.6% and a weight average molecular weight ...

Embodiment 3

[0040] Add 25.0 g of A-3, 50.0 g of water, and 5.0 g of 30% hydrogen peroxide into a 500 ml four-necked flask equipped with a stirrer, a thermometer, and a dropping device, and stir to raise the temperature to 65°C. At the same time, 22.1g of vitamin C aqueous solution (obtained by dissolving 0.6g of vitamin C and 1.5g of 2-mercaptopropionic acid in 20.0g of water) and 200.0g of monomer aqueous solution (from 50.0g of B-2 and 10.0g of C-2, 21.0 g D-2 was dissolved in 78.0 g of water), the dropping time was controlled at 180 minutes and 150 minutes respectively, and the reaction temperature was controlled at 63-67°C. After the dropwise addition, keep the temperature at 63-67°C for 30 minutes to complete the polymerization reaction. After the heat preservation is completed, lower the temperature to below 50°C and add 42.0 g of 30% sodium hydroxide aqueous solution to obtain the polycarboxylate water reducer PC-3 of the present invention, which has a solid content of 48.8% and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com