Preparation method of phenolic ether polycarboxylate concrete slushing agent

A concrete water-reducing agent and polycarboxylic acid-based technology, which is applied in the field of concrete water-reducing agent preparation, can solve the problems of toxicity of the starting agent, easy gasification, overpressure of the reactor, etc., and achieves wide product adaptability and cement adaptability. Good performance and stable product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

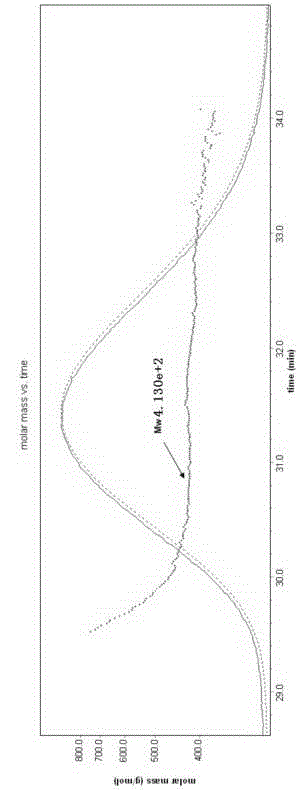

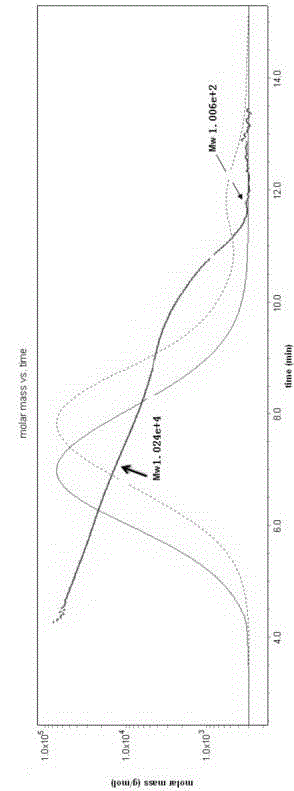

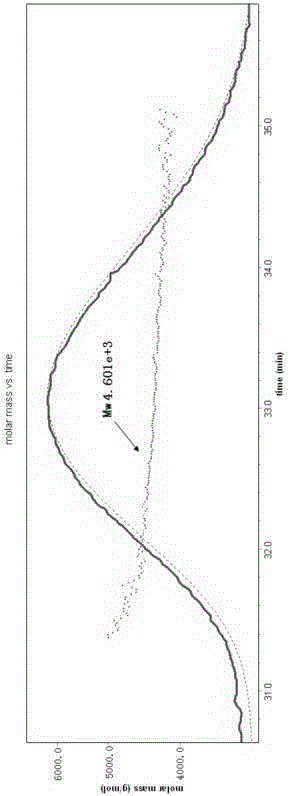

Image

Examples

Embodiment 1

[0039] Add 60.15 grams of 4-vinylphenol into the reactor, add 0.11 grams of potassium hydroxide, replace with nitrogen three times, raise the temperature to 110±5°C, turn on the vacuum pump to remove the moisture in the raw materials under the pressure of -0.099MPa, The dehydration time is 1 hour. After the dehydration step is completed, the raw material is cooled to 85±5°C, and 140.95 grams of ethylene oxide is introduced, and the pressure is controlled at 0.25±0.05MPa. The addition is completed in about 6 hours. Keep warm at ±5°C for 1 hour, complete the heat preservation, vacuum degas for 1 hour to remove unreacted traces of ethylene oxide, and then cool to obtain phenol ether monomer B 1 .

[0040] Put 10.45 grams of bottom water in a set of reactor equipped with a thermometer, agitator, dropper, nitrogen inlet pipe and reflux condensing device, turn on the nitrogen, fully exhaust the air, raise the temperature to 60±5°C, and start to drop the phenol ether Monomer B ...

example 2

[0043] Add 4-vinylphenol 35.15 into the reactor, add 2.9 grams of solid sodium methoxide, replace with nitrogen 3 times, raise the temperature to 110±5°C, turn on the vacuum pump to remove the moisture in the raw material and form methanol, the removal time is 1 hour. After the removal step is completed, the raw material is cooled to 85±5°C, and 1429.55 grams of ethylene oxide and propylene oxide mixture are introduced, and the pressure is controlled at 0.25±0.05MPa for 10 hours. After the addition is completed, keep it warm at 130±5°C for 1 hour. After the heat preservation is completed, vacuum degas for 1 hour to remove unreacted traces of ethylene oxide and then cool to obtain polyether monomer B. 2 .

[0044] 45.45 grams of bottom water are charged into a set of reactor equipped with thermometer, stirrer, dropper, nitrogen inlet pipe and reflux condensing device, polyether monomer B 2 60.20 grams, turn on the nitrogen, fully exhaust the air, after the polyether is dis...

example 3

[0047] Add 4-vinylphenol 50.15 into the reactor, add 0.24 grams of potassium hydroxide, replace with nitrogen for 3 times, raise the temperature to 110±5°C, turn on the vacuum pump to remove the moisture in the raw material under the pressure of -0.099MPa, and dehydrate The time is 1 hour. After the dehydration step is completed, the raw material is cooled to 85±5°C, and 367.25 grams of ethylene oxide is introduced, and the pressure is controlled at 0.25±0.05MPa. The addition is completed in about 7 hours. Keep warm at 5°C for 1 hour, complete the heat preservation, vacuum degas for 1 hour to remove unreacted traces of ethylene oxide, and then cool to obtain polyether monomer B 3 .

[0048] Add polyether monomer B into a set of reactor equipped with thermometer, stirrer, dropper, nitrogen inlet pipe and reflux condensing device 3 60.20 grams, 55.45 grams of deionized water, turn on the nitrogen, fully exhaust the air, raise the temperature to 60±5°C, start to drop a mixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com