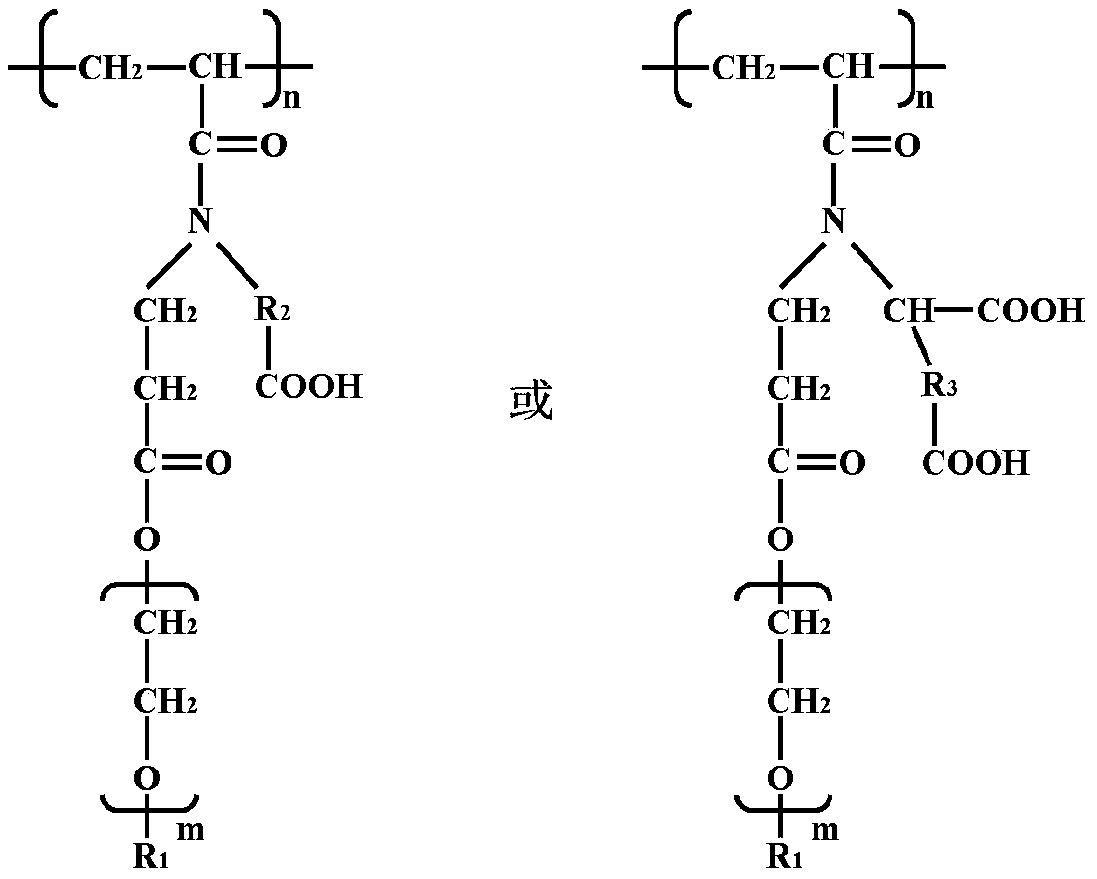

A preparation method of polycarboxylate water reducer with regular sequence structure

A technology of polycarboxylic acid and water reducing agent, applied in the field of concrete admixtures, can solve the problems of fast slump loss, poor cement adaptability, insufficient water reducing effect, etc., and achieve the effects of low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

