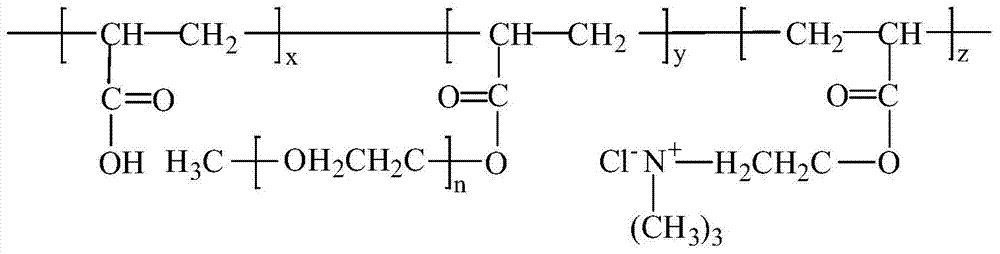

A kind of amphoteric high-performance polycarboxylate water reducer and its preparation method

A high-performance, polycarboxylic acid technology, applied in the field of preparation of amphoteric high-performance polycarboxylate water reducer, amphoteric high-performance polycarboxylate water reducer, can solve the problems of non-delay, difficult industrialization, high synthesis cost, etc. , to achieve high early compressive strength, mild reaction conditions and safe synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Preparation of cationic active organic monomer

[0030] In a four-neck round-bottom flask, add water and dimethylaminoethyl acrylate, adjust the pH of the dimethylaminoethyl acrylate solution to 7 with dilute acid, then add the polymerization inhibitor, put in the stir bar, and then install the separator. Liquid funnel, monochloromethane gas pipe and tail gas outlet pipe, at room temperature, introduce monochloromethane gas through the gas pipe first, and then stop heating and introduction of monochloromethane gas when the solution is clear. After the reaction, add Large stirring power can remove the monochloromethane gas residue in the system, and the crude product of cationic active organic monomer can be obtained after the stirring time is extended by 0.5h. The crude product obtained is extracted, washed, separated under reduced pressure and dried under vacuum to obtain a refined product of cationic active organic monomer.

[0031] Preferably, the molar ratio of wate...

Embodiment 2

[0043] It is basically the same as Example 1, except that:

[0044] Preferably, the molar ratio of water to dimethylaminoethyl acrylate in the step (1) is 1.5:1.

[0045] Preferably, the polymerization inhibitor in the step (1) is a phenothiazine polymerization inhibitor, and the amount of the phenothiazine polymerization inhibitor is 0.25% of the mass of dimethylaminoethyl acrylate.

[0046] Preferably, the molar ratio of acrylic anionic monomer, polyethylene glycol monomethyl ether acrylate and cationic active organic monomer in the step (2) is 4.0:1.0:1.

[0047] Preferably, the amount of the composite initiator of ammonium peroxodisulfate and sodium bisulfite in the step (2) is 4.0% of the total mass of the reaction monomer.

Embodiment 3

[0049] It is basically the same as Example 1, except that:

[0050] Preferably, the molar ratio of water to dimethylaminoethyl acrylate in the step (1) is 1.5:1.

[0051] Preferably, the polymerization inhibitor in the step (1) is a hydroquinone polymerization inhibitor, and the amount of the hydroquinone polymerization inhibitor is 0.50% of the mass of dimethylaminoethyl acrylate.

[0052] Preferably, in the step (2), the molar ratio of acrylic acid anionic monomer, polyethylene glycol monomethyl ether acrylate and cationic active organic monomer is 6.0:1.5:1.

[0053] Preferably, the amount of the composite initiator of ammonium peroxodisulfate and sodium bisulfite in the step (2) is 5.0% of the total mass of the reaction monomer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

| water reduction rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com