Ligand compound and preparation thereof, and complex containing ligand compound

A technology of ligand compounds and complexes, applied in the preparation of imino compounds, nickel organic compounds, organic chemistry, etc., can solve the problems that late transition metal catalysts cannot meet the requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

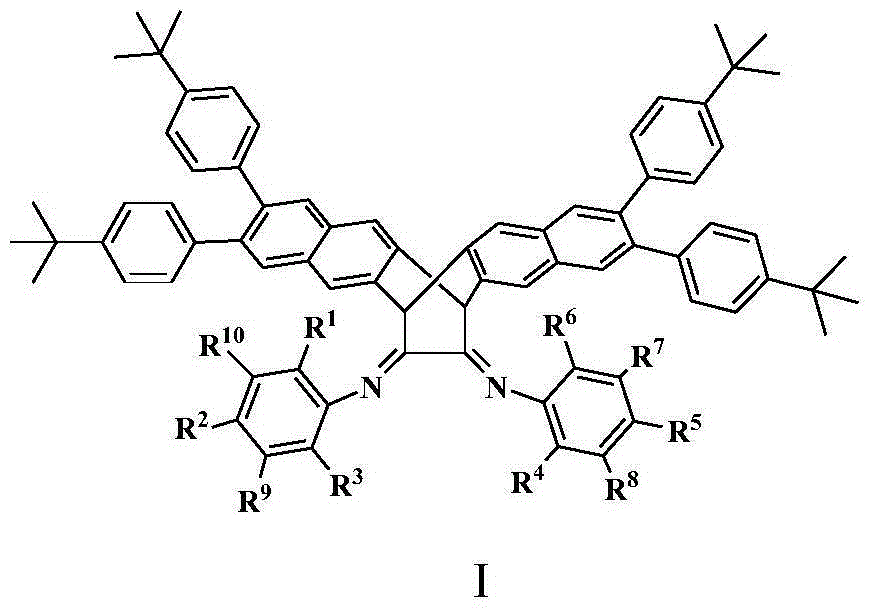

[0062] 1) preparation of ligand (R in structural formula (I) 1 , R 3 , R 4 and R 6 is methyl, R 2 , R 5 and R 7 -R 10 are hydrogen):

[0063] Compound A (4.07g, 4.8mmol) and 2,6-methylaniline (1.3ml, 10.4mmol), p-toluenesulfonic acid as a catalyst, refluxed in 100mL toluene for 1 day, removed the solvent after filtration, and the residue was treated with dichloro Methane was dissolved, and the column of perbasic alumina was rinsed with petroleum ether / ethyl acetate (20:1). The second fraction was divided into the product, and the solvent was removed to obtain a yellow solid with a yield of 81%. 1 H NMR (CDCl 3 ,δ,ppm): 1.16(s,36H), 1.86(s,12H), 5.20(s,2H), 7.08(m,22H), 7.68(m,8H).