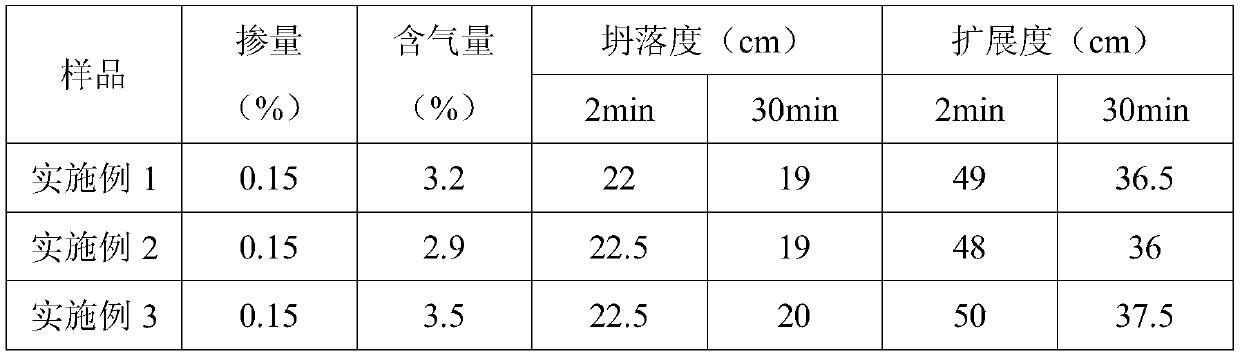

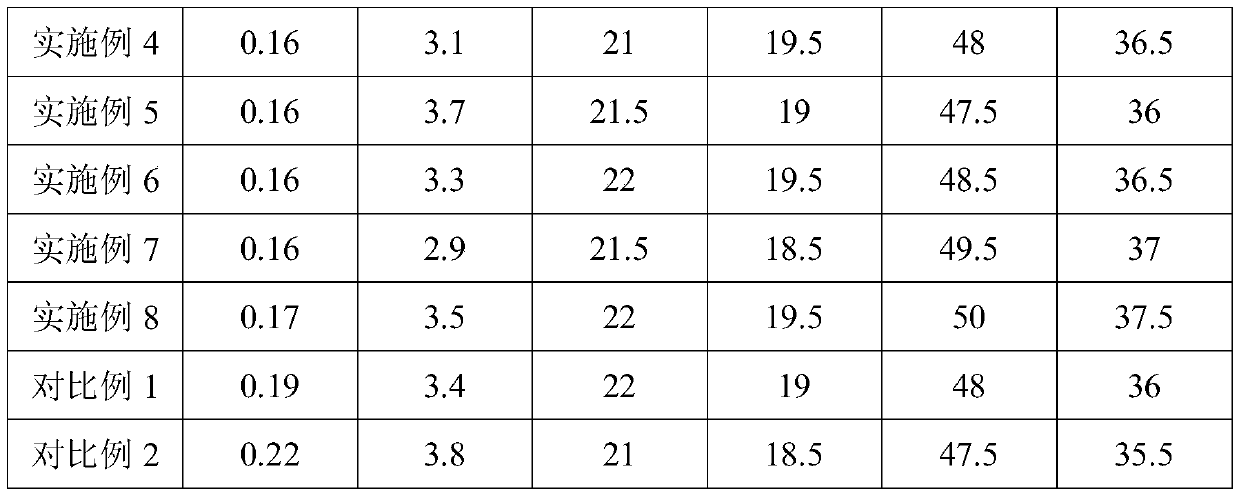

Examples

Embodiment 1

[0033]Add 100g of A-1 and 17.82g of B-1 to a flask equipped with a stirrer, carry out Michael addition reaction at 10°C for 5h, then cool down to 0°C, slowly add 18.1g of acryloyl chloride dropwise, dropwise After 30min finishes, continue to react at room temperature for 12h; Continue to drop into small molecule RAFT reagent BDMAT1.18g, initiator potassium persulfate 0.36g and water 320g in the flask, this moment polymerization concentration is 30%, in N 2 Under the atmosphere, the temperature was raised to 60°C, and after 2 hours of reaction, a polycarboxylate superplasticizer with a regular sequence structure was obtained, with a weight-average molecular weight of 25,300.

Embodiment 2

[0035] Add 187.5g of A-2 and 30.93g of B-2 to a flask equipped with a stirrer, perform Michael addition reaction at 30°C for 7 hours, then cool down to 0°C, slowly add 27.15g of acryloyl chloride dropwise, dropwise After adding 30min, continue the reaction at room temperature for 12h; continue to drop into the flask 0.92g of small molecule RAFT reagent BDMAT, 0.14g of initiator ammonium persulfate and 250g of water. At this time, the polymerization concentration is 50%. 2 Under the atmosphere, the temperature was raised to 70°C, and after 3 hours of reaction, a polycarboxylate water reducer with a regular sequence structure was obtained, with a weight average molecular weight of 37,600.

Embodiment 3

[0037] Add 165g of A-3 and 39.83g of B-3 into a flask equipped with a stirrer, perform Michael addition reaction at 50°C for 12h, then cool down to 0°C, slowly add 15.08g of acryloyl chloride dropwise, dropwise After 30min, continue to react at room temperature for 12h; continue to drop into the flask 1.01g of small molecule RAFT reagent CETPA, 0.23g of initiator V-50 and 330g of water. At this time, the polymerization concentration is 40%. 2 Under the atmosphere, the temperature was raised to 80°C, and after 5 hours of reaction, a polycarboxylate water reducer with a regular sequence structure was obtained, with a weight average molecular weight of 52,300.

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight-average molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com