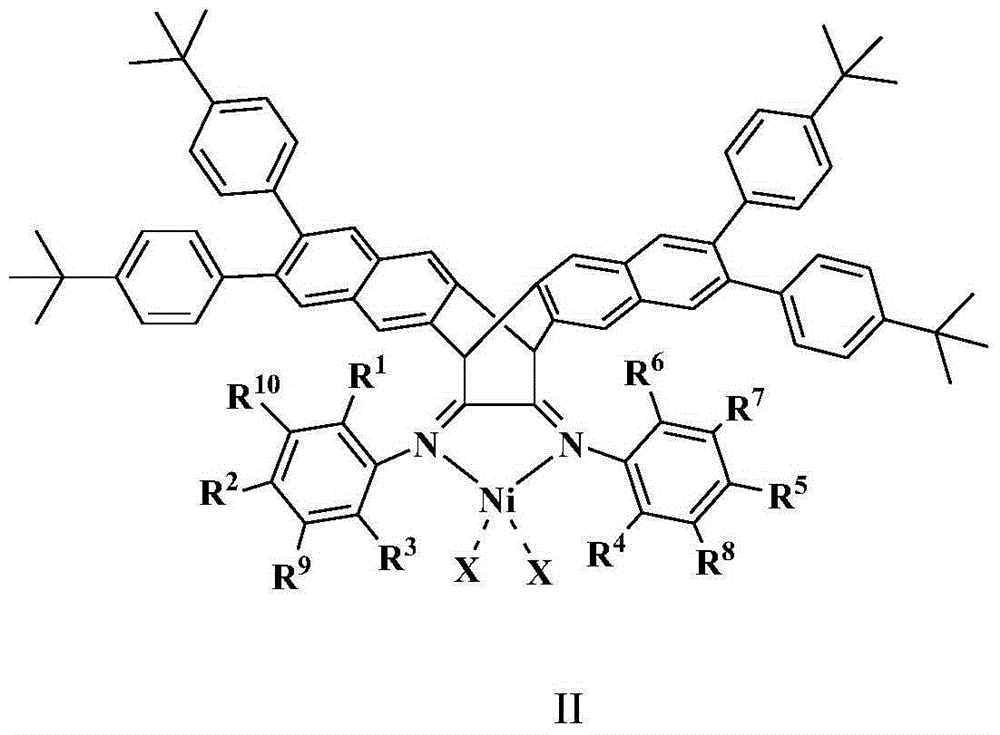

[0064] 2) Preparation of complex 1:

[0065] 10ml (DME)NiBr 2 (277mg, 0.9mmol) in dichloromethane solution was added dropwise to 10ml of the above ligand (962mg, 0.9mmol) in dichloromethane solution, stirred at room temperature for 6 hours, a precipitate precipitated, filtered, washed wi...

Embodiment 2

[0069]10atm ethylene polymerization: Dry the 1L stainless steel polymerization kettle equipped with mechanical stirring at 130°C for 6hrs continuously, vacuumize while it is hot and use N 2 Air replacement 3 times. Add 12.9 mg (10 μmol) of the complex 1 prepared in Example 1 and then evacuate and replace with ethylene three times. 500 ml of hexane was injected, and 6.5 ml of methylaluminoxane (MAO) (1.53 mol / l toluene solution) was added to make Al / Ni=1000. At 100°C, the ethylene pressure was maintained at 10 atm, and the reaction was stirred for 30 min. Neutralize with ethanol solution acidified with 5% hydrochloric acid to obtain polyethylene with a polymerization activity of 4.86×10 6 g·mol -1 (Ni)·h -1 , and the results are shown in Table 1.

Embodiment 3

[0071] 1) preparation of ligand (R in structural formula (I) 1 , R 3 , R 4 and R 6 is ethyl, R 2 , R 5 and R 7 -R 10 are hydrogen):

[0072] Compound A (6.62g, 7.8mmol) and 2,6-diethylaniline (3.0ml, 17.4mmol), p-toluenesulfonic acid as a catalyst, refluxed in 100mL toluene for 1 day, removed the solvent after filtration, and the residue was washed with di Methane chloride was dissolved, and the column of perbasic alumina was rinsed with petroleum ether / ethyl acetate (20:1). The second fraction was divided into the product, and the solvent was removed to obtain a yellow solid with a yield of 88%. 1 H NMR (CDCl 3 ,δ,ppm):1.08(t,12H,J=7.5Hz),1.16(s,36H),2.24(dd,8H,J=7.5Hz),5.20(s,2H),7.07(22H),7.68 (m,8H).

[0073] 2) Preparation of complex 2: 10ml (DME) NiBr 2 (155mg, 0.5mmol) in dichloromethane solution was added dropwise to 10ml of the above ligand (563mg, 0.5mmol) in dichloromethane solution, stirred at room temperature for 6 hours, a precipitate precipitated, fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com